What ball joints are in the field?

Three generations. They differ from each other in body geometry

- until 2009, a “kopek” knot was used. At the same time, there were identical parts on top and bottom. Art. – 2101-290419;

- 2009-2016 the element was unified with the model created jointly with GM. Art. – 2123-2904192. Suitable for 1st generation;

- 2016 – present, the data allows us to obtain the original wheel running distance. Interchangeability with other generations is excluded. Art. – 21214-2904082.

Do-it-yourself ball replacement

To diagnose a malfunctioning ball joint, you should rely on the following symptoms:

- knocking noise when driving on rough roads;

- when you turn the steering wheel you hear a creaking sound;

- the car drives unstably along a straight path;

- tires wear unevenly.

If the above points match your case, then you need to replace the ball joints.

About the causes of the malfunction:

- low quality parts (most often);

- lack of lubrication under the boot or rupture of the boot;

- natural wear and tear;

- Frequent off-road driving.

Replacing the lower support

To remove the Niva 2121 ball joint, lift the car on a jack and remove the wheel, clean all elements from dirt using a wire brush or compressed air, unscrew the hub adjusting nut (with the cap installed, use a chisel).

Using a 22 mm spanner, unscrew the nut securing the assembly to the steering knuckle (KC).

Place a stop at the lower point of the suspension arm (screw jack, bottle jack, block of wood).

Release the ball mount from the lower arm using two 13 mm wrenches.

Move the PC away from the lever.

Using a puller, press out the ball joint pin.

If you don’t have a special device at hand, insert a block into the space between the upper suspension arm and the rebound buffer bracket, after compressing the spring using a block or jack and tightening the support pin nut. Then hit the PC eyelet with concentrated blows until you get the result.

Before installing new supports, do not forget to fill it with ShRB-4 lubricant.

Ball joint malfunctions

The condition of the front suspension parts affects the comfort and safety of the ride. The body and pin of the products are made of durable steel, so the plastic inserts are subject to wear. Play in the hinge joints impairs directional stability and, during prolonged use, causes destruction of the ball joint housing.

In this case, the finger will jump out of the seat and the wheel will be “turned out”. Such a breakdown threatens a serious accident. Therefore, you need to monitor the condition of the suspension and change the ball joints in time (their design does not provide for the possibility of repair).

Signs of malfunction:

- Knock in the front suspension when overcoming speed bumps, bumps and holes.

- Front wheel play, which can be noticed while driving or after jacking up the car.

- Creaking sound in the suspension when turning the steering wheel.

- Uneven tread wear.

The listed “symptoms” may also appear with other suspension malfunctions. Therefore, the decision to replace ball joints must be made after checking their condition.

The housing of some hinges is equipped with a diagnostic hole to determine the degree of wear.

However, for most models, two other ways to check the condition are relevant. And both require a partner.

- Rock the car while parked. During this lateral and vertical swing, no knocking should be heard from the hinges.

- Raise the car with a jack and rock the wheel while holding the brake pedal. This is a more accurate way. Compressed brake pads eliminate play in the wheel bearing, so knocking occurs only when there is play between the pin and the ball joint spacers.

mouse balls

An IBM field service memo details the procedure for replacing mouse balls.

Example:

[Collected via email, 2002]

MEMO

Re: Replacing mouse balls.

If your mouse doesn't work or doesn't work properly, it may need a ball replacement. Mouse balls are now available as FRUs (Field Replacement Units). Due to the delicate nature of this procedure, mouse ball replacement should only be performed by trained personnel.

Before proceeding, determine the type of mouse balls by examining the bottom of the mouse. The inside balls will be larger and more complex than the outside balls. Procedures for removing beads vary depending on the mouse manufacturer. Foreign balls can be replaced using the pop off method. The inner balls are replaced using the twist-off method. Mouse balls are generally not sensitive to static electricity. However, excessive handling may cause sudden discharge. Once the ball replacement is completed, the mouse can be used immediately.

It is recommended that each person have a couple of spare balls to maintain optimal customer satisfaction. Any customer who is missing eggs should contact local staff who are responsible for removing and replacing these required items.

Keep in mind that a customer without properly functioning balls is a unhappy customer.

gets this in her inbox more than once, which certainly results in a loud knock in the long beard category.

Was this a real memo? "Real" in the sense that someone at IBM actually wrote it and may have distributed it to field service people, but it was always intended as a professional joke; this was not a "serious" note that some hapless executive inadvertently called a fun tour with dual intentions.

The note remained remarkably unchanged over the years. As the piece was passed from hand to hand via cyberspace, some changes were made to the text (“Please be aware that a customer without properly functioning balls is a unhappy customer.” Singer was not in the original, and today “Any customer who has lost eggs, should contact local personnel responsible for removing and replacing these necessary functional items" used to read "Any customer whose balls are missing should suspect local personnel of removing these necessary functional items"), but for the most part ends up in the postal boxes are now pretty close to what was distributed more than ten years ago.

Barbara "Keys to Big Blue" Mikkelson

Signs of malfunctions and how to check

Knock from the wheel - a characteristic clang is clearly audible while driving . It does not disappear even at low speeds. Intensifies when hitting an obstacle. The symptom may appear only once or be systematic during increased loads on the ball joint. Exceptions include severe frost - in this case, the lubricant in the CV joint may freeze, as a result of which the support heats up during the start of movement, which creates a knock.

If the ball joint is damaged and the wheel alignment characteristics have changed, then the main symptom will be rapid wear of the rubber in the lower part of the wheel. Play in the ball joint causes the wheel to begin to loosen. This leads to the loss of the ability to keep the road straight. Deviations from the norm will increase along with speed.

Important! The wobble of the car is difficult to notice if in most cases the Niva Chevrolet is used for off-road driving.

Creaking when turning is a sign of damage to the power steering or steering rack . To accurately determine the source of the sound, it is recommended to undergo diagnostics. Uneven tire wear is visible upon visual inspection. When it's time to replace the ball joint, severe wear will be noted along the inside edge of the tread.

If the vehicle's trajectory changes during braking , then a sideways movement (to the damaged side) may indicate a problem with the ball joint. This is accompanied by clicking or tapping.

Tips for extending the life of ball joints and further operation

The main culprit for the rapid failure of ball joints is a weak seal. The rubber used on the boot weakly resists external factors and quickly breaks, after which dirt and water get into the joint and the ball joint begins to knock. If you buy cheap ball joints, then in any case you will have to buy good boots separately. Polyurethane anthers perform well in terms of resistance to aggressive environments.

- The second point: increased wear on ball joints. The car's suspension is structurally from the 60s. The size of the ball joints is too small to carry even average loads, not to mention constant use on poor country roads. When choosing expensive manufacturers, you can be confident in the quality of the parts, but I recommend checking for the presence of lubricant under the anthers, since in many cases there is none there at all.

Also interesting: How to bleed the brakes of a Niva Chevrolet

The service life of ball joints on a Chevrolet Niva is too ambiguous. Depending on the manufacturer and where the car is operated, ball joints can last from 5 to 50,000 kilometers.

After replacing the ball joints, you should take the car to have the wheel alignment checked.

https://www.youtube.com/watch?v=8fADPdcouec

If you have any problems with dismantling and installation work, then there are many videos on the Internet on how to get out of this or that situation. A common situation is turning the pin together with the nut when removing the ball joint.

Read news about the new Niva

- The best ball joints for a car

- UAZ or Niva - which is better, car characteristics and features ::

- Tire size for the field, all-season tires for the field 4×4, mud tires, the best winter tires for r16 wheels

- Tires for Niva Chevrolet. Which one to choose?

- TOP 10 best brake pads for VAZ and Lada (Front, rear)

- Which battery is better for Niva

- Shock absorbers for Chevy Niva rating

- Tire size for the field, all-season tires for the field 4×4, mud tires, the best winter tires for r16 wheels

Step-by-step instructions: how to replace the lower elements of the assembly

If you need to replace the lower ball, then the sequence of actions is as follows:

To install new parts, perform all steps in reverse order . After this stage, the ball joints on the Chevrolet Niva will be repaired. Additionally, it is recommended to adjust the wheel alignment angles. For this purpose, it is worth contacting specialists in the workshop, since setting errors are eliminated there.

We change and install ball joints on a Chevrolet Niva

In addition to the engine, the car contains a large number of additional components that greatly affect the comfort and quality of movement. For most passenger cars and SUVs, these components include the car suspension. Its important component is the ball joint. Many people have heard about such a part, but in practice they do not encounter it until the need to replace it arises. Where it is located and what purpose it serves will be discussed in more detail in this article.

The Chevrolet Niva ball joint is installed in the front part of the car and serves to ensure interaction between the control lever and the wheel hub. This is necessary to transmit a control signal to the wheels.

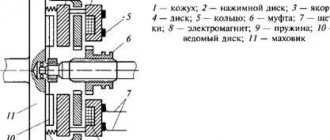

The part is an independent element that consists of two parts. One is made in the form of a finger, the end of which is threaded. The other is spherical, the end of which is enclosed in the body of the part. Inside it is filled with a special lubricant based on polymer materials. The steel pin can move freely to provide the required functionality. To provide protection from dust, the design includes a special rubber boot. This is the most vulnerable part of the entire structure, which becomes unusable over time. As a result, the polymer lubricant becomes saturated with dust and dirt, increased friction occurs, and as a result, a knock appears in this unit.

Checking the product.

Before replacing ball joints on a Chevrolet Niva, you need to inspect their appearance for damage. Typically, such an assessment is carried out by specialists at a service station. But this cannot always guarantee a good result; in addition, this method is quite expensive. When inspecting yourself, you must first of all pay attention to the main signs of malfunctions:

- Large gap gap

- Damage to the surface of the boot

If only the boot is out of order, and the wear is not so strong that there is a backlash, then you can only get by by replacing it. If the problem is more serious, then the owner is faced with the question of choosing a high-quality and inexpensive part. The most common options on the market are products from Kedr, Phobos and Trek. Usually the cost of the sets is the same and does not exceed 3,000 rubles.