The solenoid gas gas valve for HBO with a filter is distinguished by the fact that it is capable of effectively purifying the liquid phase from gas and various tarry deposits. In addition, it is this part that is capable of shutting off the gas supply when the engine is running on gasoline, or when the ignition is turned off.

The gas filling valve is, as a rule, actively used to supply gas fuel. Again, it is important to note here that it is capable of purifying the gas mixture from various impurities. The gas equipment valve can be used for certain vehicles whose owners wish to install gas equipment.

Operating principle of the solenoid valve. Peculiarities

If we consider the static position, then at this moment the valve coil will be de-energized, moreover, the valve closes completely, but it can also be open, since everything depends on its type. As for the membrane and piston, these parts are in contact with the seat of the product.

It is important to note that as soon as electrical voltage is applied to the coil, it causes the valve to begin to open. This action begins to occur with the help of a magnetic field, which is created in the coil.

At the moment when a consumer wishes to purchase an LPG gas valve, he must understand that it will be necessary to take into account the technical characteristics, this also applies to design features. This is explained by the fact that not all existing valves will be able to direct the movement of the medium in one direction or another.

There are options that work in a certain direction of flow of the working medium. If you ignore such factors, this will lead to the products losing their functionality. So, when choosing an LPG filling valve, you need to remember: the device must be studied in detail and carefully.

How to remove the multivalve

To diagnose and identify the cause of the malfunction, remove the “cartoon” from the gas cylinder.

- You should proceed with dismantling only when there is no gas left in the cylinder.

- First, you should loosen the fastening of the gas main pipes and bleed off the remaining gas.

- After all the gas has completely left the cylinder, we begin dismantling the multivalve. To do this, unscrew all the mounting bolts. This should be done extremely carefully, since breaking the fastening bolt does not threaten anything good. If one or more bolts do not budge, treat them with penetrating lubricant and wait a few minutes.

Unscrew all the bolts and carefully remove the multivalve from the cylinder

Read also: How to transport oversized cargo

It is best to show the removed “multiple” to a specialist, who will determine whether it is possible to get by with a repair kit for the multivalve or whether this unit should be completely replaced with a new one. If you decide to replace the multivalve, you should reassemble in the reverse order.

Malfunctions. What should you know?

It should be noted that situations often arise when the LPG filling valve device fails, and the reasons can be very different. For example, if you notice that it does not work as it should, and perhaps does not respond at all, then you should study all the reasons for what is happening. Here they are:

- More and more often we have to face such a problem as the accumulation of foreign elements - this is the most common reason. All this happens due to the fact that debris begins to accumulate on the surface of the core, and this leads to the fact that the LPG valve stops working properly.

- It is necessary to take into account: with long-term use of the valve, sediment begins to appear on it. This leads to the fact that the product stops working correctly. Thus, the petrol solenoid gas gas valve requires that all points of the operating instructions be strictly followed, and when problems arise, they are immediately resolved.

- Situations often arise when the product is in good working order, it functions and works without interruptions, but the system itself does not work. Thus, it is not possible to switch from gas to gasoline.

If you encounter such a problem, then you need to carefully check the power supply to the coil of the product; perhaps there is poor contact of the power wires or oxidation of the contacts has occurred.

Attention: You should listen to the opinion of experienced specialists, because in order to avoid such troubles, you need to carry out regular maintenance of the gas equipment, and accordingly, change the filter elements on time. In addition, you need to refuel exclusively with high-quality gas by visiting proven gas stations.

Installation of the solenoid valve. Peculiarities

No one denies that the gasoline valve for gas equipment plays an important role, as does the check valve for the second LPG chamber. That is why any manipulations associated with this equipment must be carried out in a careful, high-quality manner; it is advisable that this work be carried out exclusively by specialists with extensive experience and experience.

The valve, or multi-valve, of gas equipment is considered the most important element. If you begin to notice the appearance of certain problems associated with the functioning of the gas equipment, then know: this may indicate that this valve has actually failed.

Wanting to cope with such a problem on their own, many people often face serious troubles. If this work is carried out by specialists with an arsenal of necessary tools and appropriate equipment, then many problems can be avoided.

A little earlier it was said about the main reasons for unit failure. It should be noted that it is quite possible to check the valve of a particular gas equipment in two ways: in the first case, you can always measure the current indicators, of course, at its outputs, and in the second case, you can analyze its operation. If the valve is in good working order, then know that it will always click when you turn the key in the ignition, and, of course, during the process of starting the engine.

Types of mechanism

The types of filling mechanisms can be roughly divided according to the installation method:

- remote valve on bracket;

- mechanism built into the bumper;

- assembly embedded in the standard gas tank flap.

Types of filling devices

The design of all valves is identical:

- frame;

- lid;

- ball;

- spring;

- seals.

VZU device

The solenoid valve of the geyser does not work.

The guest wrote: the gas water heater stopped turning on, the gas simply does not light up. Water flows, there is pressure in the system, the gas is open - it doesn’t light up and that’s it. The column is completely automatic, you can do it as the master explained - you don’t need anything, it works by itself, lights up and turns off. After my wife washed herself, the speaker stopped turning on.

I also don’t agree that “90% is due to dead batteries.” The reason for “Gas is open - does not light up” could also be the flow sensor; the automation simply “does not see” that there is water flow through the column. Or there could be a problem with the gas valve. You can guess for a long time.

In any case, start by replacing the batteries (if you have ignition from them), if it doesn’t help, call a specially trained person. Of course, you will have to pay for diagnostics. But he will establish the exact cause of the problems.

The solenoid valve of the geyser does not work.

There is a solution when the solenoid valve does not open. Apparently there is a weak current on the coil, and even the gas pressure “holds” the valve in the closed state, so the valve needs help (if the stem moves freely with the valve removed, it should work). You need to attach a not very strong magnet to the back wall of the valve, so that it does not open the valve on its own (in my case, it was a curtain magnet). The valve stem will be in a magnetized state, and a minimum of effort will be required to move it; it will work even with dead batteries. You can experiment with the power of the magnet.

An electromagnetic gas valve with a filter cleans the liquid phase of gas from suspended matter and tarry deposits (coarse filter) and shuts off the gas supply when the engine is running on gasoline and when the ignition is turned off.

LPG gas valve is used to supply gas fuel and to stop it. In addition, it purifies the gas mixture from all kinds of impurities. The LPG gas solenoid valve is used for all cars when installing gas equipment.

HBO valve device

Depending on the model and manufacturer, the gas turbine valve device may vary, but often consists of the following elements:

- Core;

- Valve with return spring;

- Electric coil with winding;

- Gaskets and seals;

- Coarse filter. Quite often, the LPG valve is equipped with a coarse fuel filter, but such equipment is not required.

What does all this threaten?

The very fact that, despite the decent costs of purchasing and installing liquefied petroleum gas, you have to drive on gasoline is quite annoying. After all, the owner planned to save on fuel. But that is not all.

Most of the defects presented have a negative impact on the condition of the engine. Ignoring the “Check Engine” indicator is a direct path to burnt valve seats. Ignoring deviations in the operation of the engine cooling system and internal heater leads to overheating of the block, cracking of the head and burnout of the gasket. In this case, repair costs will cost tens of thousands of rubles.

Installation and operating principle

Installation

It should be noted that different installers of gas equipment systems install different numbers of solenoid gas valves on a vehicle.

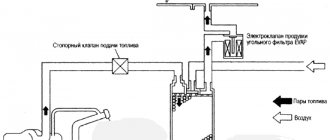

- The cheapest and most common scheme is to install one EGC directly on the evaporator reducer.

- A more expensive scheme implies the presence of two parallel gas gas valves: one is installed on the reducer, the second on the flow line of the multivalve or after the multivalve and shuts off the gas supply to the line.

- The last, most reliable and expensive option has three devices paralleled to each other: the first is still located on the gearbox, the second (backup or safety) is installed in front of the gearbox, and the third is installed on/after the multivalve, near the cylinder.

Principle of operation

The operating principle of the HBO valve is as follows:

- Initially, the HBO valve is in a closed state.

- After the car is ready to switch to gas, the ECU (or the driver pressing the “gas-gasoline” button) sends a signal (+12 v) to the EGC coil, the magnetic coil is activated, lifting the shut-off valve (a characteristic click is heard).

- After the gas solenoid valve opens, the gas enters the coarse filter, and then into the evaporator reducer.

Essential elements

Reducer-evaporator. A system element designed to heat a propane-butane mixture. It controls evaporation and reduces pressure to atmospheric pressure. Structurally, a gas reducer is a mechanism consisting of several chambers connected in series. They are separated from each other by valves.

Solenoid valve for gas. The mechanism is designed to block the fuel pipeline. This is necessary when the engine is idle, after switching to motor gasoline. The valve is additionally equipped with a fuel purification filter.

Solenoid valve for gasoline. This mechanism stops the supply of gasoline in carburetor engines when they operate on a gas mixture. The gas control unit performs a similar task in injectors.

Automotive fuel switch. This mechanism is installed inside the vehicle. Switches may differ in design. Some options have a backlight and an indicator scale that shows how much gas mixture is left in the cylinder.

Multivalve. The mechanism is located on the neck of the cylinder. Its design includes the following valves: high-speed, flow, and filling. Additionally, the multivalve is equipped with an intake tube and a fuel mixture level meter. The high-speed valve prevents gas leakage in the event of a pipeline breakdown.

Ventilation chamber. This component of the system is also located on the neck of the cylinder. A multivalve is placed in the box. The main function of this element is to remove gas vapors to the outside when a gas leak occurs in the trunk.

Gas cylinder (special container for containing liquefied gas ). It can have a toroidal or cylindrical shape. The first option provides the opportunity to place a gas container in a niche intended for storing a spare wheel. According to safety rules when operating gas cylinders, the container is filled with the gas mixture to only 80% of its maximum capacity.

Analysis of the parts of a set of fourth-generation gas equipment: what the parts of the device look like, why they are needed and how everything works

Possible malfunctions and breakdowns

Like any element of the system, the LPG gas valve is susceptible to breakdowns, and since, as we found out above, this element of the system performs a locking function, without its proper operation, the car most likely will not switch to gas. And although the cost of this system unit is not high, it is not always possible to purchase a new LPG valve, therefore, in order to repair a broken one, you need to have an idea of the most common breakdowns of this element.

Mechanism contamination

The HBO solenoid valve operates in the engine compartment, which means it is exposed to dust, dirt, rust, scale and other debris that can get inside the device, thereby preventing the valve from opening. In this case, disassembling and simply cleaning the device from foreign objects will help.

Filter clogged

Most valves that are installed in front of the gearbox have a coarse filter, which, although not directly related to valve failure, can provoke unstable operation of the entire LPG system or prevent it from switching to gas at all. In this case, the filter should be replaced. It is recommended to do this at least 2 times a year or every 10,000 km (whichever comes first).

Coil failure

A malfunction of the electromagnetic coil can be determined by measuring the resistance of the coil with a multimeter. In this case, the valve will not work and the car will not switch to gas. The coil can be replaced with a similar one by selecting a new one according to suitable parameters.

Oxidation of valve contacts or broken wire

Another fairly common breakdown is contact oxidation. This malfunction occurs especially often with the onset of the rainy season. In this case, you should check the serviceability of the wiring and carefully clean all contacts to remove oxidation. It is also quite common to encounter a break in the wiring that supplies +12v to the HBO valve coil. You can check the wire break using a tester or a car lamp.

This concludes our article, share links to our website on social networks or forums - this is the best way to help the development of our project, and if you still have any questions, feel free to ask them in the comments, and we will be happy to answer them.