Vehicle design VAZ 2109

Speaking about the VAZ-2109 vehicle, it should be recognized that it would be more correct to use the term “VAZ-2108 brake system”. It was on the G8 that the scheme of the specified vehicle was implemented.

The components, parts and assemblies of the “nine” were modified and optimized, but the vehicle was not fundamentally different from the braking system of Russian rear-wheel drive cars. Its main design feature is the diagonal separation of the brake circuits, which significantly increases the level of safe operation. The hydraulic drive circuit is responsible for the operation of the front right and rear left brake mechanisms, and the brake circuit is responsible for the operation of the rear right and front left ones.

A peculiar division of “areas of responsibility” made it possible to ensure fairly effective braking of the vehicle in the event of a malfunction of one of the circuits. By redistributing functions between circuits, the risk of negative consequences arising from the failure of one of the vehicle elements is compensated.

The fundamental principle of the brake functioning scheme is the action of friction mechanisms (using the friction principle). The vast majority of “nines” were equipped with two types of brake mechanisms: disc (front) and drum (rear).

Main elements of the system

The vehicle's vehicle includes many auxiliary parts, but the main design element is the TC, which creates pressure in the pipes. This element is made of a piston moving along a perfectly flat surface. Rubber rings are used to seal connections between components.

The structure of the vehicle includes two more main elements: a mechanism that directly brakes the rotation of the wheel, and a drive that transmits the converted braking force from the driver to the brake mechanism. The hydraulic drive of the “nine” vehicle differs little from the element installed in most classic models of the Volzhsky Automobile Plant.

Main elements of the system:

- GTZ - master brake cylinder;

- vacuum booster;

- pedals;

- expansion tank equipped with a working fluid level sensor;

- front and rear mechanisms;

- pressure regulator with lever and elastic drive lever;

- pipelines of two separate circuits;

- front and rear wheel flexible hose system;

- brake fluid.

The parking brake (handbrake), installed on the “nine”, has a cable drive and is based on braking the rear wheel drums with shoes by moving them apart.

Brake system diagram

The VAZ 2109 brake system diagram does not have complex parts, which simplifies repairs and makes this car ideal for novice motorists.

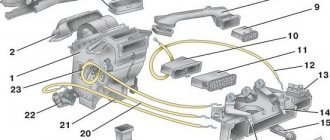

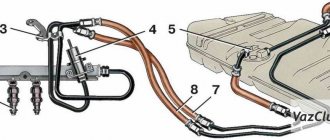

Components of the working vehicle of VAZ 2108, 2109, 21099 vehicles.

- Front left wheel mechanism (caliper).

- Hose.

- A tube.

- GTZ

- Front right wheel mechanism (caliper).

- Hose.

- A tube.

- GTZ tank.

- Vacuum amplifier (VA).

- Pedal.

- A tube.

- Hose.

- Rear right wheel mechanism.

- Fluid pressure regulator (PR) in the rear wheel mechanisms.

- RD lever.

- Rear left wheel mechanism.

- Hose.

- A tube.

HOW TO REPLACE THE BRAKE PRESSURE REGULATOR

The distribution of the load, in other words, across the brake cylinders of the brake fluid, when turning, is carried out by the VAZ 2109 brake pressure regulator. The appearance of body skids during braking may indicate a malfunction of the regulator, if the remaining components are in working condition:

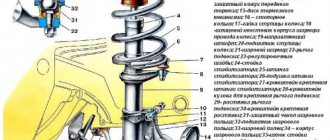

- The elastic lever must be disconnected from the rear suspension beam. For this purpose, the locking ring is removed, then the finger and earring are removed.

- All brake pipes are disconnected from the regulator using a special wrench. After disconnection, all tubes must be marked. This will make the work easier when assembling the unit. To prevent oil leakage, all holes are plugged.

- The bracket is removed from the studs on the body along with the regulator.

- The regulator is disconnected from the bracket and a new one is installed in its place.

- Assembly is performed in reverse order.

Periodic maintenance and timely repair of all components of the brake system will ensure the reliability and safety of the VAZ 2109 car. You can watch the video on how to properly carry out repair work.

Sources

- masteravaza.ru/tormoza/remont-tormozov-tormoza/vaz-2109-remont-tormozov-392

- znanieavto.ru/stop/tormoznaya-sistema-vaz-2109.html

- drive2.ru/l/4899916394579103916/

- twokarburators.ru/shema-rabochey-tormoznoy-sistemy-2108-2109/

- ladaautos.ru/vaz-2109/sxema-prokachka-i-remont-tormoznoj-sistemy-vaz-2109.html

Frequent breakdowns

In the “nine”, each of the vehicle malfunctions can lead to irreparable consequences that threaten human life.

Main problems:

- The brake pedal does not work. When you press it, the load is slightly increased. Even if the driver does not press the pedal hard, the braking becomes too noticeable. In this case, the car moves “in a jump-like manner”: at first it goes quickly forward, and then returns back.

- The car skids to the side. Sometimes when braking, the car behaves differently than usual. He either drifts to the side, or quickly leans forward. There is a solution to this problem. It is required to carry out a complete diagnosis of the car at a car dealership.

- Long braking distance. In this case, when you press the brake pedal, it may not occur.

- The wheels do not brake at the same time. This case is quite rare. The braking distance increases several times, and the car begins to wobble.

- The vacuum booster has failed. The main sign that tells the driver about the failure of this element is difficult pedal movement. This is fraught with poor braking, which can lead to an accident in an emergency. On the “nine”, replacing the vacuum booster must be carried out. This can be done either at a service station or in your personal garage with your own hands.

Repair of breakdowns in vehicles

To avoid emergency situations on the road, it is necessary to monitor the vehicle and carry out diagnostics in a timely manner. If damage is detected, carry out repairs.

Malfunctions in the vehicle and ways to eliminate them on VAZ 2108, 2109 and 21099 vehicles.

| Increased brake pedal travel | |

| Liquid leak from cylinders | Replace failed cylinder parts, wash and dry pads, discs and drums, and also carry out preventative maintenance on the hydraulic drive system |

| Air in the vehicle | Remove air from the system |

| The rubber sealing rings in the GTZ are damaged | Replace the rings and bleed the system |

| Damaged rubber hydraulic hoses | Replace elements and bleed the system |

| Increased runout of the brake disc (more than 0.15 mm) | Sand the disc. If its thickness is less than 10.8 mm, it will need replacement |

| Fluid leakage through the sealing rings of the RD pusher | Replace O-rings |

| Insufficient braking performance | |

| Oiling of linings on mechanism blocks | Clean the linings with a wire brush using warm water and detergent. Eliminate the cause of liquid or grease getting on the pads |

| Jamming of pistons in cylinders | Remove the causes of jamming, replace damaged parts and bleed the system |

| Complete wear of linings and pads | Replace pads |

| Overheating of mechanisms | Stop immediately and allow the machinery to cool down. |

| Using pads with mismatched linings | Use pads only recommended by the manufacturer |

| Incorrect RD adjustment | Adjust the RD drive |

| Loss of tightness of one of the circuits (accompanied by partial failure of the pedal) | Replace damaged parts, bleed the system |

| Incomplete release of all wheels | |

| There is no free play of the pedal | Adjust pedal free play |

| The protrusion of the adjusting bolt of the vacuum booster rod relative to the mounting plane of the master cylinder is impaired | Adjust the protrusion (1.25-0.2 mm) of the adjusting bolt |

| Swelling of the rubber seals of the master cylinder due to gasoline, mineral oils, etc. entering the liquid. | Thoroughly flush the entire system with brake fluid, replace rubber parts |

| Master cylinder piston jamming | Check and replace the master cylinder if necessary |

| Braking one wheel when the brake pedal is released | |

| Rear brake pad tension spring is broken or weakened | Replace spring |

| Sticking of the piston in the cylinder due to contamination or corrosion of the cylinder body | Disassemble the cylinder, clean and wash parts, replace damaged ones |

| Swelling of the cylinder sealing rings due to gasoline, mineral oils, etc. getting into the liquid. | Replace the rings, flush the hydraulic drive system with brake fluid |

| Violation of the position of the caliper relative to the disc when loosening the bolts securing the pad guide to the steering knuckle | Tighten the fastening bolts, replace damaged parts if necessary |

| Incorrect adjustment of the parked vehicle | Adjust the parking brake system |

| The car skidding or pulling to the side when braking | |

| Cylinder piston jamming | Check and eliminate jamming of the piston in the cylinder, if necessary, replace damaged parts, bleed the system |

| Blockage of any steel tube due to dent or blockage | Replace the tube or clean it and bleed the system |

| Contamination or oiling of discs, drums and linings | Clean mechanism parts |

| Incorrect adjustment of the RD drive | Adjust drive |

| RD faulty | Repair or replace the regulator |

| Wheel alignment angles are incorrect | Adjust wheel alignment angles |

| Different tire pressures | Set normal pressure |

| One of the vehicle circuits does not work (accompanied by deterioration in braking efficiency and increased pedal travel) | Replace damaged parts |

Necessary materials

If you decide to install the HTD yourself, then you will need the following materials:

- Directly disc brakes, machined under the hub by 0.6 cm. The diameter of the disk should be 24 cm. Please note that it is not necessary to grind the disk itself. If you want to leave it unchanged, then you need to groove the hub.

- Front calipers and hoses.

- Faceplates necessary for attaching calipers. You will have to tinker with this part, since it is quite unusual and requires separate manufacturing to the exact dimensions.

- High quality pads that fit true to size.

- 12 bolts M10 × 1.25 with groovers.

- 8 spacers. You can use timing belt tensioner roller washers for the VAZ-2108.

When you have acquired all the necessary materials, it’s time to proceed directly to the replacement. The procedure is performed in several stages.

Rules for operating vehicles in the nine

When operating the “nine”, it is necessary to strictly observe the scheduled maintenance periods not only for the engine, but also for the vehicle, and also to carry out repairs of the master brake cylinder (MBC) of the VAZ 2109. This applies to the friction linings of the front disc and rear drum brakes. Complete wear of the friction linings threatens unexpected vehicle failure in an extreme situation.

Periodically it is necessary to check the condition of the linings, monitor their level of wear and replace if necessary. It is necessary to carefully monitor the brakes of the VAZ 2109 in terms of fluid leakage through worn gaskets and seals.

Excessive wear of sealing elements is accompanied by:

- the risk of insufficient effort in the shopping center;

- pedal failure when driving;

- increasing braking distance.

All of the above creates very serious risks. A vehicle is one of the critical systems for ensuring the safety of the driver, passengers and other road users.

Requirements for the brake system during technical inspection

In order to more accurately determine the real technical condition of the car before instrumental control, it is best to undergo diagnostics at a special station. This will allow you to determine the technical condition of the car and the need to repair a particular unit.

During technical inspection, the operation of all wheels is especially carefully monitored for deceleration (specific braking force is not less than 64%) and the unevenness of their operation (the spread between the wheels of one axle is not more than 9%). The control is carried out on the running drums, so the vehicle must be carefully adjusted before inspection. The parking brake must hold the vehicle on a slope of at least 23%, without taking into account uneven action on the wheels of the rear axle.

Experienced specialists say that there is no need to immediately repair the vehicle at a service station, since the pads should break in (within 250-300 km). If the force remains uneven, you should try rubbing the disc a little with sandpaper to remove large nicks from it. The regulator must be adjusted so that it correctly redistributes the braking force between the front and rear axles of the car depending on the load.

It should be taken into account that uneven braking is affected by the difference in tire pressure. Wheel elements should not be overinflated, as this also reduces the effectiveness of the brakes. GOST also retains the possibility of visual inspection of the vehicle by an inspector. During the procedure, the car must brake to a complete stop with 100% blocking of all wheels without losing the straight trajectory.

Differences between vehicles of other VAZ models

VAZ Classic cars (models 2101 to 2107) were equipped with a traditional hydraulic drive. In this system, the force required to operate the mechanisms installed on the wheels is created using the GTZ when the driver presses the pedal. The increased pressure from the master cylinder is transmitted through the lines to the wheel cylinders, which move (in disc brakes) or spread apart (in drum brakes) the pads.

The wheels of VAZ-2101 – 2107 vehicles are equipped with two types of brake mechanisms:

- modern disc wheels - on the front wheels;

- classic drum ones - on the rear wheels.

Both of these mechanisms are frictional, based on the friction force between moving and stationary parts. The difference between disk and drum mechanisms lies in the position and form of interaction of these parts.

The VAZ 2114 and 2115 use a working vehicle of the VAZ 2110 family with diagonal separation of contours, which ensures high active safety of the vehicle. One hydraulic drive circuit ensures the operation of the right front and left rear mechanisms, the other - the left front and right rear.

If one of the circuits of the working vehicle fails, the second circuit is used, ensuring that VAZ 2110, 2111, 2112 vehicles are stopped with sufficient efficiency. The hydraulic drive includes a hydraulic drive (indicated in the figure as number 6) and a dual-circuit regulator (number 9) of the rear brake pressure. The parking vehicle is driven by the brake mechanisms of the rear wheels.

- Front wheel mechanism.

- Pipeline of the “left front-right rear” circuit.

- Main cylinder.

- Pipeline of the “right front-left rear” circuit.

- Master cylinder reservoir.

- VU - vacuum amplifier.

- Rear wheel mechanism.

- Elastic pressure regulator drive lever.

- RD - pressure regulator.

- Pressure regulator drive lever.

- Pedal.

- A - flexible hose of the front brake.

- B — flexible rear brake hose.

Stage 1. Removal of the PTA

First of all, you need to remove the wheel. After this, you need to loosen the handbrake cable and bring the pads together. The guide pins are unscrewed using a 12mm wrench.

If the car is old or the brakes have not been changed for a long time, it is recommended to treat the seats with a wire brush, and also lubricate all running surfaces with WD40. This will help you remove the brake drum without much effort.

Please note that even if the drum is tight, you need to remove it gradually, gently tapping it with a hammer along the entire circumference. If you do not want to damage the part, then use a hammer with a rubber tip or a rubber gasket.

Next, remove the tension spring and guides by prying them off with a screwdriver. After this, the brake pad needs to be lifted up, the spacer bar removed and the pad and tension spring removed.

To remove the second block, you need to remove the handbrake lever from the cable. The bolts that secure the hub to the beam should be treated with WD 40 and unscrewed with a split or regular 17 wrench.

At the last stage, the brake tube of the hub is dismantled. After this, you can begin installing the HCD.