Examples of Oka SUV

Often users turn on their imagination, which amazes the imagination of professional automobile designers. Basically, the alterations differ in design, chassis elements and wheel sizes. Often, low-pressure tires are installed on a car, which improve the vehicle’s off-road capability.

The base of such cars, as a rule, consists of the chassis of other vehicles. To install wheels with a large radius, the wings are cut off; some Oka SUVs undergo body modifications. All manipulations are aimed at giving the car an original and presentable exterior. In addition, craftsmen beautifully straighten and paint the joints.

As an option, you can install protection for the bottom of the all-terrain vehicle. The low-power engine of the original is replaced with more powerful analogues. This is one of the most complex and time-consuming processes when improving a small car. In general, there are modifications that are not embarrassing to present at international exhibitions.

Assembly Features

Important points during assembly:

- During the assembly process, it is imperative to replace the gaskets of the cylinder head, sump, exhaust pipes, and valve cover;

- Tighten the block head bolts in a strictly defined sequence;

- After assembly, perform the adjustment correctly - align the marks of the crankshaft and camshaft to ensure proper operation of the timing belt, tighten the drive belts, check the thermal clearances;

And although there are quite a lot of operations that need to be performed to remove the motor or replace the rings, they are not complicated and all the work can be completed in a day.

How to make an SUV on tracks from the Oka?

Creating such an all-terrain vehicle is quite difficult and expensive. Caterpillars from the Buran all-terrain vehicle are suitable as a running element. You can also make them yourself, but for this you need to have the appropriate skills, materials and time. The drive shafts are also taken from the specified model, since the variable gearbox will be optimally combined with the braking system of the future Oka SUV.

The car's own CV joints will be used. Connecting and connecting the brake discs is not difficult. Identical manipulations are performed on the front shafts. Experts recommend mounting the brake unit in the front of the car. After completing the specified work, the functionality of all main elements and their fastenings is checked. If the first tests do not raise any complaints, you can move on to field testing of the all-terrain vehicle. On some modifications, craftsmen put tracks on each wheel. Among the advantages of this design is the reduction in the total weight of the vehicle. In this case, grip on the road surface will deteriorate.

Modernization of the ignition system of VAZ – 1111 “Oka”

As you know, Oka cars are equipped with a rather imperfect 2-spark ignition system (similar to the options installed on some motorcycles). In general, the use of such a principle of organizing the ignition system cannot be called particularly flawed, however, due to the design features and the not very high quality of individual elements, it has a number of significant disadvantages. In particular, Oka owners are well aware of the existence of problems with starting these cars in winter (even a slightly “supercharged” battery simply cannot cope with maintaining a “push-pull” spark). The state of insulation between the high-voltage and low-voltage circuits of standard double-spark coils does not stand up to criticism either, as a result of which they very quickly fail due to moisture ingress and in damp weather. And, finally, such an unpleasant phenomenon as occasional “shots” in the muffler is also a consequence of the use of a two-spark ignition system - when an incompletely burned mixture is squeezed out by a piston into the intake manifold and, with the valves open, is ignited there by a “non-working” spark.

Be that as it may, the need to modernize the ignition system of the VAZ-1111 Oka is beyond doubt, and currently three main methods are most widespread:

- Introduction into the system of a standard VAZ 2108 distributor with high-voltage ignition distribution, one ignition coil and one switch (from the same place). In this case, two of the four curtains in the spark moment sensor are cut off, or unnecessary spark plugs are fixed in a neutral place in the engine compartment (it is prohibited to leave excess high-voltage wires without discharge).

- Installation of a combined two-spark unit in an imported or domestic version of the “all-in-one” type (switch + coil);

- Installation of the coils of two oil-filled ignition coils from the VAZ 2108, as well as two switches with the combination of their inputs to the output of the torque sensor.

In general, any of these methods allows you to achieve a certain positive result, although each of them is not without some disadvantages. So the first method reduces the overall reliability of the system due to the use of additional elements, namely a high-voltage distributor and several high-voltage wires. The second method is simply to use a more reliable version of the same two-spark system (if you can find decent equipment). Finally, the third method does not eliminate the problem of an “unnecessary” spark and is associated with energy expenditure on the second ignition coil.

Based on the above, it makes sense to carry out a more original and effective modernization, namely, leave only one curtain in the original spark sensor and add a pair of Hall sensors to the system, spaced 180 degrees apart. In other words, it is proposed to implement the third option, eliminating its shortcomings by providing ignition in each of the cylinders using Hall sensors.

Preparatory work

- We are modifying the DMI unit to make it possible to connect two Hall sensors (by replacing the standard connector with a connector with the required number of contacts);

- we cut one of the DMI curtains under the base (the DMI will have to be disassembled), making sure that there are no shavings and crumbs of metal left that could get into the magnetic gap of the Hall sensors;

- we install high-quality injection spark plugs with a gap of 1.1 mm (BOSCH WR7D+X is suitable);

- we use domestic coils, type 27.3705;

- to compactly place the switch one above the other, we machine brass spacers to ensure a distance between the switches of approximately 27mm;

- “HORS” products with silicone caps are suitable as high-voltage wires. We additionally protect the wires from possible overheating with a heat-shrinkable tube.

Implementation Features

To ensure normal operation of the system, the hall sensors must be of the same type (from the same batch), otherwise the direction of the magnets will be disrupted and, as a result, the DMI curtain will be remagnetized. Simply put, you will have to abandon the original sensor.

Power wiring for plus 12V on the relay (in the standard version, blue-black) is carried out with a wire with a cross-section of at least 4 sq mm, while for switches a stranded wire of 2.5 mm is sufficient. It is better not to use standard wiring as there are significant losses on it.

For the signal part, you can take a shielded multi-core cable with a core cross-section of 0.2 mm (the screen will help get rid of interference).

The main difficulty in manufacturing a modernized ignition system is the need to accurately position the Hall sensors on the installation platform. The main problem is that the sensors must be installed with an accuracy of 0.1 mm opposite each other (relative to the circle passing through the centers of their slots). In any case, the sensor mismatch should not exceed 1 degree of crankshaft rotation. If this condition is not met, a significant drop in engine power is observed. For the same reasons, you should ensure that all elements of the system are securely fastened.

The ignition timing is set according to the standard method.

Tags ignition VAZ, OKA VAZ-1111

Similar materials

How to make an all-terrain vehicle from Oka with your own hands?

To make your own unique jeep you will need several basic elements:

- directly the Oka car under the SUV;

- profile pipe for making a frame;

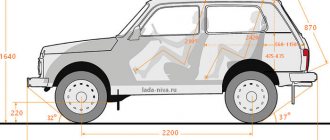

- running gear from Niva;

- steering block, can be from VAZ-2109;

- special tires.

At the first stage, a frame is created from a profile pipe. To begin with, they develop a detailed diagram, after which they entrust the work to an experienced welder, who is guaranteed to ensure the quality of all connections. Next, the transfer case is mounted with its connection to the corresponding mechanisms of the machine.

It is recommended to use springs as a suspension. Springs are not excluded, but they will significantly complicate the frame structure. To mount larger wheels, the fenders are cut off, otherwise it will not be possible to install larger diameter tires. The Niva chassis will ensure ideal off-road performance of the vehicle. After the Oka SUV is ready, test and field tests are carried out in several stages, starting with light off-road and low speeds.

Powerplant removal method

The sequence of work is as follows:

- We put the car in the garage and immobilize it. For the convenience of carrying out some work, we jack up the front end, completely, and not just one side;

- drain technical fluids (oil, coolant);

- We dismantle the carburetor air filter along with the housing;

- Disconnect the throttle and air damper drive cables from the carburetor, as well as the XX solenoid valve wire;

5. Remove the high-voltage wires (from the spark plugs and coil);

6. Disconnect the wiring going to the spark torque sensor;

7. Loosen the clamp securing the gasoline supply pipe to the gasoline pump and remove it;

9. Loosen the clamps and remove the pipes from the thermostat housing that go to the cooling radiator;

10. Remove the pipes leading to the interior heater;

Related link:

Removal and repair of the cylinder head of the Oka car

11. Loosen and disconnect the clutch cable;

12. From the gearbox, disconnect the speedometer drive, the wire of the sensor for turning on the reverse signal, as well as the ground wire put on the stud of the gearbox housing;

13. Disconnect the wiring from the starter and generator;

14. Under the car, loosen the tie clamp at the entry point of the exhaust pipe coming from the manifold into the receiving pipe of the resonator. We move the resonator back, disconnecting the connection;

15. Disconnect the wire leading to the oil pressure sensor;

16. Disconnect the gearshift lever rod leading to the gearbox;

17. Remove the front wheels, unscrew the nuts of the outer CV joint shafts, and pull the hubs off them;

18. Unscrew the bolts securing the steering gear brackets to the subframe;

19. We place the prepared bars under the subframe, after which we carefully lower the jacks, ensuring that the subframe, together with the engine, rests on these bars;

20. Unscrew the bolts securing the subframe to the body;

After this, it is checked whether everything is disconnected, and then, with an assistant, the front end simply rises up (without the motor - it is not heavy) and the body rolls back, and the motor, together with the gearbox, the drive and the subframe, remains lying on the bars.

Well, then further disassembly is carried out, the worn components are rebuilt (for example, replacing the Oka crankshaft), and then the engine is assembled. After the VAZ-11113 engine has been repaired, it is reinstalled in place, for which everything must be done in the reverse order.

Advantages and disadvantages

As user reviews indicate, the all-terrain vehicle in question has not only advantages, but also disadvantages. Among them:

- Increased oil consumption, especially if you practice overcoming water obstacles.

- Rubber on wheels wears out faster.

- Additional inspection of welds is required, since in some cases distortions and other problems with the frame part occur.

It is advisable to coat all parts and mechanisms with a special protective compound or paint them to avoid the occurrence of corrosive processes. If the connections are not sealed, water will enter the machine and cause problems over time.

What can be repaired with the engine removed?

The described method is one of the easiest to perform, since it does not require any special equipment.

Now let’s go over why you should remove the internal combustion engine from a car at all, and what kind of repairs can be done. As already noted, dismantling is carried out in the event of a replacement of the power plant, as well as problems with the crankshaft and CPG.

Related link:

Adjusting Oka valves

One of the frequently performed works is replacing the rings on the Oka. This operation is difficult because it requires almost complete disassembly of the engine to remove the pistons. And it is naturally easier to disassemble it if it is installed on a table or floor, and you can easily turn it as convenient.

Also, all work with the crankshaft is carried out on the removed engine, because removing and installing the crankshaft without dismantling the gearbox is impossible, and while the installation is on the car, the gearbox is practically impossible to remove.

But we note that removing the engine to carry out work on the cylinder-piston group and the crankshaft is a recommendation from the manufacturer. If the matter concerns only the cylinder-piston group (for example, replacement of piston rings or pistons is required) and grooving of the cylinders is not expected, then all work can be performed without removing the engine.

Let's look at how to replace the same rings on an Oka engine without removing it from the car. The tools you will need are the same as those listed above, but it is best to perform the work in the inspection hole.

Owner reviews

User responses to the Oka SUV (see photo in the review) vary. Some people argue that, combined with low cost and high cross-country ability, the improved vehicle can be used on equal terms with UAZs and other domestic all-terrain vehicles. A tracked vehicle is generally capable of overcoming deep ditches and snowy areas. In addition, with skillful modification, the car becomes a real amphibian.

Other users note that the converted Oka consumes a lot of oil and fuel and often breaks down. In addition, rapid tire wear can lead to additional costs. And the transformation of a “compact car” into a jeep itself requires significant costs. Although, this does not stop fans of tuning domestic vehicles. Fortunately, there are still many skilled craftsmen in our country.

Engine tuning

Do-it-yourself tuning of the “Zaporozhets”

Modernization of the Oka engine is conditionally divided into two directions:

- Replacing the motor.

- Improving the characteristics of the standard power unit.

The ideal option for converting the Oka to an injector is to install a 1.3-liter engine from a Rover Mini. Modernization allows you to increase the technical characteristics of the car, but the cost of the work is very high, since most systems need to be redesigned for a new engine.

The second option is to improve the engine. It is cheaper, but does not allow you to achieve such an increase in power as the first one.

Modernization of the Oka engine begins with the carburetor, namely, increasing the diameter of the throttle valve. This facilitates the operation of the motor, increases its service life and technical characteristics. Instead of increasing the throttle, you can immediately install a tuned version of the carburetor.

An increase in the number of revolutions to 7000 units is possible thanks to the installation of a new camshaft. At the same time, the engine power is increased:

- Lightweight valves are installed instead of standard ones.

- Modernization of valve seats;

- Improved valve inlet and outlet ports.

- Sealing.

- Installation of bronze guides.

- Reconstruction of combustion chambers.

The intake and exhaust manifolds are replaced with sports analogues, the air filter is replaced with a K&N model with zero resistance. The work allows you to improve the technical characteristics of the engine and minimize power losses.

In conclusion

It is difficult to imagine that Oka can act as an all-terrain vehicle. Nevertheless, ingenuity and resourcefulness make it possible to create a real off-road conqueror out of this “baby”. Full-fledged Russian-made SUVs, not to mention foreign-made grandees, are very expensive. Converting a “compact car” into an all-terrain vehicle also requires considerable expenses. However, many consumers are confident that “the game is worth the candle.” First, the transformation can be carried out in stages. Secondly, you can easily find spare parts, as well as use improvised means and parts from non-working cars.

Among the most popular homemade versions of the all-terrain Oka, Fr. They are based on low-pressure pneumatic wheels. The originality of the tracked models is that they are perfect for snowy and sandy areas.

Even a basin can become a monster

Tuljak Petr Kozeev accepted the keys to a 2001 VAZ-1113 from the hands of his brother, who inherited the car from his grandfather. The guy took a closer look at the “basin” and decided to make a mini-monster out of it. The transformation took three years.

An updated car with a 0.749 liter engine and 33 hp. accelerates to 100 km/h in 15 seconds. The maximum speed is 130 km/h. Per 100 km it consumes 10 liters of AI-92. The modernization consisted of the following:

- standard wheels were replaced with fashionable hubcaps;

- tinted around;

- aerodynamic qualities have been improved by the Prosport spoiler;

- installed Lada amplifier, 280 W Mistery speakers and Ivolga subwoofer;

- standard instruments were supplemented by a tachometer in a chrome case;

- lighting appeared on the bottom;

- the primitive steering wheel was replaced with a sports R1-sport;

- The body kit with the front grille added elegance to the car.

This new thing cost the 20-year-old driver 23,500 rubles.

Small KAMAZ

Although the development of the small car was carried out in Serpukhov, it was supposed to be launched into mass production in Elabuga, and since the city is located on the Kama River, the model was given the name “Kama” VAZ 1111. But due to the unstable economy then in the Soviet Union, there were no plans not destined to come true - the production of the brand in the planned volume (900 thousand cars per year) did not work out, and the Elabuga plant was repurposed. VAZ-1111 began to be produced in smaller volumes, and at other enterprises:

- at the Volzhsky Automobile Plant in Tolyatti;

- in Serpukhov (SeAZ);

- in Naberezhnye Chelny (ZMA).

Preparatory stage

Most car enthusiasts began to understand the science of driving with the Oka car. But over time, all motorists replace old wheels with new ones, and it turns out that a working, although relatively “old” car is just collecting dust in the garage.

But if you are wondering how to make an ATV from oka, then you have already decided to give your old faithful car a chance at a new life. The assembly process itself will take a certain amount of time, and some parts will need to be purchased, but in the end you can still save a lot on the purchase of a new ATV. In addition, while turning the Oka into an ATV, you will acquire a lot of useful skills and knowledge.

Remodeling Oka's salon according to Feng Shui

The first impression of the interior may seem sparse and insufficient for such a powerful car. Tuning the Oka's interior includes interior firmware, modern upholstery with high-quality material, installation of electric glass lifts and high-quality vibration and noise insulation. Head units, midbass, amplifiers and subwoofer are being updated.

The dashboard is also equipped with sound insulation, and electric lifts can move the windows at the touch of a button. The pedals have aluminum pads, which are often found in sports cars. A loud rectangular muffler will highlight the spirit of sport.

The car has a low degree of passive safety, so this feature needs to be urgently corrected. For the safety of passengers and the driver, install a safety panel and additional airbags. Plus, you can install disc brakes and a dynamic stabilization system.

Sometimes, as an Oka tuning, car enthusiasts purchase starting chargers. Such devices are necessary on the road when the battery runs out randomly. Additionally, you can decorate your car with interesting multi-color airbrushing and vinyl decoration.

Here, give free rein to a professional artist, and he will create a “car” that will surprise and stun everyone on the road. The most popular paintings on the body are in the fantasy style, dark castles, uncharted planets, stars, or the sky.

Thoughtful solution

Since in rural areas you often have to navigate difficult terrain, many people want to buy an SUV. Alas, such cars are quite expensive, so you need to know how to make an all-terrain vehicle from the Oka. To create it, they use improvised means, which include spare parts from broken cars and motorcycles.

Among the most popular options for “folk” crafts are “station wagons” based on low-pressure pneumatics or air-cushioned ones. The use of crawler tracks is also common, but they are more suitable for snowy areas. Creating an SUV based on the Oka is a cost-effective solution, since it does not require the purchase of expensive components.

All-terrain vehicle on low-pressure tires

This design is based on an invention that uses a body that is located on a breakable frame. This solution significantly strengthens the design of the product. All wheels are installed with your own hands as drive wheels, so they can even overcome swampy terrain.

Based on Oka engines, the production of so-called karakat engines is also very popular. They stand out for their increased cross-country ability thanks to wide-format tires. This complements the advantages of pneumatics, because it does not destroy the grass cover.

Using Tracks

These “station wagon” options are most popular among fishermen and hunters. Homemade tracked all-terrain vehicles from Oka have increased maneuverability in water bodies and wooded areas. Their body is usually made of a box structure, which reaches a length of 3 meters. It is light in weight, so in places where deep traces of a person remain, vehicles penetrate into the quagmire only 10 cm.

How to earn points and participate in auctions

You can activate certain functions by exchanging points for items in auctions. But first you need to earn them. To do this, go to the website ok.ru, enter your username and password, and in the menu on the left, find the “OK Moderator” section.

Then click on the “Select game” button.

At the moment there are 3 options for tasks:

- check photographs and videos for the presence of pornography, obscene language and scenes of violence;

- recognize images on stickers;

- note whether there is a phone number in the pictures.

You perform verification and help the administration of the social network monitor various content. Your marks are compared with the opinions of the majority of participants, points are awarded for correct decisions, and points are deducted for mistakes. Select the appropriate option for tasks, read the rules and start completing them.

If you choose the first type of check, keep children away from the screen; some images actually contain pornography.

After you earn at least 200 – 300 points, go to the “Auctions” section.

In the window that opens, we see what features can be purchased for points, the bid for each lot and the auction deadline. It is better to bet on positions that will close soon, then there is a greater chance of becoming a winner.

You can view current lots at any time, the points are saved and will not go anywhere until you spend them. It’s convenient to access “Auctions” through the list of sections on the main page. First, tap “More” and then find the item you want.