Antifreeze goes into the engine - what to do?

If you begin to notice that the antifreeze level is constantly falling, you should check the entire technical condition of the car. Most often, the cause of this phenomenon is a worn cylinder head. If you do not start solving the problem in a timely manner, the temperature of the power unit increases significantly. This will cause the metal to expand and the pistons to wedge. To solve the problem, you need to replace the gasket or the cylinder block itself. Typically, a leak in this part can be recognized by the following signs:

- A sharp increase in oil consumption.

- Emission of thick white smoke from the exhaust pipe.

- Change in the consistency of the engine oil, the appearance of bubbles in it.

Antifreeze getting into oil is quite dangerous. Due to the mixing of liquids, the oil begins to lose its physical properties. It becomes thicker and more viscous. Because of this, all internal channels become clogged, which negatively affects the heat exchange of the power unit. This may lead to the following problems in the future:

- Rapid consumption of antifreeze.

- Rapid wear of the main and connecting rod bearings of the crankshaft.

- Excessive piston wear.

- Overheating of the power unit.

VAZ 2114 brakes poorly and weakly

The car brakes poorly.

At speed you have to press the brakes with all your might. The car brakes very lazily, smoothly, and not sharply, as it should be when you press the brake hard. The vacuum cleaner is working. The brakes are normal. The brake discs are good. Where to look? Is there a difference between pressing when the engine is off and when the engine is running? Pump it 5 times and press and start the engine the pedal should go away a little, which means the vacuum is pumping

0 0 Answer rating: 0

Alexey, yes, I did that, the pedal fails, the vacuum cleaner works

0 0 Answer rating: 0

Alexey, urgently check that all the wheels are skidding. Maybe the butt is completely silent

0 0 Answer rating: 0

Alexey, what is use? type check if all wheels are braking? But as?

0 0 Answer rating: 0

Alexey, at least on dusty asphalt, brake to the floor and see if there are tracks left by all the wheels or not.

0 0 Answer rating: 0

Alexey, I'll try. And if it turns out that everyone is slowing down, then where to dig further? What other reasons could there be? When I brake, the car brakes evenly, the steering wheel does not move.

0 0 Answer rating: 0 0 0 Answer rating: 0

Alexey, I also thought about this. Does it make sense to pump them up?

0 0 Answer rating: 0

Bleed the brakes. The rear cylinder may still be leaking.

0 0 Answer rating: 0

Pump the brakes or check the cylinders

0 0 Answer rating: 0

pump air there. start from the farthest one, I pump up the rear left-right, then the front right-left. (And for those wise guys who say that this is not correct cross to cross and something like that, it’s your decision) another important point needs to be pumped in the pit and not by jacking it up (for those who say that this is nonsense, go to hell...) because there is a type of load sensor there, I don’t know what it’s called according to the textbook

0 0 Answer rating: 0

Source

Car cooling system

The cooling system plays an important role in engine operation. Daily use of the car and intense loads lead to heating of the engine and the entire engine compartment, especially in the summer. The coolant, passing through the complex components of the power unit, maintains the engine temperature at an acceptable level (80–100 oC), preventing overheating. It is important to remember that the cooling system is completely sealed and the coolant level should not change from the moment it is filled until it is replaced.

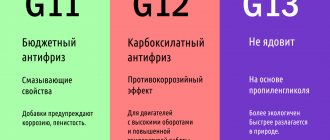

Antifreeze is used as a coolant, i.e. a non-freezing liquid, which is important in the winter season. This liquid is often called antifreeze. Antifreeze is the international name for car coolant. Antifreeze is also antifreeze, only domestically produced.

There is no air in the system, so it is important to keep all connections tight

During engine operation, the liquid constantly circulates through the system in a circular sequence, passing through the components of the unit. When the engine heats up, the liquid molecules expand and its volume in the system increases. In order to avoid rupture of elements in the cooling system, an expansion tank is provided. All excess liquid when heated is sent to the tank, and when cooled it is returned back to the system.

Where can the coolant go from the expansion tank?

A constant decrease in fluid in the expansion tank is a serious signal for the driver. A complete check of the entire cooling system and leak detection is the very first stage of diagnosis. It's not so bad if it's just a leak. It is much more serious when the liquid leaves, but there are no drops or smudges anywhere. In this case, serious problems with the engine may occur, the elimination of which will be very expensive for the car owner.

Leak in the system

Antifreeze goes away for various reasons. The first thing to consider is the leak in the system itself. The following may leak:

- engine radiator;

- stove radiator;

- connecting hoses;

- pump and thermostat;

- expansion tank cap or the tank itself.

You can eliminate smudges with your own hands, in a garage. If there is no opportunity to do this or there is not enough experience, then it is better to entrust the work to professionals and take the car to a car service center.

Antifreeze is leaking - it's time to carefully examine the car's cooling system

Radiator is leaking

Radiator leaks can be determined by visual inspection. If there are leaks on the radiator body and drops underneath it, you must immediately find the source of the leak. It is necessary to examine the connection points of the pipes, because if the fastening clamps are loose, then liquid can leak out in the connecting parts.

The factory clamps that hold the hose to the radiator do not have thread tension, so they need to be replaced. If there are no such clamps, then you can purchase a regular clamp for a screwdriver and tighten it thoroughly.

A leak in the radiator itself can occur as a result of mechanical damage or wear. The only way to temporarily solve the problem is by soldering. It is worth noting that a sealed radiator will not last very long and may leak again at any time, so replacement is recommended.

The radiator can leak in the area of the plastic and radiator grille. In any case, it is recommended to replace it with a new one

Furnace radiator leaking

This malfunction may not be detected immediately, since the heater is located in the cabin. Initial signs of a radiator leak may include:

- sweetish smell of antifreeze in the cabin;

- fogging of the windshield with an oily coating;

- drops on the carpet under the dashboard.

The stove is located in the passenger compartment and is almost identical on all cars

If these signs are present, then you need to provide access to the heater by removing the plastic decorative protection and inspecting the part for damage. We make a decision: repair or replacement.

Leaking connecting hoses and pipes

Wear of hoses occurs due to deformation of the material due to temperature changes. When heated, the hoses expand and when they cool, they contract. Over time, cracks appear in the hoses, even minor ones. Ignoring this defect can lead to a ruptured hose and other disastrous consequences. The clear solution is to replace leaky hoses.

Almost the entire cooling system consists of rubber connecting hoses. It is important to constantly monitor and correct faults in a timely manner

A little about the problem

The expansion tank is an integral component of the internal combustion engine cooling system. The main task of this element is to dampen pressure fluctuations inside pipelines that arise as a result of a decrease or increase in the volume of cooling liquid when it is cooled and heated, respectively.

Such a capacity allows you to reduce mechanical loads on the entire cooling system. Thus, the internal combustion engine is protected from water hammer and air locks. Although they cannot be completely prevented, as a result, sometimes you have to figure out how to remove the airlock. Essentially, the tank replenishes the liquid deficit in the cooling lines and acts as a receiving tank when excess coolant appears, which occurs when the composition is heated. Structurally, it is a seemingly ordinary sealed plastic tank.

An integral element of the unit is the expansion tank cap, which also serves as a valve. With its help, pressure enters the tank from the outside when there is a deficiency in the system, or excess pressure is released.

When the coolant heats up, the liquid gradually expands, thereby filling the tank space. In parallel with the increase in evaporation from heating, the internal pressure increases. For various tank designs and specific car engines, along with their cooling system, certain threshold pressure values are provided. When they are reached, a valve begins to operate, which expels excess pressure from the system. But there are situations when the antifreeze is already boiling, the pressure increases, but it does not release. Instead, it throws out the liquid itself. That is, the valve does not cope with its tasks. Why this happens and how to deal with it is the key question of this material.

Moreover, emissions can appear after the engine is stopped and during operation of the power plant. Let's understand the reasons.

Signs

There is a quick method to determine external leakage without the help of specialists. A faulty expansion tank, radiator hoses - all these parts are easy to find in the event of a breakdown. The hoses are checked by touch, and if the faulty hose is bent, the antifreeze will simply flow out of it like a fountain. After the hoses, their connections are checked, which can lead to a similar result.

One of the reasons why antifreeze leaves the system may be damage to hoses or tubes, as well as deterioration of the fasteners at the junction of the radiator with the circulation pipes.

Damage to the cooling system tubes will result in fluid leakage. How to check whether the tubes remain intact in the event of a leak? To check whether this is so, you should place a piece of cardboard under the car and check it after some time. If there are stains on it, then the problem is in the tubes and fasteners. In this case, only their repair can help.

We recommend: How to replace the cabin filter of a UAZ Patriot with your own hands?

Where does antifreeze go if the radiator malfunctions? If the front window of the car fogs up, the carpet under the front seat gets wet, or condensation occurs, then the cause is a faulty radiator. Getting to it from the salon can be difficult, so you can check its functionality in another way. We need to connect the inlet and outlet hoses, and when there is no leakage during the circulation of the refrigerant, the antifreeze leaves precisely from the part we are identifying.

Why does antifreeze leak if there is an internal leak? Most likely, it enters the engine system and mixes with the fluids present in it, very often oil. If the exhaust gases have a sweetish smell, and the smoke coming out of the pipe is bright white, then you should check the type and level of oil in the car.

Antifreeze in the engine creates deposits on the dipstick. In the same way, spark plugs are checked, which turn white when there is antifreeze in the engine. It is difficult to repair such a breakdown yourself, so it is better to contact a service station.

If the timing belt guard is dirty, there is likely antifreeze residue on it. To diagnose the problem, you need to remove the timing belt cover. When the cover is removed, you can determine the cause visually; the maintenance problem may be in the pump. This part cannot be repaired; most likely, you will have to buy a new pump.

Remedies

Before starting repairs, you should figure out where and why the antifreeze is leaking, that is, make a diagnosis. Leaking hoses are easy to identify, as are fluid emissions from the tank - colored streaks are visible in the area of the lid. It’s more complicated with radiators - the holes in the pipes are usually small, they are blown by an air flow as they go, and leaks are invisible at first glance.

Advice. Fill the car's cooling system with antifreeze containing a fluorescent additive. It reflects the light of an ultraviolet lamp, making the slightest drips clearly visible.

Various problems can be resolved in the following ways:

- Try to clean and rinse the faulty valve of the expansion tank plug. If this does not help, the part should be replaced; it is inexpensive.

- A burst tank should be replaced. There is a practice of repairing plastic containers by soldering, but this option is not very reliable - the body may crack with the next pressure surge.

- Leaking hoses are definitely replaced. The exception is a crack at the very end, then the pipe is trimmed (if the length allows).

- A leaky pump seal must be replaced only on old Zhiguli VAZ 2101–07. On other cars it is replaced together with the water pump.

- Car radiators can be repaired if the cracks in the honeycombs are not the result of corrosion of the aluminum alloy. In any case, the unit must be removed and taken to a service center for inspection.

- A broken cylinder head gasket must be replaced immediately; you cannot drive with this damage. The work involves disassembling the engine; it should be entrusted to a master mechanic.

If one of the listed troubles happens to you on the road, you can add water to the cooling system to get to the garage or car service center. The exception is a gasket burnout, after which you cannot move on. Turn off the engine and tow the car.

A slow decrease in the level of antifreeze in a car’s cooling system is a fairly common problem, especially in cars of domestic manufacturers. Most experienced drivers have an idea where to look for the problem and how to deal with it. But in some situations, even they are not able to understand where the fluid goes from the expansion tank. To learn how to troubleshoot such problems, you need to know all the causes of fluid leaks - obvious and hidden.

Obvious damage

Antifreeze is designed to cool a car engine. A liquid with many additives is used in warm and cold seasons. Most compounds allow you to operate the machine at temperatures below - 60 degrees. A complete lack of coolant in the system will lead to rapid overheating of the engine, it will jam, and the car will fail. It is very expensive to overhaul the most expensive element in a car, so you need to carefully monitor the technical condition of all elements . The most common breakdowns that can lead to a rapid noticeable loss of antifreeze levels are:

- Damage to the main radiator. In this case, it is extremely difficult not to notice the leak, since smudges will form under the car. If you look under the bottom, you can find blue, green or red droplets. Most often, a radiator fails due to mechanical damage to thin tubes called honeycombs. In most cases, the culprit is stones that can fly out at high speed from under the wheels of other cars. Older cars that have been in use for more than 10 years may experience rust on the radiator tubes. In this case, they literally fall apart due to corrosion. The reasons for the destruction of the side plastic radiator tanks are similar.

- Failure of the heater radiator. The rate of leakage from the cooling system is approximately the same as when the main radiator is damaged, but diagnosing the failure is much more difficult. Very often, owners do not understand where the antifreeze goes if it does not leak anywhere. It is likely that the problem lies in mechanical damage to the heater radiator, and antifreeze drips onto the seal in the cabin. In this case, experienced car enthusiasts advise paying attention to the characteristic smell in the cabin and strong fogging of the windows in any weather. To finally verify the correctness of the diagnosis, it is necessary to disassemble the dashboard. If it is difficult to do such work yourself, you can contact a service center.

- Problems with the expansion tank or cap are the most common failure, so when there is a coolant leak, you should pay attention to these elements of the system first. It is not difficult to diagnose a breakdown if the seal of the lid is broken or there is a crack in the upper part of the barrel. In this case, the antifreeze will seep out and splash other elements under the hood. But if there is mechanical damage in the lower part of the barrel, it is extremely difficult to find out the cause of the liquid leak. Most car models will require complete removal of the element. If no damage is detected, then there is no need to rush to replace components. First of all, you need to check the bypass valve, which is built into the plug. Very often it becomes clogged, which leads to leakage.

- The connecting hoses inside the system are constantly subject to expansion due to exposure to high temperatures and subsequent restoration to their original dimensions. During the cold season, they can significantly shrink in size.

- Problems with tubes. Despite the fact that the connecting tubes are made of metal and usually last a very long time, they also fail due to mechanical damage. Most often the reason for this is the time factor. Corrosion can spread quite quickly, and it is not easy to notice the presence of a defect in time. Liquid can leak out very quickly through cracks in metal.

- Thermostat or pump defects. These two mechanisms in the car are designed to pump and regulate the flow of coolant. Depending on the car model and year of manufacture, the body of the parts can be made of metal or plastic. It is rarely possible to repair damaged elements, so most often it is recommended to replace important parts.

- Pump leaking. If during diagnostics it was possible to notice that a puddle of antifreeze forms at the place where the water pump is located, then in most cases the cause of the leak is the pump. But it is extremely difficult to accurately track the location of the leak, since modern car models are equipped with all kinds of casings, boots, seals, underbody protection and other elements that can accumulate draining antifreeze. The pump itself is a very durable and solid product, so most often a leak appears due to problems with the seal or gasket, which is located between the pump flange and the cylinder block. Additional difficulties await owners of front-wheel drive cars, since the pump is usually located under the timing cover.

Replacing pipes

The entire process of replacing pipes is divided into two stages:

- Dismantling;

- Installation.

Let's start with dismantling work.

- Unscrew the expansion tank cap to allow air into the system.

- Open the heater tap inside the passenger compartment by turning the control all the way to the right.

- Remove the crankcase protection by unscrewing all the mounting bolts.

- Prepare a container where you will drain the old coolant. It must be made of plastic with a volume of at least 10 liters. Choose a clean container if you want to refill this antifreeze.

- Clean the surfaces near the drain plug on the cylinder block and radiator. This will prevent dirt from getting into the coolant drain container.

- Place the container under the radiator drain, unscrew the cap and wait until the antifreeze comes out.

- Drain the fluid from the cylinder block in the same way.

- Wait until all the coolant has come out, then tighten the plugs.

- Start working on the interior by unscrewing the dashboard fasteners and moving them to the side. Move the front seats as far back as possible. This way you will provide yourself with more or less comfortable conditions.

- Unscrew the clamps from the coolant supply and return pipes from the heater tap. You will find it in the partition between the passenger compartment and the engine compartment.

- Remove the rubber pipes. If they are difficult to remove, you can pull them to the sides or cut them with a knife. They are still being replaced. Due to the hot coolant, the rubber sticks to the metal fittings, which complicates their dismantling.

- Be careful and careful, do not pull the tubes too hard. Otherwise, you risk damaging the connections of the fittings. And this will entail much more expensive repairs.

- Use a flathead screwdriver to remove the valve from the engine compartment.

- Using pliers or pliers, disconnect the holder from the heater tap drive rod.

- Clean the faucet and blow out the inside of it with compressed air.

- Sequentially remove all remaining pipes from the radiator and engine. Be sure to remember the sequence of their location so that there are no problems with reassembly.

Dismantling works

At this point, the dismantling work can be considered completed. But there is an equally important event ahead - the installation of new pipes.

- Clean all joints using wire brushes. Process the circumference of each fitting. Proceed carefully, take your time;

- Use a dry cloth to remove any remaining dirt. Even the smallest debris can clog the cooling system;

- Finish the edges of the clamps with a fine file. This way you will make them less sharp, and therefore the risk of damage to the rubber pipes is minimized;

- First put the clamps on the pipes so that they remain in a free position for now;

- If you cannot pull the pipe onto the fitting, try lubricating its edges with soap. This will make it easier for him to accept the pipe;

- Tighten the pipe, working carefully and consistently. Make sure that the installation is carried out without distortions;

- After installing the elements in place, check the tightness of the fit. Sometimes the rubber is too elastic or the diameter of the pipe is larger than required. Here it is better to immediately go to the store for a new set than to risk the cooling system;

- After making sure that the pipes are seated securely, tighten the clamps;

- Install all the new tubes into place, make sure once again that everything is done correctly, without distortions, the clamps are tightened properly;

- Check that the coolant drain plugs are properly tightened;

- Fill the expansion tank with previously drained or purchased new coolant;

- Wait about 10 minutes, then add a little more liquid. During this time, the antifreeze will pass through the system, fill the stove, radiator, and cylinder block;

- Tighten the reservoir cap and start the engine;

- Monitor the temperature sensor readings. If they rise higher than expected, immediately turn off the engine;

- Carefully open the cap of the expansion tank with antifreeze and press with a certain force on the upper pipe from the radiator;

- This will help remove excess air from the system. Repeat the procedure several times;

- Add coolant to the tank so that the antifreeze is at the required level. Start the engine again and check the behavior of the sensor. If everything is fine, you can safely continue to operate your VAZ 2109.

In many ways, the efficiency, reliability and duration of operation of the CO depends on the quality of the components used when replacing pipes.

Opel expansion tank valve repair

On many Opel cars, an expansion tank cap with two valves (GM 001834583) is installed, one of them is inlet and does not allow the pressure to drop below normal during vacuum. The second of the valves is the exhaust valve; it is the one that often operates too late, the reason for this is a very stiff spring. To make the stroke of the valve mechanism softer, the spring should be cut; to do this, you need to remove the parts from the cover. We carry out repairs as follows:

- Using a slotted screwdriver, remove the rubber seal by prying it from the side;

- turn the lid over and remove the mechanism;

- Using the same screwdriver, pry off the exhaust valve cap from the inside of the device and remove the spring;

- cut off approximately two and a half turns (there are 8 in total), remove a small part;

- we assemble the valve in the reverse order, pushing the cap with the spring down until it clicks, it is fixed with two latches;

- We put the mechanism and sealing gasket in place, screw on the cover, and check the operation of the device while running.

If the expansion tank still swells, you can trim the spring another half a turn. Usually this method works well; plugs with two valves are often installed not only on Opel, but also on Lada Kalina.

We brake correctly

If you need to stop as quickly as possible, on cars without ABS you need to try to brake to the point of locking the wheels. Once the tires start sliding on the asphalt, efficiency drops. On slippery roads, you should use intermittent braking - this allows you not only to stop faster, but also to avoid skidding.

On cars equipped with ABS, most of this work is done electronically: the driver only needs to press the pedal with sufficient force. By the way, if you want to get the most out of the brakes, press the brakes with all your might, even when you feel that the ABS has started working - you will gain a meter or two of braking distance.

Source

Hidden coolant leaks

These include all antifreeze leaks that do not leave noticeable marks and are diagnosed through a thorough check or after partial disassembly. The search for hidden defects should begin when obvious reasons for the loss of antifreeze are not found.

The reasons why fluid leaves the system unnoticed look like this:

- a malfunction of the expansion tank cap, whose valve is stuck in the open position;

- leaking pipes and radiator of the cabin heater;

- Broken gasket under the cylinder head.

Coolant level drops due to evaporation through a faulty cap

When the valve in the expansion tank plug is constantly open, the system communicates with the atmosphere and there is no pressure in it. For this reason, antifreeze slowly evaporates through the hole. The situation worsens when the engine is operating close to maximum: without pressure, antifreeze boils at a lower temperature and evaporates much more intensely. Despite the fact that there are no leaks anywhere.

The situation can be aggravated by a faulty thermostat that does not direct the heated liquid for cooling to the main radiator. The antifreeze, circulating in a small circle, then boils and begins to squeeze steam through the lid. The process is characterized by a critical increase in engine temperature.

When coolant is lost, the engine temperature rises to a critical level

Leak inside the cabin

This reason is considered hidden, since it will not be possible to detect such a leak without disassembling it - the antifreeze that slowly escapes through the leak is absorbed by the interior floor covering. But besides a decrease in the level in the tank, there are several indirect signs:

- if you carefully feel the carpet under the heater radiator and pipes, you can feel moisture;

- from the inside, the glass is covered with antifreeze fumes - a greasy, foggy coating that cannot be wiped off without detergent;

- There is a constant sweetish smell of coolant in the cabin.

To detect the location of the leak, you need to check the pipes and radiator of the stove

To identify the culprit - the pipes or the radiator itself, you need to do partial disassembly and get to these elements. In some brands of cars this is simple - you need to remove the decorative trims and glove compartment, in others - you need to disassemble the central panel. If no leaks are found on the hoses and joints, you will have to dismantle the stove and check its integrity by filling it with distilled water.

Cylinder head gasket failure

Since oil and liquid channels lead from the cylinder block to the cylinder head, symptoms of gasket failure can be different:

- when the outer rim of the gasket depressurizes, antifreeze gets out and flows down the wall of the block, which is clearly visible;

- In case of internal damage, antifreeze flows into the working cylinders, where it evaporates and is thrown out through the exhaust tract in the form of white smoke.

External gasket breakdown is a fairly rare failure. Much more common is the destruction of the internal partitions of the element and the ingress of liquid into the cylinders.

Antifreeze leaking from under the cylinder head floods the anthers around the engine

The flow of antifreeze into the active cylinders is very dangerous for the engine. The power unit may overheat and jam, and the cylinder head may crack due to water hammer. If you do not understand the colors of exhaust gases, diagnose the breakdown using additional signs:

- The energy of the burning fuel is not enough to completely evaporate the antifreeze, so part of it flows down the liners into the crankcase, mixes with the engine oil and forms a foamy emulsion. As a result, oil pressure drops sharply and engine temperature rises.

- Foreign liquid in the combustion chamber takes away energy for heating and evaporation, so engine power drops noticeably. The engine simply doesn't pull.

- A hole in the gasket connects the gas path, cooling and lubrication system. Because of this, a substance of an unknown dark color or light foam - an emulsion - may appear in the expansion tank.

Due to a burnt cylinder head gasket, the emulsion may enter the expansion tank

Although with such a leak there are no clear traces of antifreeze on the ground, many serious indirect signs will make it clear to the car owner that not everything is in order with the engine.

This excerpt (second) is taken from the article: https://maslo.biz/antifreeze/uhodit-a-podtekov-net.html

Causes of malfunctions

The main and most common reason why antifreeze is expelled from the expansion tank is a jammed or dirty cover bypass valve. In this case, the compressed air has nowhere to go, which is why the liquid breaks out at the weakest point - it flows along the thread of the plug or at the junction of one of the pipes.

Sometimes the cover valve gets stuck open and the system is constantly in contact with the atmosphere. As a result, the minimum boiling point of the liquid decreases, and more steam is formed in the nozzles. It leaves the system through a hole in the plug, causing the antifreeze level to slowly drop, with no leaks visible anywhere.

Now about other causes of problems:

- Antifreeze can escape from a crack in the tank itself, which is the result of a faulty cap valve. If all the connections are tight enough, the pressure often ruptures the container body.

- The pump (water pump) seal does not hold. The fluid leaking out hits the pulley and timing belt (or generator wires), splashing the cylinder block on one side.

- A leak in the cooling radiator and heater occurs due to corrosion or external mechanical influence. For example, a stone hitting the main radiator pipes from an oncoming car.

- Burnout of the gasket between the head and the cylinder block occurs due to the appearance of microcracks in it, into which gases leak from the combustion chambers. The crack expands and connects the chambers with water and oil channels, causing process fluids to mix and enter the cylinders.

Due to the listed problems, antifreeze constantly leaves the expansion tank and the car owner has to top it up almost every day. Gasket failure is a critical malfunction, fraught with overheating and oil starvation of the engine, leading to failure of the power unit and major repairs.

An indirect cause of antifreeze release may be a thermostat failure. When its valve is stuck in the closed position, the flow of heated fluid into the main radiator is blocked. Antifreeze circulates in a small circle with virtually no cooling, as a result of which it begins to boil and evaporate through the expansion tank plug.

A malfunction of the thermostat is indicated by an increase in engine temperature to 105 ° C or more, but the lower part of the radiator remains cold. If the temperature sensor is installed in the cylinder block, the electric fan will run constantly and you will hear it. In some cars, the sensor is mounted in the radiator (and it remains cold) and the electric fan does not save the engine from overheating.

What to do if antifreeze runs out?

Before you begin to combat this phenomenon, you should conduct a complete diagnosis of the vehicle. First of all, you need to determine what caused the breakdown. In the vast majority of cases, a decrease in the volume of antifreeze is associated with a leak from the cylinder block gasket. Replacing it completely solves the problem. You can do this at any service station or even yourself. To do this, you should adhere to the following algorithm:

- Purchase the necessary list of spare parts in advance. This process should be approached as responsibly as possible; it is best to select parts based on the vehicle code.

- Remove the old cylinder block cover. It is usually secured with 8 or 12 bolts. Before you begin, you should disconnect all components and pipes located on top. You will also have to remove filters and wiring.

- Unscrew the cylinder head. Do everything as carefully as possible, because the bolts will not be tightened too much. Because of this, antifreeze gets into the engine. Remove everything carefully so as not to damage anything.

- In some cases, the bolts may be too tight. Then you will have to remove all the heads. Keep in mind that if after removal you do not find any defects, you will no longer be able to install the old parts. Spare parts are disposable.

- Assembling the cylinder head gasket is carried out in the reverse order. It is important to carefully tighten the bolts to avoid stripping them. The head must be attached in a checkerboard pattern; a pressure gauge is also used to control the force.

In the vast majority of cases, after replacing the cylinder block gasket, the problem can be completely resolved. In rare cases, the block itself bursts. This usually happens in older cars. Try not to let your car get into this state.

Why does liquid leave if it is not leaking anywhere?

The loss of fluid from the system may be hidden. It is not immediately possible to determine the cause, since smudges are nowhere to be seen. Antifreeze can even escape through a microcrack formed on one of the system components, since the leaking compound simply evaporates when the engine is heated and no traces of leakage can be detected. The worst thing is if the coolant goes into the crankcase and mixes with the oil, and this leads to a reduction in the life of the crankshaft and camshaft bearings, even with the slightest ingress. You can determine if antifreeze has gotten into the oil by simply removing the oil dipstick from a cooled engine and droplets of water will be visible on it, and the oil itself will be very dark. Antifreeze can leak even through a damaged or poorly pressed head gasket.

Coolant can also escape through a leaky block gasket jumper and enter the cylinder. In this case, you should pay attention to the color of the exhaust - it will be bluish or white. It is possible that exhaust gases may gurgle in the expansion tank. In other cases, determining a coolant leak is quite difficult; it is best to contact a car service center.

At home, you can diagnose the system for leaks using pressure testing. The method is quite effective and simple. The essence of pressure testing is to pump pressure into the system using a conventional pump, which makes it possible to detect leaks at all points in the system where leaks have formed. By pressure testing it is possible to detect a leak in the manifold gasket, since it is impossible to detect a leak with a normal inspection - the coolant quickly evaporates when the engine is running.

Pressure testing of the car cooling system

Pressure testing of the system is carried out both in an auto repair shop and in a garage. At an auto repair center, the cost of work varies from 500 to 1 thousand rubles. Do-it-yourself crimping in your garage is quite simple, but you need to make a neck plug through which air will flow into the system. To make the neck you will need:

- tire valve;

- unnecessary radiator cap;

- drill.

The valve, or pipka in common parlance, is cut out of the old chamber along the contour of the circle, observing the diameter of the standard radiator cap gasket. A hole equal to the diameter of the pipe is drilled in the radiator plug.

After drilling a hole, it is necessary to process it with a round file to remove metal burrs

Having screwed the manufactured plug onto the neck, connect the pump to the valve and supply two pumps to the system, pressing the expansion tank plug with the palm of your hand. And it is also possible to supply air through the expansion tank.

The discharge pressure on the pressure gauge should not exceed 1 kg per square centimeter to avoid damage to the radiators

Pressure testing (pressure in the system) lasts about 2 minutes, after which all possible points of the cooling system are inspected for leaks. It is not recommended to use untested sealants and other chemicals added to the coolant to eliminate leaks, as this can cause irreparable damage to the entire cooling system, and these are completely different issues and a lot of money.

There are many reasons for coolant leaving the system, so it is rarely possible to quickly solve the problem. It is important to pay attention to all details and mechanisms, because a malfunction of any part of the system leads to disruption of the cooling of the power unit as a whole, which can lead to various problems.

How to prevent leakage

To prevent problems, you should follow a few simple rules. When checking the oil level, do not forget about the coolant. Also, when carrying out preventive work, you should monitor the reliability of fastening and the junction of tubes and hoses. Possible leaks are examined for cracks or other problems.

Only high-quality antifreeze should be poured into the tank. Different brands of coolant are often incompatible. The same incompatibility occurs if the antifreeze is heavily diluted with water. Therefore, the consistency of the cooling composition plays an important role. To know what antifreeze to fill, you should study the instructions for the car engine.

So, you already know where the antifreeze goes and you can easily deal with this problem.

Fuel pump strainer is clogged

Considering the quality of fuel supplied to our market, you can often encounter a similar problem. If you have checked everything listed above, but still have not figured out the problem, it is better to immediately go to the nearest auto parts store and purchase a new mesh there. The issue price is about 70 rubles.

Then, under the rear seats, we find the hatch and unscrew it, gaining access to the gas tank. We disconnect all the tubes and remove the fuel pump mount and remove the entire mechanism from the tank. A mesh will be attached to the supply to the fuel pump, remove it and install a new one. Afterwards we collect everything back into the gas tank.

Difficulties in diagnosis

Despite the fact that all such reasons are obvious, it is not always possible to independently determine where the antifreeze goes from the expansion tank. For example, very often damage to pipes remains invisible to the naked eye. In such cases, experienced car enthusiasts advise letting the engine cool completely, dry your hands thoroughly and carefully feel each connecting element. Microcracks will definitely make themselves felt , and coolant leaks will form on the hose.

The situation is more complicated with defects in clamps. The tricky part is that the liquid will accumulate in large drops at the joints, then fall on the heated surface and instantly evaporate. The characteristic smell of antifreeze will help you notice the presence of a problem. It can be felt when the hood is open or in the cabin. If the leak occurs due to a loose connection in a hard-to-reach place, then, most likely, you will have to carefully study the condition of the system in the pit.

Another nuance is related to the protective elements under the bottom of the car. For example, the cause of a leak may be a malfunction with the gaskets installed in the pump. But the drops will fall on the protective casing, and antifreeze stains will form in the area under the radiator. In this case, you can search for a long time for the true cause of the breakdown.

The best advice in this case is to remove the protective casing and carefully examine the condition of all the main components of the cooling system.

To be afraid or not

To begin with, I propose to understand the main points. Here it is important to distinguish when steam really poses a potential threat, that is, it indicates a malfunction, and when there is absolutely nothing to be afraid of.

If we are talking about absolutely safe and harmless smoke, then it should be white, have no odor and no traces of impurities. When the situation develops this way, we are talking about water vapor. Condensation has formed in the exhaust system, that is, a fairly large amount of moisture has accumulated. Now this water begins to actively evaporate due to gradual heating. It all turns into steam. It is in steam that this is important to remember. Because there is another concept. I'm talking about white smoke.

If we see such a picture when white smoke comes out of the exhaust, then it makes sense to suspect the engine or cooling system of some kind of malfunction.

During normal engine operation, the smoke coming out of the chimney should be transparent or close to it. However, on older cars and rather worn-out engines, the smoke becomes more toxic and dirtier.

What's the result?

If this element is present, then checking the catalyst for clogging will be your first priority.

Let's sum up the intermediate results. If white smoke is coming out of your car's exhaust pipe, this indicates high levels of moisture inside the exhaust system. It is important to pay close attention to this nuance. When the engine warms up, all the water should evaporate. Therefore, steam and condensate no longer come out of the pipe. But if the engine has warmed up and smoke continues to pour out, then this is an obvious sign of a problem. Something needs to be done. First, find out the reasons.

There are several possible reasons for this situation.

Let's look at them, and take a separate look at the features of diesel and gasoline internal combustion engines.

Antifreeze leak due to a broken head gasket

If the cylinder head gasket is broken, the antifreeze from the OS will also decrease, and the liquid does not always go into the oil sump; it can enter the cylinder, and then fly out of the muffler along with the exhaust gases. But in any case, with a broken cylinder head:

- the engine is adjusting, or one (two) cylinders are not working fully;

- craving worsens;

- detonation appears;

- the engine overheats.

If the gasket has just begun to “etch”, all these signs are almost unnoticeable, but the car still loses power to some extent, the engine heats up, and the coolant gradually leaves. The main signs of a broken gasket:

- thick white smoke from the muffler pipe on a warm internal combustion engine;

- cleanly washed spark plug electrodes of an idle cylinder;

- emulsion instead of engine oil;

- constant ejection of antifreeze from the expansion tank;

- presence of air bubbles in the coolant.

If you don’t have some experience, you shouldn’t undertake replacing the PGBC; there are many nuances here that you may not be aware of. The fact is that if the gasket is broken, the surface of the cylinder head can be deformed, the cylinder head in the area of the combustion chamber, the partition on the block between the cylinders can burn out, and often the piston rings “shrink” when overheated.

Only an experienced specialist can determine the condition of the engine after a gasket breakdown, and it is not always possible to “get away” with just replacing it; after the engine overheats, even major repairs may be required.

Tips for choosing a radiator

Let's look at the main nuances when choosing a stove for a VAZ 2114. As you know, the factory-produced VAZ 2114 heater device has a high level of required heat transfer. But the required model is simply not available for free sale; in this case, we purchase what is available. Naturally, the characteristics of a used radiator are absolutely no good, the reason is obvious, in a couple of months you will have to change the radiator again, in a word, you will be throwing money down the drain. In this situation, a better solution would be to overpay a little and purchase a new device.

We recommend: Advantages of rubber mats for car interiors over pile mats

Based on consumer reviews, radiators from the manufacturer DAAZ are in great demand, because The quality indicators of the produced models are met, the heat transfer parameters are also at their best. As for the material from which the VAZ 2114 stove is made, it is impossible to confidently determine the leader among aluminum or copper radiators. Each has advantageous indicators and certain disadvantages, such as heat transfer characteristics and operating life.