Automatic AT or AMT: gearbox features

First of all, initially cars were equipped with only two types of gearboxes: traditional mechanics and hydromechanical automatic transmission (aka AT). However, later CVT variators appeared, as well as, relatively recently, robotic gearboxes (AMT and preselective manual transmissions).

As for AMT, we immediately note that a robotic transmission of this type is actually a mechanic

Manual transmission

, which works without driver participation, that is, gears are switched automatically. It is noteworthy that attempts to automate mechanics were made quite a long time ago, but only thanks to modern technologies and the active introduction of electronics was it possible to implement such a task.

If we talk about AT, this type of gearbox appeared a little later than manual transmission. For a long time, such a box remained the only type of automatic transmission, thanks to which, to this day, it continues to be one of the most common types of automatic transmission.

- Now let's look at the classic automatic transmission and the relatively recently appeared robots such as AMT in more detail. Let's start with a traditional slot machine.

So, a hydromechanical automatic transmission is a complex and expensive device that combines elements of hydraulics, mechanics and electronics. An automatic transmission, unlike a CVT, is a step-type gearbox, that is, it has fixed gears.

Such a box did not receive the usual mechanical clutch, since the torque from the internal combustion engine is transmitted to the transmission through a special device (“donut” automatic transmission or torque converter).

ATF (automatic transmission oil) plays an important role in such machines. This liquid is not just a lubricant, but a working fluid. The torque converter converts torque and then transmits it to the gearbox through liquid.

Also, transmission oil is supplied to the automatic transmission under pressure through channels

valve body

, that is, ATF acts on the actuators to engage gears. Redistribution of fluid flows occurs by opening and closing valves (solenoids), the operation of which is controlled by

Automatic transmission ECU

.

The advantages of automatic transmission include fairly high comfort, smooth operation and reliability of the box. A working AT gearbox changes gears almost imperceptibly, operates quietly, without unnecessary noise or vibration.

At the same time, a classic automatic transmission (taking into account the peculiarities of its design and operation) requires a large amount of transmission oil and is sensitive to the quality of ATF and the condition of the fluid. Also, the unit is not designed for constant high loads, it is “afraid” of prolonged slipping, sudden starts, and driving at high speeds.

The presence of a torque converter also means that the efficiency of such a box is slightly lower compared to analogues (by 10-15%), which means increased fuel consumption and losses in acceleration dynamics.

The average service life of such automatic transmissions is 200-250 thousand km, but only subject to timely and high-quality maintenance, as well as compliance with a number of rules within the framework of the operation of vehicles equipped with an automatic transmission of this type. Let us also add that repairing automatic transmissions is also often difficult and expensive.

Design and principle of operation

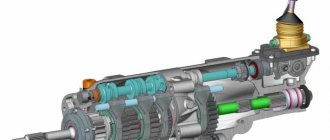

Many users do not fully understand the operating principle of the robotic box, considering it a complex mechanism. Structurally, the Lada 5 AMT gearbox is nothing more than a 5-speed manual gearbox, controlled by electronics.

So, let’s look at what 5 AMT is in detail. A detailed examination of the box produced by AvtoVAZ PJSC indicates that a standard mechanical-type automated transmission scheme is used using one disc in the friction clutch design.

The layout looks like this:

- Box clutch;

- Variable gearbox, mechanical type;

- Gearbox and clutch drives;

- Box control module.

A special device, mechatronics, is responsible for controlling the gears. Since it is a set of control elements in the form of sensors and electronics, the design does not provide mechanical connections for shifting gears.

It includes:

- Variable gearbox speed sensor on the input shaft;

- Gearbox mode control selector;

- An actuator that controls gear shifting and clutch release;

- Gearbox controller.

The gearbox operates in one of two modes: automatic and semi-automatic. Receiving information from sensors, in automatic mode the box changes gears without driver intervention. Gears are switched using software and signals from the control module. In manual mode, gears are changed by the driver using the shift lever. Move forward, upshift, move backward, downshift.

Since 2012, Lada cars have been equipped with the Japanese 4 AT gearbox, produced by Jatco. This is a classic four-speed automatic transmission equipped with a hydraulic transformer. Buyers were faced with the question, 4 AT or 5 AMT, which is better, what to choose and how will this affect further operation? The automatic transmission had a number of advantages related to smoothness and comfort. However, there were more disadvantages: increased fuel consumption, expensive and complex maintenance. Over time, the robot became popular among car enthusiasts.

ADVANTAGES AND DISADVANTAGES OF AUTOMATIC TRANSMISSION

The Lada Granta/Kalina 2 is equipped with a Jatco automatic transmission; this gearbox has been installed on Nissan for more than two decades and has proven itself well during this time. Reviews from owners of Lada Granta with automatic transmission indicate that the automatic transmission shifts gears smoothly, on time and accurately. There is no excessive thoughtfulness, and sudden accelerations and braking do not confuse her.

The disadvantages of the machine include high fuel consumption

, especially in urban areas, as well as very expensive repairs.

What cars can it be installed on?

The first car under the Lada Priora brand, equipped with AMT, was released in 2014; the installed gearbox was modified AMT-2182. After running in and finalizing the mechanisms and program elements, automatic mechanical transmissions began to be equipped with the Lada Granta, this happened in March 2022, and the Lada Vesta, in 2022. The Lada Kalina and Lada Xray cars were equipped with the same gearbox.

Later modifications of the gearboxes are structurally similar to the first gearbox released by the company. The difference lies in the improved program of the latest version, which was developed by the German company ZF Friedrichshafen AG. The principle is based on the use of a new transmission switching algorithm and improved functional logic. AMT has a number of operational features and is characterized as a simple, reliable, economical unit.

Which models are equipped with an AMT gearbox?

This robot is installed on Lada cars only with 16-valve power units:

Lada

| Vesta sedan 2180 | 2015 – present |

| Vesta SV 2181 | 2017 – present |

| Vesta Cross 2180 | 2018 – present |

| Vesta SV Cross 2181 | 2017 – present |

| Granta sedan 2190 | 2015 – present |

| Granta hatchback 2192 | 2018 – present |

| Granta liftback 2191 | 2018 – present |

| Grant station wagon 2194 | 2018 – present |

| Granta Cross 2194 | 2019 – present |

| X-ray hatchback | 2016 – present |

| Priora sedan 2170 | 2014 – 2015 |

| Priora hatchback 2172 | 2014 – 2015 |

| Priora station wagon 2171 | 2014 – 2015 |

| Kalina 2 hatchback 2192 | 2015 – 2018 |

| Kalina 2 station wagon 2194 | 2015 – 2018 |

| Kalina 2 Cross 2194 | 2015 – 2018 |

Variable speed drive

CVT gearbox is a variation of “automation”. However, its design and operating principle differ significantly from the classic automatic transmission. This is a continuously variable transmission, which includes:

the variator itself; the unit that disconnects the engine from the variator; control system; reverse mechanism.

CVT gearbox can be of two types:

The operating principle is based on the fact that two sliding pulleys (driver and driven), connected by a metal belt, automatically change their diameter, thereby changing the gear ratio. The variator is started using the selector lever. Transmission modes are identical to automatic transmissions.

Positive aspects of the variator over other gearboxes:

efficiency when using engine power; high fuel economy; comfortable operation and movement; smooth running of the car; smooth acceleration and rapid acceleration; low load on the engine; environmental friendliness; high efficiency.

If you still decide to give preference to the CVT, then it is worth considering its disadvantages:

complexity of design and repair, purchasing spare parts; small number of services capable of carrying out repairs; rapid wear when driving on bad roads and off-road; specific noise during operation; short service life; not installed on powerful cars.

Important! Experienced car mechanics and car enthusiasts advise against purchasing a car with a CVT that has already been used. If the purchase has already been made, then it is necessary to completely replace the oil, speed sensors and fuel level in a timely manner.

How does the AT box work?

AT is an automatic transmission that uses an automatic gearbox (automatic transmission), which makes driving easier. The driver does not have to change gears when changing speed - everything happens automatically.

In Europe and the USA, more than 80% of cars sold are equipped with an AT transmission, in Russia - about 50%. Moreover, in the premium segment, 80% of all cars are equipped with an automatic transmission.

Box device

If the car has an AT transmission, the speeds are switched in automatic mode, the operation of which is provided by a hydraulic transformer.

- hydraulic transformer - transmits force from the engine to the wheels;

- planetary gear - transmits torque to automatic transmission elements;

- friction clutch - changes gears after receiving a signal from the ECU;

- overrunning clutch - protects automatic transmission parts and friction clutch from mechanical damage;

- connecting mechanisms - different shafts, drums and gears.

Operating principle

The first automatic transmissions appeared in the 30s of the last century. The design of modern machines has moved far from the first units, but the principle of their operation has hardly changed.

The automatic transmission is conventionally divided into three parts:

- hydraulic - it is responsible for transmitting torque;

- electronic - switches modes and provides communication with vehicle systems;

- mechanical - switches speeds.

- When the engine turns on, oil enters the transformer and the pressure increases. The pump ring begins to rotate. Once the speed is activated and fuel flows through the accelerator, the “supercharger” accelerates.

- Thanks to the working fluid, rotation starts. Its flow alternately starts the wheels - reactor and turbine.

- The wheels of the car begin to move due to the torque. After reaching a certain level of speed, the elements make the same movement. The liquid entering the reactor ensures its rotation, and the system operates like a hydraulic coupling. When resistance increases, for example when going up, the unit stops moving.

- When a certain speed level is reached, a gear shift occurs. The ECU sends a signal to stop the downshift. It switches without loss of efficiency due to the presence of oil in the valve. When the speed decreases, the transmission switches in the opposite direction.

When the engine stalls, the pressure in the torque converter is lost, so it is impossible to start the car by “pushing”.

Advantages and disadvantages

AT and automatic transmissions have a lot of advantages, which is why they are widely implemented in modern cars. But if this system were flawless, they would not produce AMT.

- comfortable control;

- increased traffic safety - the driver does not have to be distracted by changing gears;

- driving comfort - in a car with an automatic transmission there are no problems when starting and stopping, as in a manual transmission;

- engine wear is reduced.

Many drivers of cars with MT have been in a situation where they, having forgotten that the car was at speed, turned on the ignition. As a result, the car made a “jump” forward. This cannot happen in a car with AT.

- higher cost of the car;

- high fuel consumption;

- Automatic transmission requires careful care - you need to change the oil often, etc.;

- expensive repairs;

- low efficiency;

- there are features of using 4AT in winter;

- If the battery is discharged, the car will not be able to be started “from the pusher”.

During each technical inspection, it is recommended to calibrate the automatic transmission to increase its service life.

Advantages and disadvantages

Comparing the transmission with other representatives of automatic transmissions, we can highlight both positive and negative features of the box.

Advantages of the 5 AMT unit:

- Reduced fuel consumption, performance comparable to a 5 MT manual transmission;

- Low cost of spare parts and labor in case of gearbox repair;

- The design of the box allows you to tow the car using a cable or a rigid hitch;

- If the battery loses power, the box allows you to start the car from a pusher;

- The friction disc and gearbox lubricants are designed for the entire service life of the product;

- Protection of the box from incorrect switching, which avoids damage;

- The box has automatic and manual gear shifting;

- Smooth operation of the gas pedal facilitates the transition from gear to gear without jerks or failures;

- Switching occurs in a short period of time, within 120 ms;

- The presence of an automatic algorithm that allows you to start moving the machine while on an inclined surface.

Gear shift process

In a manual transmission, starting from the neutral point (N) of the gear lever, the gear shifting process can be divided into two phases:

- gear selection (also called direction selection): when the appropriate transmission plane/line is selected;

- gear engagement : when the upcoming gear is actually engaged

For example, to engage 1st gear, the gear shift lever is first moved to the left in the 1-2 plane and then pushed forward.

Since gear engagement is a combination of two movements along different axes, an automated transmission requires:

- 2 drives for gear shifting;

- 1 clutch on/off actuator;

An actuator can be defined as a device that converts an electrical signal (sent by an electronic control module) into a physical action (translation or rotation). Actuators can be a solenoid valve that regulates fluid pressure, or an electric motor that rotates a gear.

Price of VAZ AMT robotic gearbox

It is very difficult to buy a new or at least used manual transmission 2182 at this point in time, just as there are practically nowhere qualified specialists for repairing such transmissions. Therefore, owners of out-of-warranty cars with a robot are left with a large-unit replacement.

The cost of spare parts for restoring the VAZ 2182 or AMT robotic transmission:

| Box VAZ 2180 | RUB 38,450 |

| ZF gear shift actuator | RUR 56,643 |

| ZF Clutch Actuator | RUB 35,756 |

| Large-unit replacement work (on average) | RUB 9,350 |

The price of parts for just such a box is briefly discussed in this review.

You can contact the site administrator by email:

All texts were written by me, are authored by Google, included in the original Yandex texts and notarized. For any borrowing, we immediately write an official letter on company letterhead in support of search networks, your hosting and domain registrar.

Next we go to court. Don’t try your luck, we have more than thirty successful Internet projects and have already won a dozen lawsuits.

5 AMT transmission service

According to the manufacturer, the 5 AMT transmission does not require maintenance, its elements are protected from dust and moisture, which in turn has secured the transmission’s reputation as a simple, reliable, trouble-free mechanism.

However, it is recommended to adhere to the following rules:

- Monitor the oil level; mechanical damage to the box may cause it to leak;

- Adapt the robotic gearbox clutch in a timely manner.

The box is a set of gears controlled by a ZF actuator. The clutch of the box wears out over time and needs to be adjusted to the actuator, this process is called adaptation, it is designed to eliminate jerks and shocks when moving.

Adaptation is carried out:

- Every 15,000 km of vehicle mileage;

- In case of clutch replacement;

- When updating the on-board computer settings.

The process is simple and takes a few minutes: the car is connected to the AvtoVAZ computer through a special diagnostic connector, the electrician turns on the program and directly communicates with the manufacturer’s server. The data is downloaded to the server, after which the engine starts and adaptation occurs within a few seconds.

It is advisable to have the box diagnosed by an official representative, since the work will require special equipment and trained personnel.

As you know, today all automatic transmissions are usually called automatic transmissions. In this case, “automatic” can be called either a classic hydromechanical gearbox with torque converters, or a CVT variator or a robotic manual transmission.

Taking into account the fact that a robotic gearbox can also be represented by two types of gearboxes (for example, a semi-automatic manual AMT and a preselective gearbox of the DSG type), many motorists often have difficulties when choosing an automatic transmission.

Next, we will separately consider what AT and AMT are, what advantages and disadvantages these types of gearboxes have, and also what you should pay attention to when choosing a car with one type of automatic transmission or another.

Read in this article

Which is better to choose?

For novice motorists, when buying a car, it is useful to understand the issue of gearboxes. Many people prefer to learn on cars with a conventional 5MT transmission (like in a Lada), but later buy modern cars with a 5AMT or AT transmission.

Having understood the difference between AT and AMT boxes, you can consciously choose the option that is optimal for your driving style, driving skills and preferences.

What you need to pay attention to when choosing:

- A car with an automatic transmission has only two pedals - gas and brake, and you do not need to constantly move the gearshift knob. But the AMT box retains all the advantages of a manual transmission - cost, economical fuel consumption and full control over the car.

- Automatic transmission requires a large amount of gear oil, it is sensitive to the quality of ATF and its condition. The unit does not tolerate constant high loads and prolonged slipping, sudden starts and driving at high speeds. But with AMT there are no such problems.

- The efficiency of a car with AT is 10-15% lower than that of cars with other types of gearboxes.

Cars with AMT are suitable for drivers who prefer a calm and moderate driving style. Fans of high speeds and sharp maneuvers are unlikely to like the robotic gearbox. AT is recommended for those who want to completely shift gear shifting to automatic mode in order to concentrate on driving the car. By understanding what AT and MT mean in a car, you will be able to make the right and informed choice.

How does the AMT box work?

AMT is a gearbox installed today on many foreign and domestic vehicles. Such devices are often installed on sports cars. Experts believe that AMT will become most widespread in the future and will be more popular than an automatic transmission (automatic or AT).

What elements are included?

Essentially, AMT is a manual transmission, a reliable and decades-proven device that provides automatic switching. Simply put, AMT is a cross between a manual and an automatic.

The robotic box includes the following elements:

- Manual transmission (manual transmission);

- ECU (electronic control unit);

- clutch;

- drive connecting the clutch and gears;

- other nodes.

Cars equipped with a “robot” also have a large number of different sensors, thanks to which the speed is switched at the right moment.

The following sensors are installed in cars with AMT:

- ABS - refers to the anti-lock system;

- sensor that controls crankshaft rotation;

- ESP - responsible for electronic stabilization and others.

Unlike cars with manual transmission, “robots” constantly monitor the temperature inside the AMT using special temperature sensors.

Operating principle

The abbreviation AMT stands for automated manual transmission. Motorists call such a box a “robot”.

- The gearbox is manual, but the driver does not have to depress the clutch or change gears - all these manipulations are performed automatically based on computer calculations

- The on-board computer, having analyzed the speed, ABS sensor readings and other data from various vehicle systems, initiates gear shifting. This action is performed by devices that transmit force - actuators.

- AMT boxes can operate in automatic or semi-automatic mode. With full automatic switching occurs automatically. In semi-automatic mode, speeds are switched manually. A person driving a car uses the Tiptronic automatic transmission function. In this mode, the speed is changed using a lever or using switches located under the steering wheel.

The cheapest and most common option is a robotic box. Its disadvantage is its reaction speed. Similar AMTs are installed on budget cars, which tarnish the reputation of robotic boxes.

- Start the engine.

- The power flow is disrupted by the clutch.

- Speed selection.

- The clutch engages.

- The revolutions gradually increase by pressing the gas pedal.

- The car starts to move.

Pros and cons of the AMT box

The transmission, which combines manual and automatic transmission, like any automotive unit, is a complex system that has certain characteristics and has a number of advantages over AT transmission and conventional mechanics.

- reliable mechanical part;

- endurance and long service life;

- friction clutch reduces fuel consumption;

- low transmission oil consumption compared to an automatic transmission - AMT requires 4 liters, AT - 8 liters;

- the mechanical part is repairable;

- possibility of control in semi-automatic mode.

Thanks to the semi-automatic mode, the driver can take part in the operation of the system if a difficult driving situation arises - a traffic jam, bad road, traffic lights, climbs, steep descents, etc.

Robotic boxes are very popular among motorists today. Designers are constantly improving the operation and technical characteristics of the unit. But AMT also has a number of disadvantages, which are useful to know about for those who do not know which box to prefer.

- you cannot reflash the processor or program a different algorithm to increase, for example, the dynamics of a car;

- reduction of switching speed;

- The clutch often slips;

- at low speeds (on hills or in traffic jams), the transmission overheats;

- When switching speeds in auto mode, jerking may be observed.

One of the most unpleasant situations that can happen to an AMT on the road is clutch overheating. To prevent this, it is recommended to set the transmission to neutral speed when stopping for more than 10 seconds.

AMT gearbox: what is it?

The debate between fans of manual and automatic transmissions has not subsided for a couple of decades. Each of these two types of transmission has its own advantages and certain disadvantages.

But in recent years, a gearbox has appeared that can combine the main advantages of automatic and manual transmissions. This is an AMT gearbox, also known as a robot or robotic gearbox. In this article we will talk about what an AMT gearbox is, how it works and what its advantages and disadvantages are.

What's the result?

As you can see, it is quite difficult to unequivocally answer the question of which is better, AT or AMT. On the one hand, low production costs make the AMT robot more affordable. However, we should not forget that comfort and reliability in this case will suffer somewhat.

It is also a mistake to rely on the simplicity and maintainability of a manual transmission when choosing an AMT, since replacing servomechanisms, actuators and clutches in the case of a robot turns out to be quite costly operations.

If the need for repairs arises, you should be prepared for serious expenses. As a rule, this applies not only to the box itself, but also to the torque converter. Finally, we note that today a more worthy alternative to the classic AT can no longer be considered an AMT, but a robotic gearbox with a dual clutch (such as DSG or Powershift).

Such a box is a symbiosis of an automatic machine and a robot, and is devoid of the main disadvantages of AMT. However, the disadvantages can be considered high cost, average reliability, low maintainability and disadvantages that are borrowed from the classic machine gun.

As for AMT, such a gearbox today is often installed on budget city cars and is suitable for quiet driving in automatic mode with the ability to switch to manual control. It turns out that the AMT gearbox allows you to provide more comfort than a manual transmission, but in a number of indicators the AT automatic gearbox falls far short of a full-fledged gearbox.

How to use a robotic gearbox correctly: “single-disc” robot, preselective robotic gearbox with two clutches. Recommendations.

What is the difference between a CVT transmission and an automatic transmission or robot transmission: the main differences between CVT and automatic transmission, as well as robotic transmissions such as AMT or DSG.

Manual or automatic transmission: which gearbox is better, manual transmission or automatic transmission. Features of manual and automatic transmission, recommendations.

What is the difference between a “classic” automatic transmission with a torque converter and a robotic gearbox with one clutch and preselective robots such as DSG.

What is better to choose, an automatic transmission with a torque converter or a robotic gearbox with one or two clutches. Pros and cons of these types of boxes, recommendations.

Robot gearbox: what manual transmissions are there, the strengths and weaknesses of robotic gearboxes. What to consider when purchasing and operating a robot.

The AMT gearbox is not as popular as a manual or automatic transmission, although it combines both types of transmissions. What is it, what types of AMTs are there and how to ride them?

To transmit torque from the engine to the wheels, the car has a special device - a gearbox or transmission.

It can be mechanical, automatic, robotic or CVT.

The first three are stepped, that is, they have the usual first, second and other speeds, the last is stepless and works on a different principle.

The AMT gearbox is installed on many modern cars, including Russian-made cars.

Advanced models of such gearboxes are also found on sports cars.

There is an opinion that in the future AMT will become more widespread than automatic transmissions and will completely replace manual transmissions.

About double clutch

Earlier in the article we mentioned German Volkswagen cars with their selective gearboxes. Recently they have become very popular. And all thanks to the use of a dual clutch system. This device allows you to quickly change gears with minimal loss in dynamics. And all this without the use of an expensive hydraulic drive. They were called preselective due to their special operating principle.

When the car is moving in one gear, the second disc is already engaged with the next one. Thus, when the car needs to switch to higher speed, this process is carried out as quickly as possible. Moreover, the system works not only to upshift, but also to downshift. The car “resets” them very quickly when braking. The design of such AMTs is very compact, which is especially important for small cars. There are two types of clutch used here. It's wet and dry.

Let's look at the technical characteristics using the example of a 7-speed AMT. An electric pump is installed here. The oil volume in the system is 1.7 liters. The peak torque of this transmission is 250 Nm.

This is quite enough for passenger cars. But as for SUVs, they lack such characteristics for acceleration. Therefore, a wet clutch type is used here (oil volume is 6.5 liters). But the torque here is much higher – 350 Nm. In any case, the use of a double clutch allows you to change gears without noticeable dips in dynamics.

Now this type of gearbox is used on German-made cars, in particular on Volkswagens. Also, Skoda cars are equipped with an AMT gearbox. What it is? This is a six-speed robotic transmission with two clutches. The manufacturer gives it a five-year warranty.

AMT gearbox - what is it?

The AMT gearbox is not as popular as a manual or automatic transmission, although it combines both types of transmissions. What is it, what types of AMTs are there and how to ride them?

To transmit torque from the engine to the wheels, the car has a special device - a gearbox or transmission.

It can be mechanical, automatic, robotic or CVT.

The first three are stepped, that is, they have the usual first, second and other speeds, the last is stepless and works on a different principle.

The AMT gearbox is installed on many modern cars, including Russian-made cars.

Advanced models of such gearboxes are also found on sports cars.

There is an opinion that in the future AMT will become more widespread than automatic transmissions and will completely replace manual transmissions.

Automatic transmission

A classic automatic transmission (AT) consists of a hydrodynamic transformer (HDT), a mechanical part, which includes friction clutches, brakes and planetary gears, and an electronic control system that changes gears without driver intervention. Let us recall that the torque converter consists of a pump wheel connected to the engine crankshaft, a turbine wheel connected to the input shaft of the mechanical part of the gearbox, and a reactor, the blades of which direct the working fluid from the pump wheel to the turbine wheel. The shape of the reactor blades is selected depending on the required transformation ratio (increase in torque).

AMT management

During operation, the “robot” is much simpler than automatic transmission and classic “mechanics”. The electronic selector allows you to use 4 operating modes:

- neutral - N;

- automatic - A;

- reverse - R;

- manual control - M.

Before you start driving, you need to set the selector lever to position “A”, then press the brake pedal and only then put your foot on the gas pedal.

Attention! The engine of a LADA Granta (sedan, liftback) equipped with a “robot” will not start if you forget to press the brake pedal.

The car's acceleration time to a speed of 100 km/h is 12.5 seconds, which is 1.6 seconds inferior to models with a manual transmission (10.9 seconds), but 0.8 seconds better than the LADA Granta with automatic transmission (13. 3 sec.). In this case, gear shifting occurs at 5000 rpm for aggressive driving or 2500 rpm for quiet driving.

The time to switch from one gear to another in automatic mode is no more than 2 seconds. Because of this, AMT may seem “thoughtful” to some drivers, but when switching to manual control mode, the gear shift speed is comparable to the speed of a manual transmission.

AMT box: pros and cons

Now back to AMT (automated manual transmission). First of all, the AMT gearbox is also capable of shifting gears automatically. However, in terms of design and operating principles, the solution is very different from AT.

As mentioned above, AMT is much closer to a manual transmission. In fact, such a robot is a mechanic, which is controlled through an electronic unit and servomechanisms. This solution can significantly reduce the cost of production of the box itself (up to two times compared to AT), as well as increase the reliability and maintainability of the unit.

In parallel, it is worth noting that the presence of the Tiptronic mode allows the driver to change gears in manual semi-automatic mode if necessary, use the full potential of the engine, overcome difficult sections on the road, etc.

Simply put, AMT includes:

- manual box;

- clutch and gear drives;

- friction clutch;

- sensors and ECU box;

Depending on the design, two types of clutch drives can be used (electric clutch drive from electric motors and hydraulic clutch drive with a set of hydraulic cylinders and solenoid valves).

In practice, a hydraulic drive works faster and more efficiently, but its cost is much higher. For this reason, this drive is usually used on sports cars and dual-clutch automatic transmissions (preselective gearbox).

An even lower gear shift speed on electrically driven transmissions leads to a disruption in the power flow and vehicle dynamics deteriorate. There are also complaints about the service life and reliability of single-disk AMT robots. Although it is based on a time-tested manual transmission that is controlled electronically, problems usually arise not with the transmission itself, but with the actuators, electronic components and clutch.

It is noteworthy that the service life of the servomechanisms is small (about 100 thousand km), while they are difficult to repair and require replacement. For many owners, the high cost of such devices is an extremely unpleasant surprise.