It is known that the operating efficiency of an automobile internal combustion engine is directly dependent on the efficiency factor. Engine efficiency is expressed as the ratio of power transferred to the crankshaft and pistons. Modern internal combustion engines are more efficient than their outdated counterparts. For example, a 1.6 liter engine previously developed a power of no more than 70 horsepower, but now this parameter often reaches 150 hp. With.

More about losses

Looking ahead, we can confidently say that the efficiency of a gasoline engine ranges from 20 to 25%. And there are many reasons for this. If we take the incoming fuel and convert it into percentages, then we seem to get “100% of the energy” that is transferred to the engine, and then there are losses:

1) Fuel efficiency . Not all the fuel is burned, a small part of it goes with the exhaust gases, at this level we already lose up to 25% efficiency. Of course, now fuel systems are improving, an injector has appeared, but it is far from ideal.

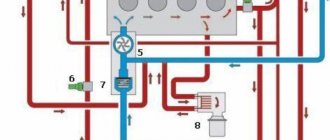

2) The second is thermal losses and . The engine warms itself and many other elements, such as radiators, its body, and the liquid that circulates in it. Also, some of the heat leaves with exhaust gases. All this results in up to 35% loss of efficiency.

3) The third is mechanical losses . ON all kinds of pistons, connecting rods, rings - all places where there is friction. This can also include losses from the load of the generator, for example, the more electricity the generator generates, the more it slows down the rotation of the crankshaft. Of course, lubricants have also made progress, but again, no one has yet been able to completely overcome friction - losses are still 20%.

Thus, the bottom line is that the efficiency is about 20%! Of course, among the gasoline options, there are standout options in which this figure is increased to 25%, but there are not many of them.

That is, if your car consumes fuel 10 liters per 100 km, then only 2 liters of them will go directly to work, and the rest are losses!

Of course, you can increase the power, for example, by boring the head, watch a short video.

If you remember the formula, it turns out:

This is interesting: Brake slave cylinder - how to prevent major troubles?

Mechanism efficiency - what formula is used to calculate

Man has come up with various mechanisms that can be used to lift heavy loads to a certain height. Thus, a winch was invented to lift a bucket of water from a well, and a jack was invented to lift a car. Using a winch and an inclined plane, the Egyptians built their grandiose pyramids.

When using these devices, a person rarely remembers their efficiency. As an example, consider this indicator for an inclined plane .

The principle of calculating efficiency remains unchanged: you need to find the ratio of useful work to all energy expended. That is, again we use the general formula (1), making the appropriate transformations.

Suppose a body of mass m needs to be lifted (more precisely, pushed or pulled) to a height h. At a constant rate of ascent, the useful work will be equal to the product of gravity (mg) and height (h).

The work expended is determined by the arbitrariness of the push or pull force F on the length of the inclined plane L. Note that the push (traction) force is used to overcome the friction force Ftr.

Thus, the efficiency of such a simple mechanism can be calculated using the formula:

A simple analysis shows that the efficiency of an inclined plane is inversely proportional to the friction force and the length of the ramp. The latter, in turn, depends on the angle of inclination: the greater it is, the shorter the ramp.

Engine thermal efficiency. Not so scary physics.

Typically, if someone hears the slogan “engine thermal efficiency,” they immediately change the topic. You can talk about engines about their power, about their fuel consumption or - earning the respect of your interlocutors as an expert - about performance systems such as Diesel, Otto, Wankel and Atkinson. But thermal efficiency sounds like physics homework, that is, it causes disgust and negative reactions. Meanwhile, all this merges into one...

Engine efficiency - denoted by the Latin symbol η (eta) - is a parameter that characterizes a given engine and means how much supplied heat is converted into useful work. In the case of an internal combustion engine, this is the conversion of thermal energy resulting from the combustion of fuel into mechanical energy released by the engine as a result of the rotation of the crankshaft.

The values of this efficiency vary for different types of engines and, for example, for spark-ignition engines it is about 0.30–0.36, and for diesel engines it is about 0.40–0.45. This means nothing more than that when filling a tank with 50 liters of fuel, only 15-18 liters of gasoline and 20-22.5 liters of diesel fuel are used to drive the vehicle components. The rest is irretrievably lost.

Improved engine efficiency

Given the increased public demand for efficient, economical and comfortable cars, today scientists and experts from different countries are participating in programs to improve automobile engines in order to bring their efficiency to 80% or higher.

To do this, various structural modifications are used (for example, turbocharging), the metal components of the internal combustion engine base are replaced with lighter alloys that can retain heat and reduce the level of friction to a minimum at the minimum required costs.

All this becomes the basis for the production of more compact, lightweight engines capable of converting most of the initially received energy into useful work. Thus, all this allows for real savings in the further operation and maintenance of the machine.

At the same time, much attention is paid to improving and cleaning existing elements (fuel, cooling systems, lubrication, fuel supply and gas exhaust), because, as we noted earlier, in this way efficiency can be increased even without changing individual parts. It is enough to simply fill in the correct fuel, reduce the level of heat transfer during the operation of the internal combustion engine, or exhaust exhaust

Another point of effective use of a vehicle is the optimal level of vehicle loading. Maintaining an average speed, correct gears, and not trying to show off your excessive skill, you will be able to significantly reduce fuel consumption. You can also achieve optimal power and speed of the car in certain conditions.

We recommend that you familiarize yourself and find out what a viscous coupling is in a car.

Share information with friends:

Power losses - where and why

- fuel efficiency - the fuel does not burn completely, a small part of it simply flies out into the exhaust pipe. At this stage, 25% is lost;

- thermal - the engine heats not only itself, but also its other elements. To obtain heat, energy is required, this is loss. Another 35% is spent on them;

- mechanical - friction occurs during the movement of mechanisms. Of course, lubricants weaken its effect, but it has not yet been possible to completely defeat it. That's another 20%.

- Google+

- LJ

- Blogger

At the output we find that the engine efficiency is only 20-25%. In fact, if a car consumes 10 liters of gasoline per 100 km, then only 2 liters will be spent on work, the rest is losses.

Which engine has the highest efficiency?

Now I want to talk about gasoline and diesel options, and find out which of them is the most efficient.

To put it in simple language and without getting into the weeds of technical terms, if you compare the two efficiencies of gasoline and diesel units, the more efficient of them is, of course, diesel and here’s why:

1) A gasoline engine converts only 25% of energy into mechanical energy, but a diesel engine converts about 40%.

2) If you equip a diesel type with turbocharging, you can achieve an efficiency of 50-53%, and this is very significant.

So why is it so effective? It's simple - despite the similar type of work (both are internal combustion units), diesel does its job much more efficiently. It has greater compression, and the fuel ignites using a different principle. It heats up less, which means there is a saving on cooling, it has fewer valves (saving on friction), and it also does not have the usual ignition coils and spark plugs, which means it does not require additional energy costs from the generator. It operates at lower speeds, there is no need to frantically spin the crankshaft - all this makes the diesel version a champion in terms of efficiency.

How can you increase efficiency

Modern science is constantly looking for ways to increase the efficiency of engines and individual mechanisms, introducing new technical solutions and technological innovations.

The higher the efficiency, the more economical the engine will be, the more energy resources will be saved.

Heat engine

From formula (2) it follows that there are two ways : a) increasing the heater temperature; b) lowering the temperature of the refrigerator. Both paths are unpromising.

The heater cannot be heated indefinitely, since any material has a heat resistance limit. The refrigerator is almost always the environment, and introducing an additional heat exchanger (for example, a cylinder with liquid nitrogen) into the system is impractical: this will sharply increase the weight, dimensions and cost of the engine.

It has been established that the efficiency is not affected by the characteristics of the working fluid. What remains?

But there remain many practically feasible methods, such as reducing friction in mechanical components, minimizing heat loss by achieving the most complete combustion of fuel, creating streamlined shapes to reduce head-on comparison (air or water), etc.

an efficiency of 30-40% is currently considered a good indicator , scientists and practitioners have something to work on.

Comparison of efficiency of heat engines - gasoline and diesel

If we compare the useful power, we immediately note that the gasoline one is not as efficient. Its value is only 25-30%, while for diesel it is -40%.

Despite the similarity of the units, they have different types of mixture formation.

- In a gasoline engine, the pistons operate at higher temperatures, which requires good cooling. Therefore, thermal energy that could be transformed into mechanical energy is wasted, thereby reducing efficiency.

- In a diesel engine, the working mixture ignites during compression, so the pressure in the cylinders is much higher.

In addition, the motor is much smaller and more environmentally friendly. At low speeds and large displacement, efficiency levels can increase to 50%.

- Google+

- LJ

- Blogger

This is interesting: Welding a car body: how to do it yourself correctly

Power of different devices

According to statistics, up to 25% of energy is lost during operation of the device. When an internal combustion engine operates, fuel is partially burned. A small percentage escapes into the exhaust pipe. When starting, the gasoline engine heats itself and its components. The loss takes up to 35% of the total power.

When mechanisms move, friction occurs. Lubricant is used to loosen it. But it is unable to completely eliminate the phenomenon, so up to 20% of energy is wasted. An example on a car: if the consumption is 10 liters of fuel per 100 km, 2 liters will be required for movement, and the remainder, equal to 8 liters, is a loss.

If we compare the efficiency of gasoline and diesel engines, the useful power of the first mechanism is 25%, and of the second - 40%. The units are similar to each other, but they have different types of mixture formation:

- Gasoline engine pistons operate at high temperatures and therefore require good cooling. Heat that could be converted into mechanical energy is wasted, which contributes to a decrease in efficiency.

- In the circuit of a diesel device, the fuel ignites during the compression process. Based on this factor, we can conclude that the pressure in the cylinders is high, while the engine is more environmentally friendly and smaller than the first analogue. If you check the efficiency at low operation and high volume, the result will exceed 50%.

Formula for working in physics

For mechanical work, the formula is simple: A = F x S. If deciphered, it is equal to the applied force along the path along which this force acted. For example, we lift a load weighing 15 kg to a height of 2 meters. The mechanical work to overcome the force of gravity will be equal to F x S = mxgx S. That is, 15 x 9.8 x 2 = 294 J. If we are talking about the amount of heat, then A in this case is equal to the change in the amount of heat. For example, water was heated on the stove. Its internal energy has changed, it has increased by an amount equal to the product of the mass of water and the specific heat capacity by the number of degrees by which it has heated up.

Solving Examples

Problem 1. A train at a speed of 54 km/h develops a power of 720 kW. It is necessary to calculate the traction force of power units. Solution: To find the power, use the formula N=F x v. If you convert the speed to SI units, you get 15 m/s. Substituting the data into the equation, it is determined that F is equal to 48 kN.

Problem 2. The mass of the vehicle corresponds to 2200 kg. A car, going uphill at a slope of 0.018, covers a distance of 100 m. The speed reaches 32.4 km/h, and the friction coefficient corresponds to 0.04. It is necessary to determine the average power of the car when driving. Solution: the average speed is calculated - v/2. To determine the traction force of the motor, a drawing is made that displays the forces acting on the machine:

- severity - mg;

- ground reaction - N;

- friction - Ftr;

- thrust - F.

The first quantity is calculated according to Newton's second law: mg+N+Ftr+F=ma. For acceleration, the equation a=v2/2S is used. If you substitute the last values and use cos, you get the average power. Since the acceleration is considered constant and equal to 9.8 m/s2, therefore v= 9 m/s. Substituting the data into the first formula, you get: N= 9.5 kBt.

When solving complex problems in physics, it is recommended to check the compliance of the units of measurement provided in the conditions with international standards. If they differ, it is necessary to translate the data taking into account the SI.

Previous

Physics Pressure formula - examples and calculation conditions

Next

PhysicsAbsolutely elastic and inelastic impact of two bodies - formulas and examples of calculations

Asynchronous motor and stirling

Today, asynchronous machines are presented on the market, most of which are electric. An asynchronous mechanism converts electrical energy into mechanical energy.

Their main advantages:

- ease of manufacture and relatively low cost;

- high reliability;

- operating costs are low.

- Google+

- LJ

- Blogger

The efficiency formula is calculated as follows: η = P2 / P1 = (P1 - (Pob - Ps - Pmx - Pd)) / P1, where Rob = Pob1 + Rob2 - the total losses in the windings of an asynchronous motor. For most modern mechanisms of this type, the coefficient reaches 80 - 90%.

Another internal combustion engine that can be powered by any heat source is the Stirling engine.

It should be noted that such mechanisms are used on spacecraft and modern submarines.

- Google+

- LJ

- Blogger

It operates at any temperature, does not require additional systems to start, and their efficiency is 50-70 higher than that of conventional engines.

Steam engine efficiency

To operate the power unit, it is necessary to convert the thermal energy generated by the combustion of the air-fuel mixture into mechanical energy. Previously, steam engines were used in which solid fuel (coal, firewood) was burned, the pistons were set in motion under the influence of expanding steam. The dimensions of such power plants were several times larger in size than modern engines running on other types of fuel.

In piston-type steam engines, the efficiency does not exceed 10%. Currently, such devices are almost never used, since it is believed that there are no fundamental ways to increase their efficiency.

In order to increase this indicator, heat sources with the lowest cost are used. For example, large thermal power plants use nuclear energy. In addition, modern technologies are used in which waste heat does not go uselessly into the atmosphere, but is used for heating systems in apartment buildings. The losses here are no more than 10 percent. Modern steam turbines have an efficiency coefficient of 50 - 60%.

Interesting: In developed European countries (Switzerland, Austria), steam locomotives are very popular. They are used as tourist transport for transporting passengers along mountain roads. Thanks to numerous improvements, the economic performance of steam locomotives often rivals both electric and diesel locomotives.

Electric motor efficiency and power

Efficiency and power are what you should first pay attention to when choosing an AIR asynchronous electric motor. The essence of the operation of any electric engine is that electrical energy, with accompanying losses, is converted into mechanical energy. The lower the losses during this process, the higher its efficiency and the more efficient the electric motor. But, despite the importance of efficiency, do not forget about the power of the motor. After all, even with extremely high efficiency and the power it produces, it may not be enough to solve the problems you need. Therefore, when purchasing, it is very important to know not only what the efficiency of the electric motor is, but also what useful power it can produce on its shaft. Both of these values must be specified by the manufacturer. Sometimes it happens that you don’t have access to the motor’s passport (for example, if you buy it secondhand, which is highly not recommended) and you have to independently calculate such important parameters. First, it’s worth defining what the coefficient of performance, or simply efficiency, is. And so, this is the ratio of useful work to energy expended.

Determination of electric motor efficiency

It turns out that in order to determine this parameter it is necessary to compare the energy it produces with the energy it needs to function. The efficiency is calculated using the expression:

η=P2/P1 where η is efficiency

P2 – useful mechanical power of the electric motor, W P1 – electrical power consumed by the motor, W;

Efficiency is a value ranging from 0 to 1; the closer its value is to unity, the better. Accordingly, if the efficiency has a value of 0.95, this shows that 95 percent of electrical energy will be converted into mechanical energy and only 5 percent will be losses. It is worth noting that efficiency is not a constant value, it can vary depending on the load, and it reaches its maximum at loads around 80 percent of the rated power, that is, that stated by the motor manufacturer. Modern asynchronous electric motors have a nominal efficiency (declared by the manufacturer) of 0.75 - 0.95. Losses during engine operation are mainly caused by heating of the motor (part of the consumed energy is released in the form of thermal energy), reactive currents, bearing friction and other negative factors. Motor power refers to the mechanical power that it produces on its shaft. In general, power is a parameter that shows how much work a mechanism does in a certain unit of time.

The efficiency of an electric motor is a very important parameter that determines, first of all, the efficiency of using the energy resources of an enterprise . As you know, the efficiency of an electric motor decreases significantly after its repair; we wrote about this in this article. As the efficiency decreases, electricity losses will correspondingly increase. Recently, energy-efficient electric motors from different manufacturers have been gaining popularity; in Russia, motors produced by Vladimir Electric Motor Plant OJSC are popular. Any asynchronous electric motors are presented in the product catalog. You can find additional useful information in the catalog of articles.

Other similar indicators [edit | edit code]

Not all indicators characterizing the efficiency of energy processes correspond to the above description. Even if they are traditionally or erroneously called "efficiency", they can have other properties, in particular exceeding 100%.

Boiler efficiency

The efficiency of fossil fuel boilers is traditionally calculated based on the lower calorific value; it is assumed that the moisture of the combustion products leaves the boiler in the form of superheated steam. In condensing boilers, this moisture is condensed, and the heat of condensation is usefully used. When calculating efficiency based on the lower calorific value, it may end up being greater than one. In this case, it would be more correct to calculate it by the higher calorific value, which takes into account the heat of steam condensation; however, the performance of such a boiler is difficult to compare with data on other installations.

Heat pumps and chillers

The advantage of heat pumps as heating equipment is the ability to receive more heat than the energy consumed for their operation. A refrigeration machine can remove more heat from the cooled end than the energy expended to organize the process.

The efficiency of machines is characterized by the refrigeration coefficient

(English equivalent of COP)

ε X = QX / A =Q_ /A> ,

where QX > is the heat taken from the cold end (in refrigeration machines the cooling capacity); A is the work (or electricity) spent on this process.

For heat pumps, the term transformation ratio

ε Γ = Q Γ / A =Q_/A> ,

where Q Γ > is the heat of condensation transferred to the coolant; A is the work (or electricity) spent on this process.

In an ideal machine Q Γ = QX + A =Q_ +A>, hence for an ideal machine ε Γ = ε X + 1 =varepsilon _ +1>

The reverse Carnot cycle has the best performance indicators for refrigeration machines: it has a coefficient of performance

ε = TXT Γ − TX over -T_ >>> ,

where T Γ > , TX > are the temperatures of the hot and cold ends, K . This value, obviously, can be arbitrarily large; Although it is difficult to approach practically, the coefficient of refrigeration can exceed unity. This does not contradict the first law of thermodynamics, since, in addition to the energy A

(for example, electrical),

the energy taken from the cold source also goes

Q.

Maximum efficiency value of an ideal engine

How to find the efficiency of an engine whose value would be ideal and equal to 100%. Is this possible? The answer to this question was given back in 1824 by engineer S. Carnot. In his developments, he came up with an ideal machine, where the formula for the efficiency of a heat engine looks like this: η = (T1 - T2)/ T1.

- Google+

- LJ

- Blogger

As a result, it was found that a 100% coefficient can be achieved only if the cooler temperature is equal to absolute zero, and this is impossible, since it cannot be lower than the air temperature.

Examples of efficiency calculations

Example 1. It is necessary to calculate the coefficient for a classic fireplace. Given: the specific heat of combustion of birch firewood is 107 J/kg, the amount of firewood is 8 kg. After the wood burned, the temperature in the room increased by 20 degrees. The specific heat capacity of a cubic meter of air is 1.3 kJ/kg*deg. The total cubic capacity of the room is 75 cubic meters.

To solve the problem, you need to find the quotient or ratio of two quantities. The numerator will be the amount of heat that the air in the room received (1300J*75*20=1950 kJ). The denominator is the amount of heat released by wood during combustion (10000000J*8 =8*107 kJ). After calculations, we find that the energy efficiency of a wood-burning fireplace is about 2.5%. Indeed, modern theory about the design of stoves and fireplaces says that the classic design is not energy efficient. This is due to the fact that the pipe directly discharges hot air into the atmosphere. To increase efficiency, a chimney with channels is installed, where the air first gives off heat to the masonry of the channels, and only then comes out. But in fairness, it should be noted that during the combustion of a fireplace, not only the air, but also the objects in the room are heated, and part of the heat goes out through elements that are poorly insulated - windows, doors, etc.

What kind of lighting do you prefer?

Built-in Chandelier

Example 2. The car traveled 100 km. The weight of the car with passengers and luggage is 1400 kg. In this case, 14 liters of gasoline were consumed. Find: Engine efficiency.

To solve the problem, it is necessary to relate the work of moving the load to the amount of heat released during fuel combustion. The amount of heat is also measured in Joules, so there is no need to convert to other units. A will be equal to the product of force and path (A=F*S=m*g*S). The force is equal to the product of mass and the acceleration of gravity. Useful work = 1400 kg x 9.8 m/s2 x 100000 m = 1.37 * 108 J

The specific heat of combustion of gasoline is 46 MJ/kg=46000 kJ/kg. We will consider eight liters of gasoline to be approximately equal to 8 kg. The heat released was 46*106*14=6.44*108 J. As a result, we obtain η ≈21%.

Power and torque

When the displacement figures are the same, the power of a naturally aspirated petrol engine is higher, but is only achieved at higher speeds. The unit needs to be “twisted” more strongly, while losses increase, and fuel consumption increases accordingly. In addition, it is worth mentioning torque, under the influence of which the force that is transmitted from the engine to the wheels increases and contributes to the movement of the car. Gasoline engines reach their maximum torque level only at high speeds.

An atmospheric diesel engine with the same parameters reaches peak torque only at low speeds. This contributes to less fuel consumption required to perform work, resulting in higher efficiency and more economical fuel consumption.

Compared to gasoline, diesel fuel generates more heat, since the combustion temperature of diesel fuel is much higher, which contributes to higher detonation resistance. It turns out that a diesel engine has much more useful work done on a specific amount of fuel.

This is interesting

Science has proven that the efficiency of any mechanism is always less than one. This is due to the second law of thermodynamics.

For comparison, the efficiencies of various devices:

- hydroelectric power stations 93-95%;

- NPP – no more than 35%;

- thermal power plants – 25-40%;

- gasoline engine - about 20%;

- diesel engine - about 40%;

- electric kettle – more than 95%;

- electric vehicle – 88-95%.

Science and engineering do not stand still. Ways are constantly being invented to reduce heat loss, reduce friction between parts of the unit, and increase the energy efficiency of equipment.

Summary

In the production of modern internal combustion engines, manufacturing plants invest heavily in the pursuit of increasing the efficiency of their products by at least a few percent. To this end, engineers are improving and complicating motor designs and using new materials to manufacture individual elements.

Sometimes it happens that the financial costs of developers are inappropriate, in comparison with the obtained result of 2 - 3%. Therefore, it may be more profitable to subject standard engines to various boosts, fine-tuning, and modifications using tuning improvements in small repair shops. As a result, the power and other traction characteristics of power units increase.

Coefficient of performance (COP) is a widely used characteristic of the efficiency of some system or device. In our case, this system is the internal combustion engine. It would seem, what kind of efficiency can we talk about in the world of modern engines? Isn’t it equal to 100 percent? But it turns out that just as there is no ideal black or white in our world, there is no car in which all the energy received from burning fuel is completely converted into mechanical energy, and the latter, in turn, into useful energy that presses the driver of the car into his seat.

What does the efficiency depend on?

This value depends on how much total perfect work can turn into useful work. First of all, it depends on the design of the mechanism or machine itself. Engineers all over the world are struggling to increase the efficiency of machines. For example, for electric vehicles the coefficient is very high - more than 90%.

But an internal combustion engine, due to its design, cannot have η close to 100 percent. After all, fuel energy does not act directly on the rotating wheels. Energy is dissipated at each transmission link. Too many transmission links, and some of the exhaust gases still exit into the exhaust pipe.

About diesel fuel efficiency

FROM a higher efficiency value, fuel efficiency follows. So, for example, a 1.6-liter engine can consume only 3–5 liters in the city, in contrast to the gasoline type, where the consumption is 7–12 liters. A diesel engine has much more torque, the engine itself is often more compact and lighter, and, recently, also more environmentally friendly. All these positive aspects are achieved thanks to a higher compression ratio; there is a direct relationship between efficiency and compression, see the small plate.

However, despite all the advantages, it also has many disadvantages.

As it becomes clear, the efficiency of an internal combustion engine is far from ideal, so the future clearly belongs to electric options - all that remains is to find efficient batteries that are not afraid of frost and hold a charge for a long time.

Read more: Replacing the window lifter mechanism of a VAZ 2107

I’ll finish here, read our AUTOBLOG.

( 26 votes, average: 4.08 out of 5)

Surely, many car enthusiasts have wondered how the power of an internal combustion engine corresponds to its utility. It is assumed that the higher the efficiency of a power system, the more efficient it is. Speaking in absolute terms, today the highest coefficient is for electric motors; in some models it reaches about 95 percent. As for internal combustion engines, for most of them, regardless of the type of fuel, this figure is very far from ideal figures.

Internal combustion engine efficiency

Of course, modern engines are much more efficient than those that were developed and released ten years ago, this is due to objective reasons for the development of technology. At the beginning of the 2000s, a one and a half liter engine produced an average of about seventy horsepower, and this was normal. Today, the number of heads in a herd of the same volume can reach more than 150. Every little step in terms of increasing the engine power factor is given to manufacturers through painstaking work and trial, error and success.

Designations

Lowercase η

- In optics, the refractive index of an optical medium (although the letter n

is used more often). - In thermodynamics, the efficiency of a Carnot heat engine.

- In particle physics there are η-mesons.

- In statistics, η²

is the “partial regression coefficient.” - In lambda calculus - η-conversion

- In fluid dynamics, dynamic viscosity, also denoted by the letter μ.

Wikimedia Foundation. 2010.

See what “This (letter)” is in other dictionaries:

Y (letter) - Cyrillic letter Y Cyrillic A B C D Y D ... Wikipedia

Ө (letter) - Cyrillic letter Ө Cyrillic A B C D Ґ D ... Wikipedia

this is a letter, caste, this Dictionary of Russian synonyms. this noun, number of synonyms: 3 • letter (103) • caste ... Dictionary of synonyms

Eta - Greek alphabet Αα Alpha Νν Nu Ββ ... Wikipedia

Ѫ (letter) - Big yus Cyrillic A B C D Ґ D ... Wikipedia

ETA - This term has other meanings, see ETA. This term has other meanings, see Eta (letter). Basque country and Basque freedom. Euskadi Ta Askatasuna ... Wikipedia

That scary letter “R” - The Big C Genre Comedy... Wikipedia

Letter zy - This article is about phraseological units. For the computer program, see Bukva zu. Wiktionary has an article “... Wikipedia

letter - Sign (alphabetic), writing (plural), hieroglyph (hieroglyph), scribble, runes. I made some scribbles and read it. ... Wed. sign. Dictionary of Russian synonyms and similar expressions. under. ed. N. Abramova, M.: Russian dictionaries, 1999. letter ... Dictionary of synonyms

Letter A - Cyrillic letter A Cyrillic A B C D Ґ D ... Wikipedia

Let's say we are relaxing at the dacha, and we need to fetch water from the well. We lower the bucket into it, scoop up the water and begin to lift it. Have you forgotten what our goal is? That's right: get some water. But look: we are lifting not only the water, but also the bucket itself, as well as the heavy chain on which it hangs. This is symbolized by a two-color arrow: the weight of the load we lift is the sum of the weight of the water and the weight of the bucket and chain.

Thermal Cycle Analysis

The thermal cycle includes four thermodynamic basic processes. First, the state of the working fluid is transformed, and then it returns to its original state: compression, heat generation, expansion and heat removal.

Each of these processes is carried out according to the following scheme, which determines the conditions for the implementation of the cycle:

- Isothermal - work is performed at a constant temperature.

- Isobaric - the operating cycle is implemented at constant pressure.

- Isometric - the thermal process occurs at a constant volume

- Adiabatic - the cycle is carried out at constant entropy.

In order for the process to be as close to reversible as possible, there are two ways to move the piston: isothermal - this means that heat gradually enters or leaves the reservoir at a temperature infinitely different from the temperature of the gas in the piston, and adiabatic, in which no heat exchange occurs at all, the gas acts like a spring.

Thus, when heat is added and the gas expands, the temperature of the gas must remain the same as that of the heat source, with the gas expanding isothermally. Likewise, it will later be compressed in the cycle isothermally, releasing heat.

To find out efficiency, you need to follow the engine through its entire cycle, find out how long it runs, how much heat is taken from the fuel, and how much energy is lost in preparation for the next cycle.

The thermal cycle characteristics associated with a heat engine are typically described using two state diagrams : a PV diagram showing the pressure-volume relationship and a TS diagram showing the temperature-entropy pair.

For a constant mass of gas, the operation of a heat engine is a repeating cycle, and its PV diagram will look like a closed figure.

How does a heat engine work?

Any heat engine consists of three main parts:

- working fluid;

- heater;

- refrigerator.

Engine operation is based on a cyclic process.

The heater, using, for example, combustion of the fuel mixture, releases a large amount of heat and transfers it to the working fluid.

A working fluid, such as steam, gas or liquid, expands when heated and does work, for example, rotates a turbine or moves a piston.

A refrigerator is needed to return the working fluid to its initial state. It absorbs part of the energy of the working fluid. This ensures cycling and the heat engine runs continuously.

Ideal Carnot heat engine

The Carnot engine model was developed by the French physicist S. Carnot.

The working part of a Carnot engine is a piston in a gas-filled cylinder. The Carnot engine is an ideal machine; it is only possible in theory. Therefore, in it the friction forces between the piston and the cylinder and heat losses are considered equal to zero.

Mechanical work is maximum if the working fluid performs a cycle consisting of two isotherms and two adiabats. During isothermal expansion, gas work is performed due to the internal energy of the heater. In an adiabatic process - due to the internal energy of the expanding gas. In this cycle there is no contact of bodies with different temperatures, so heat transfer without work is eliminated. This cycle is called a Carnot cycle.

An adiabatic process is a thermodynamic process that occurs without heat exchange with the environment (Q = 0).

An isothermal process is a thermodynamic process that occurs at a constant temperature. Since the internal energy of an ideal gas depends only on temperature, the amount of heat Q transferred to the gas goes entirely to doing work A (Q=A).

The Carnot engine operates as follows:

- The cylinder comes into contact with a hot reservoir and the gas expands at a constant temperature. During this phase, the gas receives heat from the hot reservoir.

- The cylinder is surrounded by thermal insulation, due to which the amount of heat available in the gas is conserved. The gas continues to expand until its temperature drops to that of the cold thermal reservoir.

- In the third phase, the thermal insulation is removed. The gas in the cylinder, being in contact with a cold reservoir, is compressed, thereby transferring some of the heat to the cold reservoir.

- When the compression reaches a certain point, the cylinder is again surrounded by thermal insulation. The gas is compressed by raising the piston until its temperature is equal to the temperature of the hot reservoir. After this, the thermal insulation is removed and the cycle is repeated again from the first phase.

Note

The greater the difference between the temperatures of the heater and refrigerator, the greater the efficiency of the Carnot engine.

Types of power systems

The carburetor option involves mixing air and gasoline in the inlet pipe of the carburetor. Recently, the production of such engine options has been significantly reduced due to the insignificant efficiency of such engines and their inconsistency with modern environmental standards.

In injection engine versions, fuel is supplied using one injector (nozzle) into the central pipeline.

In the case of distributor injection, fuel enters the engine through several injectors. In this case, the maximum power increases, which significantly increases the efficiency of the diesel engine.

At the same time, gasoline consumption and toxicity of processed gases are reduced due to a fixed fuel dosage by electronic control systems of the automobile engine.

When discussing the efficiency of a modern diesel engine, you need to know about the injection system of the gasoline mixture into the storage chamber. If fuel is supplied in portions, this guarantees that the engine runs on lean mixtures, which helps reduce fuel consumption and reduce the emission of harmful gases into the atmosphere.

Heat engines and environmental protection

Heat engines cause serious damage to the environment. Their widespread use leads to a number of negative effects.

• The dissipation of huge amounts of thermal energy into the atmosphere leads to an increase in the temperature of the planet. Climate warming threatens to result in melting glaciers and catastrophic disasters.• Climate warming is also caused by the accumulation of carbon dioxide in the atmosphere, which slows down the escape of the Earth's thermal radiation into space (greenhouse effect).• Due to the high concentration of fuel combustion products, the environmental situation is worsening.

These are problems on the scale of the entire civilization. To combat the harmful effects of heat engines, it is necessary to increase their efficiency, reduce toxic emissions, develop new types of fuel and use energy sparingly.

Next, I present to your attention the WOT efficiency calculator

so that you can have an idea of which category you belong to:

W.G.R.

WN8

WN6

EFF

xTE

Let's start in order:

WGR is the official rating from Wargaming, a four-digit rating.

Probably the most difficult in terms of pumping up statistics. Here the greatest influence on the efficiency result is exerted by:

Average damage per battle

Average damage due to radio exposure

Average damage due to holding on gusle (it doesn't matter if you deal damage or allies)

————————

wn8 - WN8 rating is more advanced player statistics (reference statistics), in its original form it is four-digit.

The greatest influence on the result is exerted by:

Total player damage dealt

Total number of destroyed

It should be noted here that these statistics are highly dependent on the machine you are playing on, since reference statistics use reference readings for calculations. Roughly speaking, the standard damage of the ISU-152 will be 700. So, if you are playing on this tank destroyer, then you must knock out this same 700 damage from a shot, targeting the enemy’s weak spots or punching into the side and stern. In other words, the closer your damage is to the standard, the higher your statistics. (Note: the number 700 was taken out of thin air...)

————————

wn6 - four-digit efficiency, taken from behind the scenes and developed by American players. Here you will have to work hard to increase this efficiency. The wn6 formula is very large and complex, but we agreed that I will not burden you with formulas, so I will convey the main points. The main thing to remember here is:

base defense points do not greatly affect efficiency;

The first exposure of the enemy also has virtually no effect on efficiency;

Capturing a base is not taken into account at all;

Destroying low-level tanks has less impact on the rating, so choose a tank a couple of levels higher than you and bite;

It turns out that WN6 completely depends on your contribution to the battle

And special attention is paid to the total damage dealt to the player and the total number of tanks destroyed (this takes into account the strength of the enemy you destroyed)

To increase this rating, I would advise you to deal more damage and “take out” more enemy equipment. But not all tanks in the game can do this. For example, self-propelled guns, tank destroyers (top-end and pre-top, as well as French drum tanks). They have the highest damage per minute. The minimum damage per battle for you should be numbers above 1500-2000.

————————

EFF is the good old Efficiency Rating, also known as ER.

For those who are new to the tank, here the greatest influence on the result is exerted by:

Average damage per battle;

Average number of frags (killed opponents) per battle;

Average number of base defense points per battle;

Those. in other words, to increase this efficiency you need to destroy, kill, and also have time to defend your own base! Go for it

————————

xTE is a rating that evaluates your ability to play on a specific tank compared to all other players on that particular tank.

Here, just like in RE, the main thing will be:

Average damage per battle;

Average number of frags per battle;

WOT efficiency