Where is the fuel pressure regulator located?

A diaphragm valve-regulator, which is subjected to fuel pressure on one side and spring force on the other, is used to more accurately dose fuel and maintain constant pressure in the system. A VAZ fuel pressure regulator of this type is installed in those systems that have a return line. In them it is located in the fuel rail. Less commonly, the part is installed in the fuel tank, but such systems do not have a return line. How the fuel pressure regulator works depending on its location is described below.

Location of the regulator in the fuel rail

One of the most common placement schemes: the VAZ fuel pressure regulator is located on the fuel rail. The principle of operation of the element is to pump fuel through the line from the fuel tank using a fuel pump. The regulator is under pressure from the fuel. The RTD itself consists of two separate cavities-chambers, separated by a membrane: a fuel chamber and a spring chamber. Through special inlet holes, fuel enters the regulator, which puts pressure on the membrane on one side; on the other hand, a spring and the pressure of the intake manifold presses on it. If the fuel exerts greater pressure than the spring force and inlet pressure, then the regulator opens, due to which part of the fuel is discharged into the “return”. Excess fuel is sent back to the fuel tank via the return line.

Location of the regulator in the fuel tank

The RTD is placed directly in the fuel tank in systems that do not have a return line. The advantage of such a system is the absence of an additional pipeline. The required volume of fuel is supplied directly from the tank, that is, excess fuel does not accumulate in the engine compartment, and accordingly, there is no need to send it back to the tank. Thanks to this design, the fuel does not overheat and evaporates less, which is an additional advantage.

Electronic circuit for regulating fuel pressure

The fuel pressure in the system is adjusted using an electronic circuit, the design of which does not imply the presence of a mechanical regulator. The pressure in such systems is controlled by an electric fuel pump. The electronic control system installed in it records the voltage and regulates the volume of supplied fuel. The advantages of using a fuel pressure regulator sensor are maximum savings and reduced fuel heating.

Only a strictly limited amount of fuel is supplied to the engine injectors, necessary for the selected operating mode of the engine and the specific conditions of its operation. Excess pressure does not rise to a critical level due to the presence of a relief valve.

What does P0087 mean?

Trouble P0087 is a general trouble code that indicates that the engine control module (ECM) has detected a problem with the fuel delivery system. This error will appear if the vehicle's ECM receives a signal from the fuel pressure sensor indicating that the fuel pressure is too low.

When a P0087 error occurs, the Check Engine light on your vehicle's dashboard will illuminate, indicating that there is a problem. The ECM will also put the vehicle into limp mode to prevent further damage. The vehicle will remain in this mode until the error is resolved.

The main symptoms of fuel pressure regulator problems

When diagnosing the engine power system, it is necessary to take into account the signs of a malfunction of the fuel pressure regulator. The main symptoms associated with RTD problems are a decrease in engine power and its inability to reach the required speed. Signs of a malfunction of the fuel pressure regulator and, accordingly, the engine are as follows:

- The engine idles unsteadily and stalls.

- Fuel consumption increases, power decreases.

- The engine responds slowly to the accelerator pedal.

- When accelerating the car and when changing the throttle, jerks and dips appear.

- The car does not gain speed and does not accelerate.

Signs and symptoms of low pressure in the system

Weak pressure is expressed primarily by the presence of dips. You try to accelerate, press the gas pedal, nothing happens. Stopping the engine and then starting it helps (this way the pump pumps fuel). However, after ten or fifteen kilometers the situation repeats itself.

Some drivers even change the fuel filter or pump strainer in the hope of improving the situation, but this does not help. Replacing the mesh in this case is considered as a more correct option. The fact is that the pressure can drop due to a poorly functioning pump.

If the problem is not in the mesh, then the pump itself is dying. There is another reason - it is the vacuum of the fuel tank. This is how it is checked. You need to stop the car if it starts leaking, sneezing, etc. But don't turn off the engine. Then open the tank flap and loosely close it again. Continue driving, if the dips disappear, it means there is definitely a vacuum in the tank.

The lid may not be closed at all to allow air access. When there is a vacuum it is not enough. If the problem repeats, the failures do not disappear, the fuel pump must be considered the culprit.

A clogged fuel line and a malfunction of the sensor that regulates the fuel pressure immediately before injection can also cause low pressure. To reliably verify why exactly the pressure is jumping, it is necessary to carry out competent measurements. First measure the pressure of the pump, then the lines (before and after the filter), and then directly in the ramp. Such instrumental monitoring will allow us to identify a specific cause.

RTD defects: spring

The main problem with the regulator is the weakening of the spring, which causes premature draining of fuel into the return line. This leads to starvation of the engine: it does not have enough fuel to operate at high speeds, when the accelerator pedal is pressed, or in transient modes. A faulty regulator spring causes low fuel pressure in the fuel rail, which leads to a decrease in engine power, problems with the ECU and unstable operation of the engine.

Where to start checking?

As you can see, there are many reasons for a drop in pressure in the fuel line, so diagnostics should be carried out sequentially: fuel filter - pump - fuel injectors - electrical harnesses and connectors (yes, sometimes the source of problems is poor contact) - lines (high and low pressure) - all other elements of the system.

It’s even better to follow not general recommendations, but rely on the experience of other owners of your car brand, because each car, be it Ford, Mercedes, Audi or others, has its own weak points and features of the fuel system.

RTD contamination

Another malfunction of the regulator is its contamination and reduced throughput. In this case, the engine stalls regardless of which specific operating mode is selected. If the regulator is heavily contaminated, the pressure in the system increases sharply, and this can lead to fuel escaping through the sealing parts and joints. Vehicle manufacturers always consider the possibility that injector and fuel pump performance will deteriorate over time. This problem is solved by pumping more fuel into the fuel pump. Excess fuel increases pressure if it cannot return back to the return line.

How serious is P0087?

Error P0087 is quite serious, as when it appears, problems with the vehicle's handling may occur. If the fuel pump fails or the fuel filter is severely clogged, the car's engine may suddenly stall, which in turn can lead to dangerous situations on the road. Also, when this error appears, misfire in the engine cylinders, a drop in power, or unstable engine operation when accelerating the car are possible. If this code is detected, it is recommended that you contact a qualified technician as soon as possible to diagnose and resolve the error.

Regulator jammed

The pressure regulator located in the fuel rail may begin to jam at certain intervals. Symptoms of such a problem include pressure drops in the system and jerking of the car. Another sign of a faulty fuel pressure regulator, which is no less common, is the banal wear of all parts: in other words, over time the valve completely exhausts its life. The service life of this engine element depends on the quality of the fuel, the presence of various impurities in it, the operating mode of the vehicle itself and many other factors.

Signs of a fuel pump malfunction

Engine won't start

This is the main symptom of a faulty fuel pump. In the summer heat, a dying fuel pump may appear. The junction of the impeller with the rotor axis expands, and it rotates. You should check the fuel pressure from the rail and from the pump directly.

The service life of the fuel pump is determined by the owner's use of the vehicle. What is required for the fuel pump to last longer and not fail:

- Check the presence of water in the tank. For prevention, pour any pure alcohol into the tank. It mixes with water and burns out through the exhaust. There is a moisture displacer available in stores. Contains isopropyl alcohol.

When purchasing other displacers or desiccants, carefully read the ingredients, as there may not be alcohol, but other chemical compounds may be present that will clean the tank and clog the injectors.

- It is advisable to have a fuel level of at least half the tank. This minimizes the water-gasoline ratio and the pump cools better.

- Change the fuel pump mesh every 30,000 km, and the fine filter (barrel) every 15,000 km. It is in this filter that all sediments and water accumulate. Causes of pump failure due to compressed water mesh are a common occurrence.

The car does not accelerate well

Loss of traction when the fuel pump fails is a fairly common symptom number two. The cylinders begin to work poorly, there is no normal injection by the nozzle, and ignition of the mixture becomes ineffective. The injector produces an uneven spray, and the flow rate of the mixture into the combustion chamber drops. Thus, if the electric fuel pump fails, the engine power is reduced.

If there is a loss of traction, the fuel pump does not necessarily break down. You need to check the filter, fuel line, and fuel pressure regulator for blockages.

Fuel pressure regulator diagnostics

In terms of its symptoms, a malfunction of the RTD is in many ways similar to malfunctions of the fuel filter or fuel pump. It is worth noting right away that if, during diagnostics of the fuel system, faults were found in the RTD, then the optimal way out of the situation would be to replace the fuel pressure regulator. This is explained by the fact that replacing individual parts, washing and cleaning the device will not return it to full functionality. Considering that the cost of the RTD is very affordable and acceptable, repairing the fuel pressure regulator is simply impractical.

You can diagnose the RTD yourself in one of the simplest and most effective ways: check the fuel pressure in the fuel system. This is done using a pressure gauge. It is measured with the engine idling; The pressure gauge is connected in parallel with the vacuum hose between the fitting and the fuel hose.

The measurements taken show pressure fluctuations in the system. It should increase, while being in the range from 0.3 to 0.7 Bar. If such indicators were not detected, then it is necessary to reconnect the fuel pressure regulator hose and reuse the pressure gauge. The fitting plug is unscrewed to measure the fuel pressure at the end of the fuel rail. The plug has a special sealing ring: you need to check it for integrity - it should not be elastic. If there are still defects on it, then it is changed either separately or together with the plug.

Car owner experience.

I had this: when cold it only gave 5 atmospheres, I warmed up the car, gave it a little gas on the spot - everything stabilized. The fault was with the spark plugs or the ignition system, but over time the situation only began to worsen. It got to the point that the car started working normally only after a restart with the throttle turned up to 2 thousand rpm. When one day on the road the emergency mode turned on - the engine simply did not spin up above 2000 rpm, I decided to do some diagnostics. She showed P0087. After a long search for its possible sources on the Internet, I began a detailed check of the injection pump and was not mistaken; after replacing the element, all the problems disappeared.

For me, the reason for the lack of fuel and the appearance of P0087 in the service was called a dead pump, pusher and camshaft. If they solved the pusher problem promptly by installing a used part of acceptable quality, then replacing and repairing everything else with ordering spare parts would cost a decent amount. I would like to note that the stock camshaft had a very noticeable wear, perhaps even due to insufficient hardening of the metal by the automaker. Today you can no longer buy such a shaft with the original number; there is only an analogue with a slight change in markings. I bought it. The car came to life.

If you have difficulty starting your Peugeot 3008 cold, the first thing to do is change the pushrod, regardless of whether you have diesel or gasoline. This is the weak point of the brand. After driving 70 thousand km (turbocharged engine, 156 horses), problems began: the car started up quickly, but then began to stall, the check light came on, and sometimes the fan was even forced to turn on. The service center said that the fuel injection pump needs to be replaced. I didn’t argue, the problem went away.

The Check Engine light was constantly on in my car, the diagnostics showed P0087. When the fault memory was reset, the error came on again. I looked at the ECU data and it turned out that both the pump produces consistently high pressure (5-6 bar) and the rack (about 4.5 bar). I checked the sensor - it works. I took out the high pressure pump and it looked like new. I tried to squeeze its spring, but I couldn’t do it either with my hands or with a vice. I put the car in gear and rolled it back until the cam on the camshaft turned toward the fuel injection pump with its maximum protrusion. I inserted the pump into it and it sat there without the slightest effort. I concluded that the plunger of the part does not reach the glass. I measured the spring protrusion - 15 mm. I went to the spare parts store and measured this protrusion on the new part - 22 cm. Everything became clear. I replaced the pump and the error no longer appeared.

I really liked the Citroen brand, it’s inexpensive and easy to maintain. Recently I started getting errors P0087 (fuel pressure below the set value) and P0093 (the set pressure differs from the measured one). I immediately knew that I needed to look for the problem in the injectors or pressure regulator, and if not, in the wiring or sensor. The named nodes are the weak points of the model. I was right, the injectors broke. Timely, high-quality repairs helped restore the car to its former strength and give me peace of mind.

Once I was traveling to another city on business, and some funny things started happening along the way: the car stalled, the battery and check lights came on. With grief in half I arrived at some service center, they couldn’t do or say anything intelligible, thank you, at least they erased all the mistakes so that I could get back. By the way, it was not easy to do this; some kind of emergency mode probably turned on, because... Although the Passat was driving, it apparently did so with the last of its strength - under high loads the ignition would fail. In Moscow, I again went to the first service station I came across, they carried out diagnostics, identified error P0087 and immediately ordered the fuel pump to be replaced. To be honest, this speed and the price of the issue bothered me a little, since I have repeatedly heard that it is not the pump that is the problem with the Passat, but the mesh in it. I called some garage guys I knew and they decided to double-check everything themselves. Yes, the error was the same, but they didn’t force me to change the entire assembly at once. We measured the pressure, it turned out that instead of 150 bar, it gave 80 and was cut off. It’s clear, that’s definitely the issue. For half an hour, the guys disassembled my non-separable fuel pump. Then they took out the same mesh clogged with dirt (although I only refuel with AI98 G-drive from Gazprom). They replaced it and put everything back together. Now the car drives like new again, and I saved about 17 thousand rubles.

This is interesting: EGR valve: what is it, principle of operation, main malfunctions

Recently, I also encountered a low pressure supply: while driving, the car suddenly stopped moving, and at idle the speed fluctuated. Diagnostics returned P0087. Fortunately, my friend had already encountered this - shavings from the injection pump killed the injectors, and they flowed into the return line. The result was that I changed everything that came into contact with fuel. I did it simpler - I replaced the filter, the leaking injectors and sold the car, let the new owner have fun.

I would like to advise all Mercedes owners, when carrying out physical repairs of a fault, do not forget about the “brains” of the car! A couple of months ago I encountered a problem with loss of traction, everything is fine at idle, but I can’t accelerate normally. I'm tired of driving to different service stations - they only named one error, P0087, but the solutions were different, including the price. I replaced the fuel pressure sensor on the ramp, the pipelines, and washed the particulate filter. The result is 0. Then smart people suggested that it is not enough to fix the problem, you also need to reflash the ECU. I did so, and the problem finally went away.

What happens if you don't fix the problem?

The faster the problem is fixed, the better. Problems in the fuel system can lead not only to poor vehicle handling, but also to a possible fire. Therefore, it is recommended to find out in advance what pressure should be in the fuel system:

- the pressure when turning the key should be within 3 atmospheres;

- if the car is idling - 2.4-2.5 atmospheres;

- when squeezing the drain hose - about 7-8 atmospheres with a working ramp;

- when you press the gas, it first rises to 3 atmospheres, then drops to 2.5.

Fuel pressure regulator repair

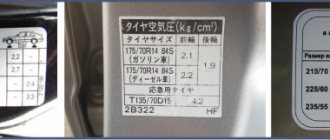

After the diagnostics of the system is completed and the sealing ring is inspected, the umbrella is unscrewed from the fitting. You can unscrew it using the metal valve cap. The pressure gauge hose is then connected to the fitting, then the entire structure is secured using clamps. Pressure measurements are carried out only when the engine is running. Standard pressure readings should be 2.9-3.3 kg/cm2. Then the hose is carefully disconnected from the fuel pressure regulator, and the pressure gauge readings are recorded: the pressure should increase to 70 kPa from 20 kPa.

The fuel pressure regulator is changed if the readings remain too low or zero. Replacing this part is not difficult: you can do it yourself in a regular garage. Before starting the procedure, all pressure is released from the engine power system. To do this, unscrew the nut securing the fuel pipe, after which the bolts that secure the regulator itself to the fuel rail on most cars with injection engines are unscrewed.

Subsequently, the regulator fitting is carefully removed from the hole in the fuel rail, after which the RTD is completely dismantled. Before this, the fuel pipe is completely disconnected. The last stage is the installation of a new or working regulator into the ramp, after which the functionality and serviceability of the entire fuel system is checked using a pressure gauge.

Before installing a new fuel pressure regulator, experts recommend lubricating the O-rings with gasoline: this will make installation of the new part easier. A similar procedure is performed when replacing the o-rings themselves.