I hope that no one has lost reverse gear in an automatic transmission when a dump truck is moving in reverse towards you in a small alley. But this happened to me. Well, at least he was walking at a slow speed. I managed to run out of the car, and together we pushed my car back. But the transmission never started.

I started to figure out what was going on. And today I’ll tell you why the reverse gear of an automatic transmission stops working and how to fix the breakdown.

Design and principle of operation of reverse gear

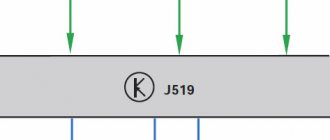

First, let's look at the principle of operation of reverse gear on an automatic transmission. Manufacturers have introduced a special lock into modern automatic transmissions. This is done by the brake band. Thanks to it, the driver does not feel sharp jolts from the machine when switching from the “Forward” mode to “Reverse” or moving backward.

Attention! Before you start moving the car back, press the brake pedal, wait until the car comes to a complete stop and only then move the selector lever to “R” mode and press the gas pedal. Moving the lever to the “Reverse” position when moving forward will damage the automatic transmission.

So what happens in the automatic transmission when the driver moves the selector lever to “R” mode.

- The driver stops the car and moves the selector lever to “Reverse”.

- The signal goes to the ECU.

- From the electronic control unit it is transmitted to the corresponding solenoid valves. They open up.

- The oil enters the torque converter, accelerates and, under pressure, presses on certain clutch packs that communicate with the gears.

- The brake band clamps the remaining friction discs.

- Reverse motion is set.

- The car is moving backwards.

Read

Full and partial oil change in Kia Sorento automatic transmission

If some part is faulty, then the transfer may not take place or the automatic transmission will switch to reverse gear thoughtfully.

What to do, how to behave

Actually, there are no complex algorithms, but there are a few things to remember:

- If you notice that “R” is on, do not accelerate

- Don’t switch to “D” right away, it’s fraught!

- You need to stop and after a complete stop, switch to “DRIVE”

Why do you need to do it this way, and not immediately transfer from “R” to “D”? WE have already realized that in modern cars, when such an error occurs, neutral is switched on, in which you can roll, but you should not turn on DRIVE from it

Causes of reverse gear malfunction

Almost always, the reverse gear stops shifting properly due to driver negligence. And only in extreme cases due to a manufacturer’s defect or design defect.

Reverse speed disappears due to incorrect control of the automatic transmission by a novice car enthusiast. The problem will be with the reverse speed due to insufficient oil filling or untimely replacement.

We will analyze the causes of the malfunction in the following paragraphs. But first, write in the comments: did your reverse gear break down? And how did you deal with this problem?

Electronic part

The lack of reverse gear in the automatic transmission can be caused by a breakdown in the electronic control unit. The wire is broken or the electric valve is stuck. The solenoid does not work most often due to contamination of the valve body with used oil.

The problem may be a faulty temperature sensor. The electronics will not allow you to switch to another gear when the machine heats up weakly. The vehicle will only move in first or second speed.

It happens that the tracks in the ECU, which are responsible for transmitting the signal to the corresponding solenoids, have burned out.

Automatic transmission oil level

I would like to ask, how often do you check the transmission fluid level in your automatic transmission? Did you know that due to lack of oil in the automatic transmission, sufficient pressure is not generated. This means that the components cannot work properly.

Read

What are automatic transmission clutches and how to replace them yourself

Last but not least, we can talk about the wear of metal parts, for which oil is a protective element. First of all, the lack of lubricant will affect the operation of the mechanism and, of course, the gear shift to reverse gear.

Release bearing wear

The reasons for the non-working reverse gear of the automatic transmission may be wear of the release bearing. Typically manifests itself as a knocking or noise when pressing the pedal.

Unlike previous problems that were related only to reverse gear, in this case other speeds may not be included. The machine will remain motionless or move forward with a grinding noise.

In addition to the release bearing, this category includes clutch fork failures.

Clutch fork

The reason why the reverse gear of the automatic transmission is not working may be a broken clutch fork. If the fork does not work, the clutch will not engage. This means that the car will not move.

And it can break at any time, even while driving on the highway, creating an emergency situation. Therefore, it is important to carry out annual maintenance of the vehicle’s automatic transmission.

Attention! Install only original parts. Low-quality or cheap fakes will make you pay twice.

Clutches

If there is no reverse gear on the automatic transmission, then the corresponding clutches may be worn out. In this case, the car should not pick up speed above 2nd gear. Slipping occurs when the box is warm. When cold there are no signs of problems.

Read

Which gearbox is better, automatic or manual: pros and cons

Pump

It will be difficult to solve the problem if the reverse gear of the automatic transmission does not work when the pump wheel is broken. In this case, the pressure in the entire machine drops. And, if the car moves forward and does not respond to pressing the accelerator, then the drum splines may be cut off.

You will have to pull the automatic transmission completely out of the car, disassemble and cut the torque converter. This is a labor-intensive and expensive procedure. At a service station, solving this problem can cost the car owner 11,000 rubles.

However, before you think that everything is bad, the reverse gear turns on blue, you need to check what really happened. In some cases, simply replacing the transmission fluid helps.

This procedure can be done by the driver himself or sent to a service center. The cost of replacing the lubricating fluid will cost the driver 2,500 rubles.

Tell us, what problems did you have with reverse gear?

Signs of problems with automatic transmission

Automatic transmission disassembled

It is no secret that during the operation of a vehicle, heavy loads are placed on the automatic transmission, which can cause gearbox failure. And although automobile manufacturers have recently been doing everything to increase the service life of these units, the automatic transmission is still considered one of the most vulnerable components. As for malfunctions and their symptoms, they can be very diverse. For example, if there is a malfunction in the valve body, shocks and jerks may occur during gear shifting. However, shocks can be very different, there are many types of them and they all indicate different breakdowns.

Especially if the breakdowns progress, the shocks and jerks may change. If such problems arise in the operation of the unit, the vehicle owner should troubleshoot as quickly as possible or contact specialists. It should also be noted that malfunctions of the automatic transmission can be expressed in the inability to switch one or another speed. Or in complete blocking of gears. If you are faced with a similar problem, then under no circumstances should you use your vehicle, otherwise the problem may worsen.

Sometimes automatic transmission malfunctions can be determined using regulators and other sensors with which the unit is equipped.

Such devices allow the motorist to identify and warn him about:

- insufficient level of transmission fluid in the system;

- insufficient pressure of the working lubricant;

- overheating of the automatic transmission;

- failures of other sensors;

- problems with switching modes.

Actually, the on-board computer can do the same thing by sending a message to the driver on the control panel by activating the Check Engine light. However, it should be noted that most of these reports of transmission failures are inaccurate. Accordingly, only complete computer diagnostics or disassembly and reassembly of the unit will allow you to accurately determine automatic transmission faults. It should also be noted that in some individual cases even diagnostics will not help, resulting in the need to dismantle the transmission.

Wear of the rocker bushing

Sometimes turning on reverse gear is accompanied by a lot of vibration and a characteristic crunch. The gear knob moves hard. In this case, the adjustment of the link, which connects the rod and the gear shift lever, may be disrupted. In addition, plastic bushings wear out quickly and must be replaced on time.

An experienced driver may notice excessive looseness and play in the lever. But if the wear occurs gradually, then it is difficult to notice the increasing free play. All repair work can be done directly from the salon. It is enough to remove the gear knob cover, remove the rocker and replace the bushing. After adjustment, the inclusions become clearer and softer.

The durability of a plastic part depends on the quality of the material used by the manufacturer. After adjusting the stroke of the rocker and replacing the bushing, this problem disappears. Sometimes craftsmen replace the factory mechanism with a shortened stroke. But they often forget that for it to work properly, it needs to be more accurately configured.

Electronics faults

Vehicles are equipped with different gearbox locking devices. Some vehicles use electromagnetic locking. In this case, the electrical wiring is located under the bottom of the car and is not protected by anything. In off-road conditions, the wires must be protected from damage, otherwise they will quickly become unusable. As a result, the supply of electricity to the interlock will stop and a problem will occur related to gear shifting.

Transmission traction is broken

Some cars are equipped with transmissions in which the shift rods are located outside the mechanism housing. In difficult climatic conditions (dirt, snow, icing), the free movement of traction is disrupted. This is especially noticeable when switching reverse gear, since it is rarely used. But in the morning it is necessary to leave the garage. To avoid such problems, in difficult conditions it is recommended to use a car that does not have external gear shift rods.

Note! Sometimes the length of the rod changes due to the loosening of the adjusting nuts, making shifting difficult. In this case, you will need to adjust and adjust the length, and the issue will be resolved.

There is not enough oil in the gearbox or its properties are reduced

If you do not take care of your car, a problem with engaging reverse gear may occur due to insufficient oil in the box or a deterioration in its performance properties. Inexperienced drivers believe that oil is poured into the gearbox all the time, and there is no need to change it. In reality, even high-quality lubricant with high mileage (about 100 thousand km) becomes unsuitable for use. These data correspond to a gentle driving mode.

But if the car is operated in difficult conditions associated with temperature changes, city traffic, and frequent switching, then the oil needs to be changed much more often. Over time, the properties of the lubricant change. Additives no longer work properly, harmful deposits, wear products, and dirt appear.

With dirty old oil, the gearbox mechanism works with difficulty not only when engaging reverse gear, but also other gears. It is necessary to pay attention to the presence of leaks under the car. If the lubricant leaks and its level is reduced, then the gearbox parts will wear out much faster than the period set by the factory.

Wear of release bearing, springs, gears, forks

Failure of the listed parts is accompanied by extraneous knocking or noise while driving, which is easy to hear. Reverse and other gears will be difficult to engage, or will become inaccessible altogether. To eliminate such malfunctions, you will need the help of specialists from a car repair shop. In this case, the gearbox will have to be removed from the car, so you should not start repairing this important unit yourself. This way you will save money and prevent further breakdowns.

Usually the fault is detected on the road: you stop at a traffic light, and when you try to shift into gear, difficulties arise. Cracks often appear on the shift fork, which even under light loads lead to the destruction of the entire part.

It happens that when starting off on loose snow or sand, the reverse gear switches off spontaneously. The handle has to be held forcibly.

The reasons may be the following:

- Displacement of the motor on the cushions and knocking out the speed.

- Worn synchronizer clutch or gear.

- The fastening of the link is loose and does not hold the fork in the desired position.

Note! The driver can independently tighten the engine mounts and secure the rocker. To do this, the car will need to be installed on a pit or overpass.

Problems with the valve body

Such malfunctions can occur in a number of cases. For example, improper operation of the gearbox. When the car enthusiast does not warm up the machine, but immediately starts driving. Symptoms: vibrations, shocks, impacts. In some cases, the car refuses to move. On modern cars, a malfunction with the GB is signaled on the on-board computer.

Torque converter problem

Such problems can only be resolved by repair. In general, such work is cheaper than work on the valve body and ECU. The symptoms are: knocking, rustling sounds, vibration, car dynamics suffer, when changing the oil in the box, there are copious amounts of chips in the pan.

What to do if the reverse gear of the automatic transmission on a Toyota Camry does not engage

The hardest thing is for drivers of Toyota Camry and other passenger cars that have low ground clearance. Knocks out the reverse gear at an extremely unpleasant time. For example, when you are stuck on a dirt, broken road and are trying to drive out backwards.

If there is no reverse speed on the Toyota Camry, then you should call a tow truck, which will help you not to be lost for a long time on village roads. If such an incident occurred in the city, then you can try to solve the problem yourself.

If the car moves normally in all gears, but when moving from the “P” mode to the “Reverse” position or, conversely, to the “Forward” position, then you may simply have a lack of transmission fluid. Place the machine on a level surface and check the oil level. It will show that the fluid is below the desired level. Add grease.

Read

Design and principle of operation of a hydromechanical gearbox

If neither forward nor reverse gear works, then the torque converter has failed. This problem can only be solved at specialized service stations. Therefore, you need to contact the service. If you have some knowledge in the field of automatic transmissions or your friend is an experienced mechanic, then you can remove and disassemble the automatic transmission yourself in the garage and cure the “donut”.

If only reverse gear does not engage, but the car drives normally, then the friction coating on the brake band has worn out. Tightening the bolts to adjust the tape will not help you either. You will need to buy a new brake band and replace it.

After you buy the brake band, don't forget to buy additional oil, an oil filter, and new gaskets for the pan and seals for the drain and fill plugs. Because the oil will need to be changed. Possibly the cause of problems with the brake band is dirty transmission fluid and a clogged filter.

Don't forget to check and clean the valve body. If the solenoid does not work, then be sure to replace the required valves with new ones. Since with the help of solenoids the valves in the automatic transmission are opened and closed. If the valve responsible for opening and closing the valve to create pressure for switching the reverse speed gears does not work, then the reverse will not be activated accordingly.

Attention! The filter device cannot be repaired or washed, only replaced.

Another problem for which you should contact a service center is driving only in first gear. None of the transmissions work anymore. This means that the drum splines have worn out. This problem may appear after long trips with dirty oil. The drive drum will need to be replaced without fail.

Read

Automatic transmission and trailer, or is it possible to haul a trailer with an automatic transmission?

The last described problem can also appear on cars that often change the oil and take care of them, but the cars are from the 90s and 2000s. Wear and tear occurs as a result of aging.

Signs of aging of the automatic transmission can be wear of the friction discs. Of course, they can be destroyed by dirty oil, sudden and cold starts. But, if a car enthusiast prefers a quiet ride and warms up the automatic transmission in severe frosts, then wear of the clutches can only happen due to the aging of the car.

In any case, it is necessary to undergo preventive maintenance at a service station once a year. This regular procedure will help avoid many problems that arise with Toyota Camry and other cars.

Tell me, how often do you undergo maintenance at the service center? Have you contacted a service station because the reverse gear is not working or did you find and fix the problem yourself? Write your answers in the comments.

Troubleshooting methods

We looked at the causes and signs of machine malfunctions. Now it’s worth saying a few words about repairs. Let’s say right away that there are two methods for solving transmission problems:

- Self-repair or prevention.

- Contacting specialists.

Needless to say, the first option is cheaper and preferable for every car enthusiast. However, in reality, not all operational problems can be solved with your own hands. For example, if the automatic transmission does not change gears or slips, then only a qualified specialist will assist the car.

Independent solution

We present a number of correctable errors in the appropriate form: general cause – possible problems – ways to eliminate them.

1. Misalignment or malfunction of the gear shift component:

- the car moves in gearbox mode P;

- The speed letter on the panel does not match the set one.

Remedy: Diagnosis and replacement of the faulty part; you can repair it yourself according to the instructions provided.

We recommend: Design and principle of operation of an internal combustion engine

2. Oil leakage from the automatic transmission. Common problem with the box:

- the fastenings of the mechanisms inside the transmission come off on their own;

- destruction or unsuitability of oil seals and gaskets.

DIY repair methods:

- tightening bolts, purchasing and installing new seal rings;

- lowering the oil level in the automatic transmission.

3. Noise or uncharacteristic sounds when the box is operating:

- the car changes gears itself;

- switching positions occurs with great difficulty;

- The car does not respond to switching and does not move.

Remedy: Measure the oil level and add the required amount.

Only the main cases of minor breakdowns inside the automatic transmission are given. If your situation fits at least one of the points, read the instructions for the car. Inside you will find step-by-step steps to solve the problem. In the future, it is recommended to turn to professionals.

Repair in service

We will describe the problems that require contacting a qualified workshop.

1. The car remains in place during any action with the gearbox mechanism. There is no reaction or the slightest movement.

Causes:

- little oil in the system;

- valves or rings are clogged;

- hydraulic system malfunction;

- filter failure;

- Main gear malfunction or wear.

2. Shocks and impacts when changing gears.

Causes:

- coupling wear;

- hydraulic unit valve malfunction;

- Valve spring damage.

3. Unhealthy noise in the differential area of the car

Causes:

- bearing or gear wear;

- some mechanisms jam or become loose.

Many problems are more often identified at the stage of disassembling the transmission. Thus, a trip to the service center is a priority for a working car.