The VAZ-415 car with a rotary engine was initially perceived as a comic experiment. According to the developers, the “nine” with such an engine could outrun a Mercedes at a speed of 200 km/h. Nevertheless, there is some part of the truth in this. The power unit in question surpassed all standard modifications of the domestic automotive industry in terms of dynamic and speed parameters. Let's figure out what the advantages and differences of this device are from conventional internal combustion engines.

general information

For the first time in Russia, the VAZ-415 with a rotary engine appeared in 1996 on the basis of the VAZ-2109. The vehicle differed from its competitors in its increased power performance. An experimental 140 horsepower engine accelerated the car to 100 km/h in just eight seconds. At the same time, the speed threshold was about 200 km/h.

The capacity of the fuel tank is 39 liters, fuel consumption has increased noticeably. A full refueling was enough for a trip from Moscow to Smolensk and back. The fact that the car did not go into mass production is explained by its solid “appetite”, as well as its high cost. After the starting prototype, manufacturers released two more copies: versions with 150 and 250 “horses”. The increased dynamics in practical terms did not provide anything useful. The engine, boosted in all respects, became completely unusable after 40 thousand kilometers.

Advantages and disadvantages of rotary engines

Advantages

A rotary engine is good because it consists of a much smaller number of parts

than its competitor - by 35-40 percent.

Two engines of the same power - rotary and piston - will differ greatly in size. Piston twice as big

.

The rotary motor does not experience much load at high speeds

even if you accelerate the car to a speed of more than 100 km/h in low gear.

A car with a rotary engine is easier to balance, which gives increased stability to the car.

on road.

Even the lightest of vehicles do not suffer from vibration, because the RPD vibrates much less than a piston engine.

. This occurs due to the greater balance of the RPD.

Flaws

Motorists would call the main disadvantage of the rotary engine its short resource

, which is a direct consequence of its design. Seals wear out extremely quickly, as their working angle is constantly changing.

The motor experiences temperature changes

every stroke, which also contributes to wear of the material. Add to this the pressure that is exerted on the rubbing surfaces, which can only be treated by injecting oil directly into the manifold.

Wear of seals

causes leakage between chambers whose pressure differences are too great. Because of this, engine efficiency decreases and environmental damage increases.

The crescent shape of the chambers does not contribute to the complete combustion of fuel

, and the speed of rotation of the rotor and the short length of the working stroke are the reason for pushing out gases that are still too hot, not completely burned, into the exhaust. In addition to gasoline combustion products, there is also oil present, which together makes the exhaust very toxic. Piston - causes less harm to the environment.

Exorbitant appetites

gasoline engine has already been mentioned, and it “eats” up to 1 liter of oil per 1000 km. Moreover, once you forget about the oil, you can end up with major repairs, if not an engine replacement.

High price

- due to the fact that the manufacture of a motor requires high-precision equipment and very high-quality materials.

As you can see, the rotary engine is full of shortcomings, but the piston engine is also imperfect, so the competition between them did not stop for so long. Is it over forever? Time will show.

Historical facts

The unique VAZ-415 unit had a rotary engine, which was of interest to Soviet officials back in 1974. Trying to improve momentum in the automotive industry, the government decided to take a big risk. A special design bureau is being created at the plant in Togliatti, the main task of which is to create serial Wankel engines, as rotary units were also called.

Since VAZ models initially copied the Italian Fiat, the engineers in the new version decided to take the Mazda engine as a basis. Domestic injection developments fell into oblivion, although this was the wrong decision, as it turned out later. Soviet officials themselves began negotiations directly with Wankel on the issue of acquiring a license. They were unsuccessful because the designer asked for a huge fee. However, some technologies have been successfully copied.

The pioneer model in this segment was the VAZ-311 with 65 horsepower. The pilot series was released only five years later. 50 copies of the VAZ-415 rotary engine rolled off the assembly line. The models sold successfully among plant workers and government bigwigs.

Appearance

How much does the VAZ-2101 weigh: characteristics

As you know, the “kopek” was built on the basis of the Italian Fiat-124 car. Externally, these cars were practically no different. But as for our modification, the VAZ-21011 had some differences.

So, this car came with a slightly different chrome radiator grille, where there were more frequent vertical lines. And at the bottom of the panel there are four slots. They serve for greater air flow and, accordingly, for better engine cooling. The metal bumper of the VAZ-21011 car lost its characteristic fangs and received rubber linings. There were special openings on the rear pillar that served as exhaust ventilation for the cabin. These holes were covered with the original chrome grilles.

The rear reflectors have been moved to the lights. A reversing light was also integrated into them. On a regular “penny” it was located under the bumper.

Is tuning common among VAZ-21011 car owners? These machines are modified in different ways. Someone makes the engine (we'll talk about modifications to the internal combustion engine a little later), and someone else makes the exterior. If we talk about styling, the “stens” movement has recently become fashionable, supporters of which install original wheels on classic cars and lower the suspension (or install pneumatic ones). Externally, this car looks quite impressive. The reader can see one of these copies in the photo in our article.

Peculiarities

The updated engine did not gain much popularity, since it had only a Japanese lining, and the internals quickly failed. The units had to be changed to piston analogues, in general the idea failed.

Nevertheless, the engine received an unexpected second life. After the next proposal, the plant began production of the VAZ-415 two-section rotary engine with a capacity of 120 horsepower. The resurrected domestically produced unit became so attractive that they began to order it for sports cars and water transport. Vehicles with the specified power units won prizes, far ahead of vehicles with standard pistons. Most likely, it was this fact that became the reason for the ban on the production of this engine. The next attempt at resuscitation occurred after the collapse of the Union in 1996, as mentioned above.

Rotary aggregate and everything connected with it

This motor has constantly attracted and is attracting maximum attention not only in the vastness of our Motherland. And this is not surprising: the design of such a power unit is very simple, and the characteristics seem to be under the hood of not one, but two motors, but, as in our case, this unit has not taken root anywhere. The creator of such a motor is called Wankel, who managed to come up with this design back in 1919. Wankel was German and at the age of 17 he created a miracle. How he managed this remains a mystery. DKM or “machine with rotating pistons” is the name given to the first car with a rotary unit, the first patent for which Wankel received in 1929.

Advantages

The VAZ-415 rotary engine, the photo of which is presented below, has become an excellent alternative to a forced engine. Among the advantages:

- stable power indicator throughout the entire operating range;

- huge potential for chip tuning;

- high efficiency;

- speed up to 10,000 rotations per minute.

The operating principle of the unit in question differs from a standard internal combustion engine. First of all, this is due to the presence of a rotor, which performs the duties of a connecting rod and piston. The incoming energy from fuel combustion provokes the rotation of the shaft at high speed. Inlet and outlet occur in a single compartment, the inside of which resembles a capsule. The rotor was mounted on a shaft and was firmly engaged with a gear, which is connected to the stator.

Advantages and disadvantages

The converted movement of a reciprocating nature is completely absent in a rotary engine. Pressure is generated in those chambers that are created using the convex surfaces of the triangular rotor and various parts of the housing. The rotor performs rotational movements with the help of combustion. This can reduce vibration and increase rotation speed. Due to the increased efficiency that results from this, the rotary engine is much smaller in size than a conventional piston engine of equivalent power.

A rotary engine has one main component among all its components. This important component is called a triangular rotor, which rotates inside the stator. All three vertices of the rotor, thanks to this rotation, have a constant connection with the inner wall of the housing. With the help of this contact, combustion chambers are formed, or three closed-type volumes with gas. When the rotor rotates inside the housing, the volume of all three formed combustion chambers changes all the time, reminiscent of the actions of a conventional pump. All three side surfaces of the rotor act like a piston.

Inside the rotor is a small gear with external teeth, which is attached to the housing. The gear, which is larger in diameter, is connected to this fixed gear, which sets the very trajectory of the rotational movements of the rotor inside the housing. The teeth in the larger gear are internal.

Due to the fact that the rotor is connected eccentrically to the output shaft, the rotation of the shaft occurs in the same way as a handle would rotate a crankshaft. The output shaft will rotate three times for each rotor revolution.

The rotary engine has the advantage of low weight. The most basic of the rotary engine blocks is small in size and weight. At the same time, the controllability and performance of such an engine will be better. It has less weight due to the fact that there is simply no need for a crankshaft, connecting rods and pistons.

The rotary engine has dimensions that are much smaller than a conventional engine of the same power. Thanks to the smaller engine size, handling will be much better, and the car itself will become more spacious, both for passengers and the driver.

All of the parts of a rotary engine perform continuous rotational movements in the same direction. Changing their movement occurs in the same way as in the pistons of a traditional engine. Rotary engines are internally balanced. This leads to a decrease in the vibration level itself. The rotary engine's power feels much smoother and more even.

The Wankel engine has a special convex rotor with three edges, which can be called its heart. This rotor performs rotational movements inside the cylindrical surface of the stator. The Mazda rotary engine is the world's first rotary engine that was developed specifically for mass production. This development began back in 1963.

Device

The rotary power unit of the VAZ-415 is made in the shape of a triangle. When moving inside the block, each end of the structure is separated by a certain amount of space. In this engine, the role of piston rings was played by special plate elements, pressed to the walls using belt-type springs, centrifugal force and exhaust gas pressure.

The design of the Wankel internal combustion engine does not include a timing belt, which significantly simplifies the design of the device. Since friction losses in this unit are minimal, it was possible to achieve a significant increase in power. Three working cycles were carried out during one full revolution.

The disadvantages of rotary engines include high fuel consumption. This is due to the fact that the combustion compartment during the compression stroke is too long, which does not allow the gasoline to burn out completely. To level out this drawback, they began installing two spark plugs on the engines, firing alternately. This approach made it possible to increase the efficiency of the updated modifications.

Priora engine 21126 16 valves VAZ 2106 2107 2101 classic

VAZ 2101

It is taken from the usual “twelve”. All sensors are installed. Now they should be connected. To do this, it is advisable to carefully study the same VAZ 2107. The ideal option would be to lay the wires the way they are located there. Don't forget to connect the "check". If you don’t have it on your panel, you will have to change the torpedo to a “seven” one. Some drivers take a different route. If there is no special lamp, simply install an additional LED and connect a wire from the ECU to it. After final assembly, the control unit should be programmed. And make the final settings.

Desirable improvements

. The engine from the VAZ 2112 is more powerful. Accordingly, the car will accelerate faster and stop slower. To avoid problems on the road, it is advisable to modify the brake system. To do this, install a more powerful master cylinder, as well as working cylinders. At this point, the tuning of the Lada can be considered complete.

Conclusion

. Tuning classics is quite common in our country. At the same time, many people who are planning to modify their Lada cars are interested in the question of how legal it is to install a 16 valve engine on a classic? In theory, such a change in design should be registered. But recently, the motor is considered a part, and its number is not even indicated in the documents. Therefore, you can safely put it under the hood of a classic. This will not even affect the technical inspection.

Home / Car catalog / Technical characteristics of VAZ 2101

Characteristics of VAZ-415

Brief parameters of the Wankel engine:

- number of sections - 2 pieces;

- power indicator - 140 hp. With.;

- unit weight - 113 kg;

- working chamber volume - 1.3 cubic meters. dm;

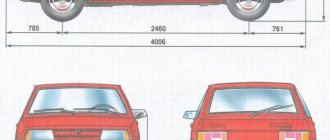

- overall dimensions - 570/535/665 mm;

- working life before major repairs - 125 thousand km.

It is worth noting that fuel supply, shaft rotation and other operating operations occur in a single unit, which is the combustion compartment and timing section.