In terms of reliability, popularity and prevalence, A-series motors are not inferior to Toyota S-series power drives. The 4A FE engine was created for cars of classes C and D, that is, numerous modifications and restyled versions of Carina, Corona, Caldina, Corolla and Sprinter. Initially, the internal combustion engine does not have complex components and can be repaired and serviced by the owner in the garage without visiting a service station.

In the basic version, the manufacturer provides 115 liters. s., but for some markets it is recommended to artificially reduce the power to 100 hp. With. to reduce transport tax and insurance premiums.

Technical specifications 4A FE 1.6 l/110 l. With.

The markings in the Toyota engine are completely informative, although a little encrypted. For example, the presence of 4 cylinders is indicated not by a number, but by the Latin F, the first letter A indicates the engine series. Thus, 4A-FE stands for as follows:

- 4 – the motor was developed fourth in its series;

- A - one letter indicates that it began to leave the factory before 1990;

- F – four-valve engine design, drive on one camshaft, transmission of rotation from it to the second camshaft, no boost;

- E – multi-point injection.

Distributed injection

In other words, the peculiarity of these engines is the “narrow” cylinder head and DOHC gas distribution pattern. Since 1990, power drives have been modernized to convert them to low-octane gasoline. For this purpose, the LeanBurn power system was used, which allows the fuel mixture to be leaner.

LeanBurn system

To get acquainted with the capabilities of the 4A FE motor, its technical characteristics are summarized in the table:

| Manufacturer | Tranjin FAW Engines Plant No.1, North Plant, Deeside Engine Plant, Shimoyama Plant, Kamigo Plant |

| Engine brand | 4A FE |

| Years of production | 1982 – 2002 |

| Volume | 1587 cm3 (1.6 l) |

| Power | 82 kW (110 hp) |

| Torque moment | 145 Nm (at 4400 rpm) |

| Weight | 154 kg |

| Compression ratio | 9,5 – 10,0 |

| Nutrition | injector |

| Motor type | in-line petrol |

| Ignition | mechanical, distributor |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4 |

| Cylinder head material | aluminum alloy |

| Intake manifold | duralumin |

| An exhaust manifold | steel welded |

| Camshaft | phase 224/224 |

| Cylinder block material | cast iron |

| Cylinder diameter | 81 mm |

| Pistons | 3 repair sizes, original with counterbore for valves |

| Crankshaft | cast iron |

| Piston stroke | 77 mm |

| Fuel | AI-92/95 |

| Environmental standards | Euro 4 |

| Fuel consumption | highway – 7.9 l/100 km combined cycle 9 l/100 km city – 10.5 l/100 km |

| Oil consumption | 0.6 – 1 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30, 15W40, 10W30, 20W50 |

| Which engine oil is best by manufacturer | BP-5000 |

| Oil for 4A-Fe by composition | Synthetics, semi-synthetics, mineral |

| Engine oil volume | 3 – 3.3 l depending on vehicle |

| Operating temperature | 95° |

| ICE resource | declared 300,000 km actual 350,000 km |

| Adjustment of valves | nuts, washers |

| Cooling system | forced, antifreeze |

| Coolant volume | 5.4 l |

| water pump | GMB GWT-78A 16110-15070, Aisin WPT-018 |

| Spark plugs for RD28T | BCPR5EY from NGK, Champion RC12YC, Bosch FR8DC |

| Spark plug gap | 0.85 mm |

| Timing belt | Belt Timing 13568-19046 |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Mann C311011 |

| Oil filter | Vic-110, Mann W683 |

| Flywheel | 6 bolt mounting |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Valve stem seals | Toyota 90913-02090 intake Toyota 90913-02088 exhaust |

| Compression | from 13 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 750 – 800 min-1 |

| Tightening force of threaded connections | spark plug – 25 Nm flywheel – 83 Nm clutch bolt – 30 Nm bearing cap – 57 Nm (main) and 39 Nm (rod) cylinder head – three stages 29 Nm, 49 Nm + 90° |

The Toyota manufacturer's operating manual recommends changing the oil after 15,000 km. In practice, this is done twice as often, or at least after 10,000 miles.

Other engines in the series

4A

The basic model that replaced the 3A series. The engines created on its basis were equipped with SOHC and DOHC mechanisms, up to 20 valves, and the “fork” of output power ranged from 70 to 168 forces on the “charged” turbocharged GZE.

4A-GE

This is a 1.6-liter engine, structurally similar to the FE. The characteristics of the 4A GE engine are also largely identical. But there are also differences:

- GE has a larger angle between the intake and exhaust valves - 50 degrees, in contrast to 22.3 for FE;

- The camshafts of the 4A GE engine are rotated by a single timing belt.

Speaking about the technical characteristics of the 4A GE engine, we cannot mention the power: it is slightly more powerful than the FE and develops up to 128 hp with equal volumes.

Interesting: a 20-valve 4A-GE was also produced, with an updated cylinder head and 5 valves per cylinder. It developed power up to 160 forces.

4A-FHE

This is an analogue of the FE with a modified intake, camshafts and a number of additional settings. They gave the engine greater performance.

4A-GZE

This unit is a modification of the sixteen-valve GE, equipped with a mechanical air pressurization system. 4A-GZE was produced in 1986-1995. The cylinder block and cylinder head have not undergone any changes; an air supercharger driven by the crankshaft has been added to the design. The first samples produced a pressure of 0.6 bar, and the engine developed power up to 145 horsepower.

In addition to supercharging, engineers reduced the compression ratio and introduced forged, convex pistons into the design.

In 1990, the 4A GZE engine was updated and began to develop power up to 168-170 horsepower. The compression ratio has increased, and the geometry of the intake manifold has changed. The supercharger produced a pressure of 0.7 bar, and the MAP D-Jetronic mass air flow sensor was included in the engine design.

The GZE is popular with tuners because it allows the installation of a compressor and other modifications without major engine conversions.

4A-F

It was the carburetor predecessor of the FE and developed up to 95 horsepower.

4A GEU

The 4A-GEU engine, a subtype of GE, developed power up to 130 horsepower. Motors with this marking were developed before 1988.

Design Features

In its series, the 4A FE engine has average performance and has the following design features:

- in-line arrangement of 4 cylinders, bored directly into the body of a cast-iron block without liners;

- two overhead camshafts according to the DOHC scheme to control gas distribution through 16 valves inside the aluminum cylinder head;

- drive one camshaft by a belt, transmitting rotation from it to the second camshaft by a gear;

- distributor ignition distribution from one coil, with the exception of later LB versions, in which each pair of cylinders had its own coil according to the DIS-2 scheme;

- engine options for low-octane LB fuel have less power and torque - 105 hp. With. and 139 Nm., respectively.

DOHC valve timing diagram

The engine does not bend the valves, like the entire A series, so there is no need to do major repairs in the event of a sudden timing belt break.

Technical device

In-line four, four valves per cylinder (16 in total). The block is cast from cast iron; sleeves are not possible due to technical features. The cylinder head is cast from aluminum alloy. Two camshafts (DOCH) are installed and driven by a belt drive. A characteristic feature of the “4A-FE” power unit is that the valve does not bend if the belt drive breaks.

Important! Ignition is carried out by a distributor with one ignition coil (older models had two coils).

List of internal combustion engine modifications

There were three versions of the 4A FE power drive with the following design features:

- Gen 1 – produced in the period 1987 – 1993, had a power of 100 – 102 hp. p., had electronic injection;

- Gen 2 - introduced in 1993 - 1998, had a power of 100 - 110 hp. s, the injection pattern, SHPG, intake manifold has changed, the cylinder head has been modernized for new camshafts, valve cover fins have been added;

- Gen 3 – years of production 1997 – 2001, power increased to 115 hp. With. Due to changes in the geometry of the intake and exhaust manifold, the internal combustion engine was used only for domestic market cars.

Reshaping the intake tract for the Gen 3 modification

The company management replaced the 4A FE motor with a new family of 3ZZ FE power drives.

Tuning

Upgrading the 4A-FE engine is almost useless. It is practically impossible to tune; at best, it is possible to remove 140 hp. But to do this, it is necessary to change half of the engine components and install a turbocharger, which greatly reduces the service life. The 4A-GE model is much better suited for tuning. A charged 240-horsepower turbocharged version was produced. Here is a list of possible modifications for an atmospheric engine:

- Installation of sports camshafts (valve opening phase increased);

- Higher performance injectors and fuel pump;

- Bore the inlet and outlet channels;

- Boring for larger diameter valves, grind the cylinder head.

Advantages and disadvantages

The main advantage of the 4A FE design is the fact that the piston does not bend the valve when the timing belt breaks. Other advantages are:

- availability of spare parts;

- low operating budget;

- high resource;

- the possibility of independent repair/maintenance, since attachments do not interfere with this;

The main disadvantage is the LeanBurn system - in the Japanese domestic market such cars are considered very economical, especially in traffic jams. They are practically unsuitable for RF gasoline, since at medium speeds there is a loss of power, which cannot be cured. Motors become sensitive to the quality of fuel and oil, the condition of high-voltage wires, tips and spark plugs.

Cylinder block 4A-FE

Due to the non-floating fit of the piston pin and increased wear of the camshaft beds, overhauls happen more often, but they can be done with your own hands. The manufacturer used high-resource attachments; the power drive has three modifications, in which the volumes of the combustion chambers are preserved.

List of car models in which it was installed

Initially, the 4A FE engine was created exclusively for cars of the Japanese manufacturer Toyota:

- Carina – V generation in the T170 sedan body 1988 – 1990 and 1990 – 1992 (restyling), VI generation in the T190 sedan body 1992 – 1994 and 1994 – 1996 (restyling);

- Celica – V generation in the T180 coupe body 1989 – 1991 and 1991 – 1993 (restyling);

- Corolla (European market) - VI generation in the E90 hatchback and station wagon body 1987 - 1992, VII generation in the E100 hatchback, sedan and station wagon body 1991 - 1997, VIII generation in the E110 station wagon body, hatchback and sedan 1997 - 2001;

- Corolla (Japanese domestic market) - 6th, 7th and 8th generation in E90, E100 and E110 sedan/station wagon bodies 1989 - 2001, respectively;

- Corolla (American market) - 6th and 7th generation in E90 and E100 station wagon, coupe and sedan bodies 1988 - 1997, respectively;

- Corolla Ceres – 1st generation E100 sedan 1992 – 1994 and 1994 – 1999 (restyling);

- Corolla FX – III generation in E10 hatchback body;

- Corolla Levin – 6th and 7th generation in E100 and E100 coupe bodies 1991 – 2000;

- Corolla Spacio – 1st generation in the E110 minivan body 1997 – 1999 and 1999 – 2001 (restyling);

- Corona - IX and X generations in T170 and T190 sedan bodies 1987 - 1992 and 1992 - 1996, respectively;

- Sprinter Trueno - 6th and 7th generation in E100 and E110 coupe bodies 1991 - 1995 and 1995 - 2000, respectively;

- Sprinter Marino – 1st generation in the E100 sedan body 1992 – 1994 and 1994 – 1997 (restyling);

- Sprinter Carib – II and III generations in E90 and E110 station wagon bodies 1988 – 1990 and 1995 – 2002, respectively;

- Sprinter – 6th, 7th and 8th generations in AE91, U100 and E110 sedan bodies 1989 – 1991, 1991 – 1995 and 1995 – 2000, respectively;

- Premio – I generation in the T210 sedan body 1996 – 1997 and 1997 – 2001 (restyling).

Geo Prism

This engine was installed in Toyota AE86, Caldina, Avensis and MR2; the characteristics of the engine allowed it to be equipped with Geo Prizm, Chevrolet Nova and Elfin Type 3 Clubman cars.

Maintenance schedule 4A FE 1.6 l/110 l. With.

The 4A FE inline petrol engine must be serviced within the following periods:

- The engine oil life is 10,000 km, then the lubricant and filter need to be replaced;

- the fuel filter must be replaced after 40,000 miles, the air filter twice as often;

- The service life of the battery is set by the manufacturer, on average 50 - 70 thousand km;

- spark plugs should be changed every 30,000 km and checked annually;

- crankcase ventilation and adjustment of thermal clearances of valves are carried out at the turn of 30,000 vehicle mileage;

- Antifreeze is replaced after 50,000 km; hoses and radiator must be inspected constantly;

- the exhaust manifold can burn out after 100,000 km.

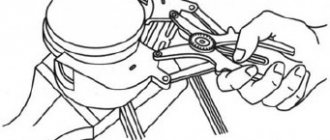

Replacing the timing belt

The initially simple design of the internal combustion engine allows you to carry out maintenance and repairs on your own in the garage.

Engine history

In Russia and around the world, Japanese cars from the Toyota concern enjoy deserved popularity due to their reliability, excellent technical characteristics and relative affordability. Japanese engines, the heart of the concern's cars, played a significant role in this recognition. For several years, a number of products from the Japanese automaker were equipped with the 4A FE engine, the technical characteristics of which still look good to this day.

Appearance:

Its production began in 1987 and continued for more than 10 years - until 1998. The number 4 in the name indicates the serial number of the engine in the “A” series of Toyota power units. The series itself appeared even earlier, in 1977, when the company's engineers faced the task of creating an economical engine with acceptable technical performance. The development was intended for the B-class car (subcompact according to the American classification) Toyota Tercel.

The result of engineering research was four-cylinder engines with power from 85 to 165 horsepower and volume from 1.4 to 1.8 liters. The units were equipped with a DOHC gas distribution mechanism, a cast iron body and aluminum heads. Their heir was the 4th generation, discussed in this article.

Interesting: The A-series is still produced at the joint venture Tianjin FAW Xiali and Toyota: 8A-FE and 5A-FE engines are produced there.

History of generations:

- 1A – years of production 1978-80;

- 2A - from 1979 to 1989;

- 3A – from 1979 to 1989;

- 4A - from 1980 to 1998.

Review of faults and methods for repairing them

Due to its design features, the 4A FE motor is susceptible to the following “diseases”:

| Knock inside the engine | 1) with high mileage, wear of the piston pins 2) with a slight violation of the thermal clearances of the valves | 1) replacing fingers 2) adjusting gaps |

| Increased oil consumption | production of valve stem seals or rings | diagnostics and replacement of consumables |

| The engine starts and stalls | fuel system malfunction | cleaning injectors, distributor, fuel pump, replacing the fuel filter |

| Floating speed | clogging of crankcase ventilation, throttle valve, injectors, wear of the IAC | cleaning and replacing spark plugs, injectors, idle air control |

| Increased vibration | clogged injectors or spark plugs | replacing injectors, spark plugs |

Repair 4A-FE

Gaps with idle speed and engine start occur after the sensors have exhausted their service life or are damaged. Due to a burnt-out lambda probe, fuel consumption may increase and carbon deposits may form on the spark plugs. Some Toyota cars were equipped with engines with the Lean Burn system. Owners can fill with gasoline with a low octane number, but the turnaround time is reduced by 30 - 50%.