Modern power plants are equipped with electronic control units that allow you to monitor the operation of all systems and receive timely information about their incorrect operation. One of the devices is an absolute pressure sensor, abbreviated as DBP. It helps ensure stable operation of the power unit, and transmits the collected data to the ECU.

In many car models equipped with a similar device, it is not difficult to find - the pressure sensor is located in the intake manifold of the engine. Here he is responsible for obtaining information about pressure changes in the intake tract. Electronics, based on the data received from it, optimizes the composition of the combustible mixture, which is sent to the combustion chamber.

Why is DBP required?

The correct operation of a small device affects the composition of the combustible mixture supplied to the pressure chamber. The absolute pressure sensor relies on the vacuum state during measurement, setting it as an absolute value. This is the basic principle of its operation.

When the information enters the electronic control unit, the optimal air density and flow rate are calculated, and after that the fuel-air mixture is prepared. The ECU transmits certain commands, based on the mass of required air obtained during the calculation, and the injectors responsible for fuel injection are adjusted.

Absolute pressure sensors have become a replacement for the flow meter, however, in some vehicle models both devices may be present at once.

Purpose and principle of operation of the absolute pressure sensor

A pressure sensor is designed to measure absolute pressure, which is the pressure of air relative to vacuum. The obtained data is used by the engine control system to calculate air density and air flow by optimizing the preparation of the air-fuel mixture. The device acts as an alternative to a flow meter, and in some car models it works in conjunction with a flow meter.

Modern sensors use two measurement technologies: micromechanical and thin film. The first is more progressive, as it gives more accurate measurements, and most sensors are made on its basis. If the engine has a turbocharger, an additional sensor is placed between the compressor and the manifold, which regulates the boost pressure in accordance with the needs of the engine, structurally identical to the MAP.

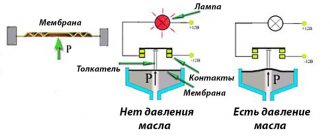

The air pressure sensor has 2 chambers: atmospheric, connected to the intake manifold, and vacuum. Also connected to the diaphragm are 4 strain gauges and an electronic chip. Air pressure acts on the diaphragm and displaces the load cells, which, depending on the position, change the resistance, which ultimately affects the pulse width from the microcircuit to the control unit.

Sensitive semiconductors are connected by a bridge to increase the pulse, and the output voltage varies from 1 to 5 V. The resulting voltage allows the ECU to determine the pressure in the intake manifold - the higher it is, the higher the indicator taken into account. Depending on the type of sensor, it produces a different type of signal: digital or analog. The analog device also contains an analog-to-digital converter.

The sensor receives the following air pressure readings:

- The air flow entering the manifold presses on the membrane of the device and bends.

- When the diaphragm is mechanically stretched, the resistance on the strain gauges changes, that is, a piezoresistive effect is observed.

- The voltage changes in proportion to the resistance of the strain gauges.

- The semiconductors in the sensor are jumpered and are very sensitive. The electrical circuit located in the device amplifies the bridge voltage, as a result, the output varies within 1-5 V.

- Based on the output voltage supplied to the control unit, the pressure level at the intake valve is calculated. Higher voltage corresponds to higher pressure.

How does DBP work?

By receiving readings from the absolute pressure sensor, the electronics control the volume of air mass entering through the throttle valve. This indicator is needed to generate a certain impulse command, allowing the amount of fuel to be calculated.

The device is a vacuum chamber from which air has been completely removed. The pressure readings in the inlet fitting are correlated with the level in this chamber, the readings are compared and the difference determines the outgoing command.

In this case, a number of manipulations are performed:

- The diaphragm of the device, characterized by a high degree of sensitivity, is deformed due to the pressure of the intake manifold influencing it;

- deformation is responsible for fluctuations in the resistance of surface position strain gauges. This effect is called “piezoresistive”;

- proportional to changes in resistance, the voltage also fluctuates, the output lies in the range from one to 5 V;

- the incoming voltage helps to form a command-pulse, which is transmitted to the injectors. This is how the pressure at the intake valve is determined, it is proportional to the voltage.

As a result, the power plant receives a certain dose of the fuel-air mixture.

Common MAP Trouble Codes

Below is a list of MAP sensor related codes to look for if your check engine light comes on:

- P0068: MAP/MAF - throttle position correlation;

- P0069: Manifold Absolute Pressure - Correlation with Barometric Pressure;

- P0105: MAP circuit failure;

- P0106: MAP Circuit/Barometric Pressure Range Problem/Performance Problem;

- P0107: Manifold absolute pressure/barometric pressure circuit low input;

- P0108: MAP Pressure Circuit High Input;

- P0109: MAP/barometric pressure circuit interrupted;

- P1106: MAP Circuit/Barometric Pressure Range/Performance Problem;

- P1107: Barometric Pressure Sensor Circuit Low Voltage.

Note: Sometimes other sensors or other faulty parts can cause these codes to appear. Even if your engine is experiencing the symptoms listed above and is setting one or more of the OBD-II codes listed, it is recommended that you check the MAP to ensure it is faulty.

Instrument location

Having figured out what DBP is, you need to determine where to look for it in the car. This type of device is used only on cars that are equipped with injection engines, especially if they also have a compressor and turbocharging system.

Often the device is located on the intake manifold; in addition, there are models where it is attached directly to the body in the engine compartment, and the inlet manifold and fitting are connected with a flexible hose.

Even if the car does not have a mass air flow sensor, DBP can be installed and perform the tasks assigned to it.

MEASUREMENT RANGES

| Range | Model "EMIS - BAR" |

| 0…25 kPa | 133 |

| 0…500 kPa | 133 |

| 0…3 MPa | 133 |

| 0…10 MPa | 133 |

| 0…25 kPa | 123, 175, 176 |

| 0…130 kPa | 123, 175, 176 |

| 0…500 kPa | 123, 175, 176 |

| 0…3 MPa | 123, 175, 176 |

| 0…16 MPa | 123, 175, 176 |

| 0…40 MPa | 123, 175, 176 |

Sensor malfunction: what indicates a breakdown

Correct functioning of the device affects vehicle control and comfortable driving. Signs of a sensor malfunction include the following symptoms:

- increase in fuel consumption. Incorrect pressure data received by the electronic control unit forces a more saturated fuel mixture to be supplied, which affects fuel consumption;

- in the hot season, the exhaust is whitish;

- the dynamics of the power unit deteriorate, warming up does not improve the situation in any way;

- the exhaust smells noticeably of gasoline;

- idle speed does not decrease for a significant time;

- noises arise, the engine hums;

- gear shifting is accompanied by jerks.

Such unpleasant phenomena most often indicate a malfunction of the sensor. In this case, diagnostics is needed.

What to look for in a faulty MAP sensor?

A faulty MAP will affect the air/fuel ratio of the engine. If the composition of the mixture is not correct, then detonation combustion is possible. If detonation continues for a long time, the internal parts of the engine (such as pistons, rings) will be damaged, and this will ultimately lead to catastrophic failure. Please pay attention to these warning events:

- Rich composition: rough idling, excessive fuel consumption, black smoke, poor acceleration and a strong smell of unburned fuel (especially at idle);

- Poor composition: operation in waves, stalling, lack of power, weak acceleration, “sneezing” reverse emissions to the intake, overheating of the converter;

- Detonation and misfire;

- Malfunction lamps in the engine control system (Check Engine).

Repairing an engine is a lot more hassle than replacing a sensor, so if your engine has any of the above symptoms, have your MAP sensor diagnosed.

Diagnostic measures

How to check the absolute pressure sensor and determine that it is working:

- first, connect an adapter for a pressure gauge to the vacuum hose connecting the device and the inlet manifold;

- The power unit is allowed to idle for some time. If there is a vacuum in the manifold - readings below 529 mm, you need to make sure that there is no damage to the hose, there are no defects in the sensor diaphragm;

- Having received the data from the pressure gauge, it is disconnected and a vacuum pump is installed in its place. A rarefied state is created (55–56 mm), after which pumping stops. If the state is held for about thirty seconds, then the sensor is working properly, and the problems with the car lie in something else. Otherwise, the faulty device must be replaced.

If the device is digital, diagnostics occurs somewhat differently:

- the tester is switched to voltmeter mode, a wire installed on the output contact of the device being diagnosed is connected to it;

- the power plant starts. If the voltage is maintained at 2.5 V, then the sensor is working, but if it deviates to one side or the other, it requires replacement;

- in tachometer mode and with the vacuum hose disconnected, the positive probe is connected to the signal terminal, and the negative probe is connected to ground. If the cause of the malfunction is not in the DBP, then the tachometer will show a value of 4400–4900 rpm;

- After connecting the vacuum pump, you can determine whether there are changes in the readings obtained by the tachometer. If they are, then you should consider replacing them.

Diagnostic measures indicate whether it is worth preparing for a complete replacement or whether cleaning the sensor is sufficient.

Repair

What should be done in case of minor malfunctions of the absolute pressure sensor? It should be said that minor repair work is within the capabilities of the average car owner. If the sensor has serious faults, then there are no other options other than completely replacing it. But replacing the device is within the capabilities of the car owner himself. To do this, you need to know where the sensor is located. It is necessary to disconnect the hose between the manifold and the sensor, disconnect the set of wires and remove the fasteners in the form of bolts. Next, you need to replace the sensor with a new one, performing all the operations in reverse.

If minor defects are present, the following operations are permissible:

- First of all, as described above, the sensor is removed. After removing the outer casing, you need to look for visible signs of malfunction.

- If dirt, rust, etc. are present, they should be cleaned. Next you need to check the electrical contacts. After all manipulations, you need to dry the device.

- After all cleaning procedures, it is recommended to use silicone sealant in the fastening areas and longer drying in warm conditions.

- Only after 24 hours is it possible to assemble the sensor parts. During assembly, special attention should be paid to the tightness of the fastening.

After all the manipulations, you should immediately check the functionality of the sensor. Start the car, if the start went without any incidents, then we can assume that the minor repairs were successful. Otherwise, you can be sure that there is a serious malfunction of the sensor, and the problem should be resolved by contacting specialists.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

How to clean DBP

During operation, the device gradually becomes overgrown with dirt, which reduces the sensitivity of the diaphragm. Because of this, symptoms may be observed that indicate a malfunction of the DBP. To clean it from contaminants, it is necessary to dismantle it.

Depending on the model of the car, the location of the sensor changes. If the engine is turbocharged, then there may be two of them, one of which will be located on the turbine, and the second on the intake manifold. In any case, bolts will be used for fastening - one or two, depending on the design.

To clean the sensor, you should stock up on carb cleaners or similar cleaning products. First, the housing is tidied up, and then the contacts are carefully cleaned. The most attention is paid to the O-ring and diaphragm. You need to be careful with them, the main thing is to prevent damage. It is enough to spray a certain amount of cleaning composition and then pour it out with the dirt removed.

Cleaning allows you to restore sensitivity to the sensors, and if the problem was only contamination, diagnostics will show that the sensor is in perfect order, and the engine will operate in standard mode. If the manipulations do not help, you should purchase a new replacement device.

Why do MAP sensors fail?

Like most electrical sensors, MAPs are sensitive to contamination. If a hose is used to connect the MAP, it may become clogged or leaky, which will lead to an error in sensor measurement or, in general, to the impossibility of this. In some cases, extreme vibrations from driving can loosen connections and cause external damage. Electrical connectors can also melt or crack from overheating due to their close proximity to the engine. In any of these cases the MAP must be replaced.

Where can I buy

Spare parts and other products for the car are easily available for purchase at auto stores in your city. But there is another option that has recently received significant improvements. You no longer need to wait a long time for a parcel from China: the AliExpress online store now offers the opportunity to ship from transshipment warehouses located in various countries. For example, when ordering, you can specify the “Delivery from the Russian Federation” option.

Follow the links and choose:

| Intake air pressure sensor 4Bar for Renault, Peugeot, KIA, Hyundai, Citroen | GKFLY car jump starter, external battery | Car charger, 2 USB ports, 5 V, 3.1 A |

| EANOP HUD car display, windshield projector | Baseus car humidifier | Car automatic parking sensors with 4 sensors |